Design Method of Vibration Reduction for Suction and Discharge Pipeline of Rotary Compressor

A design method and compressor technology, applied to mechanical equipment, rotary piston type/oscillating piston type pump components, machines/engines, etc., can solve pipeline refrigeration system vibration, pipeline fatigue damage, long pipeline design cycle To achieve the effect of vibration reduction design and reduce the transmission of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings of the specification, and specific implementation manners will be given.

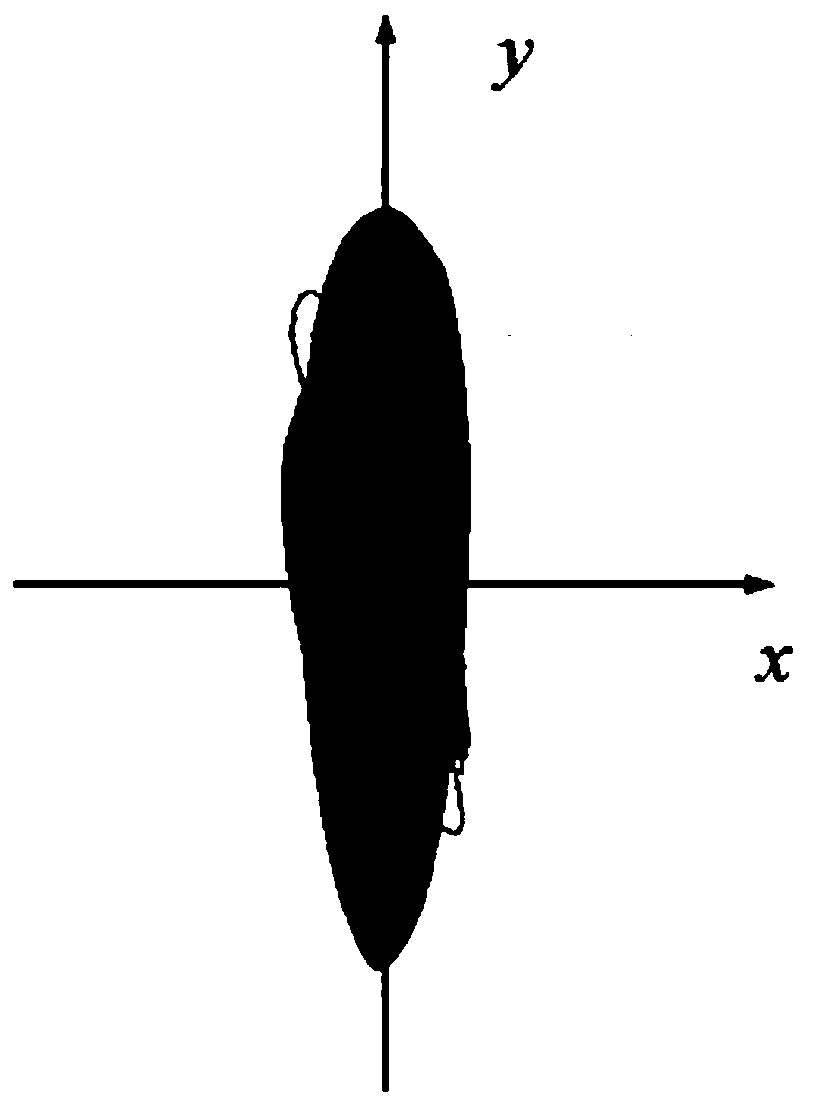

[0021] Such as Figure 1-5 As shown, the design method for damping vibration of the suction and exhaust pipelines of a rotor compressor includes:

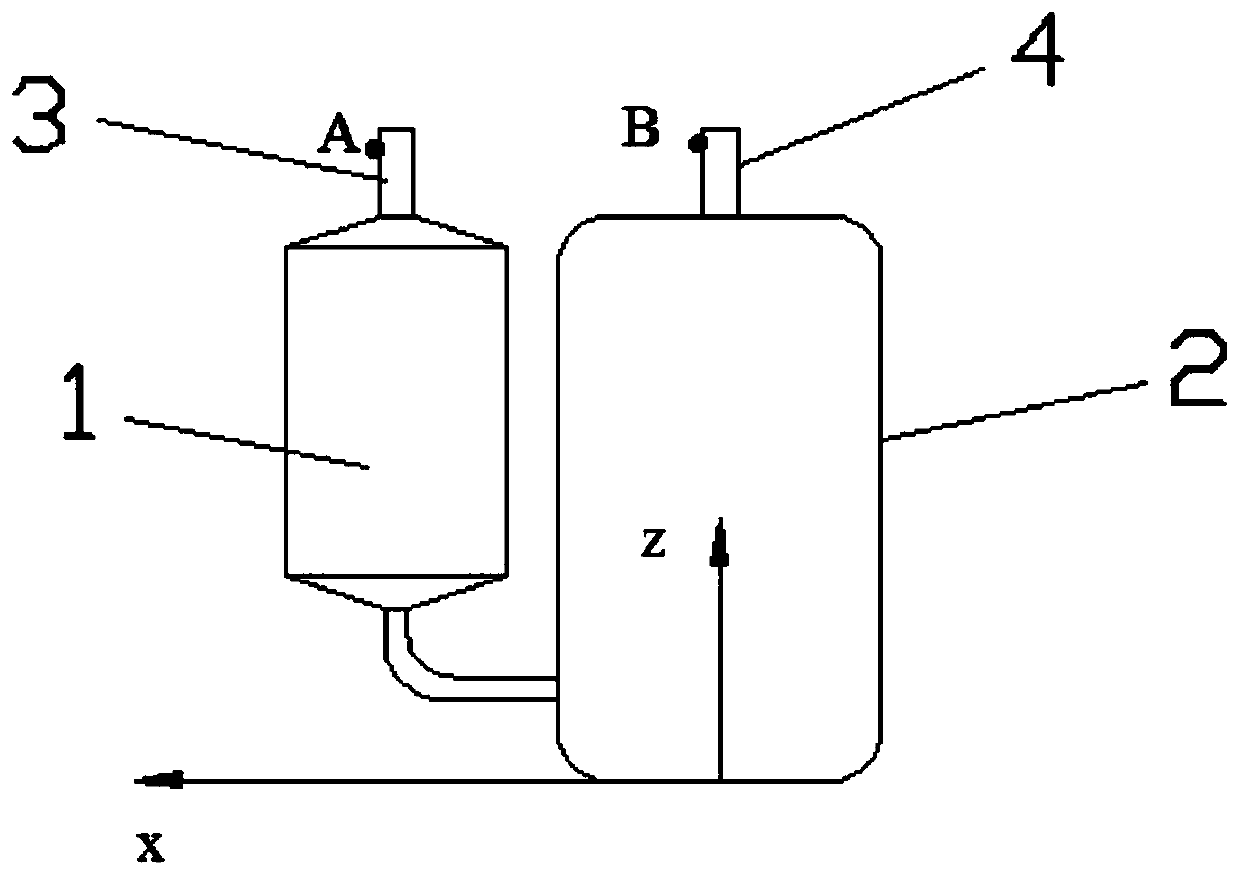

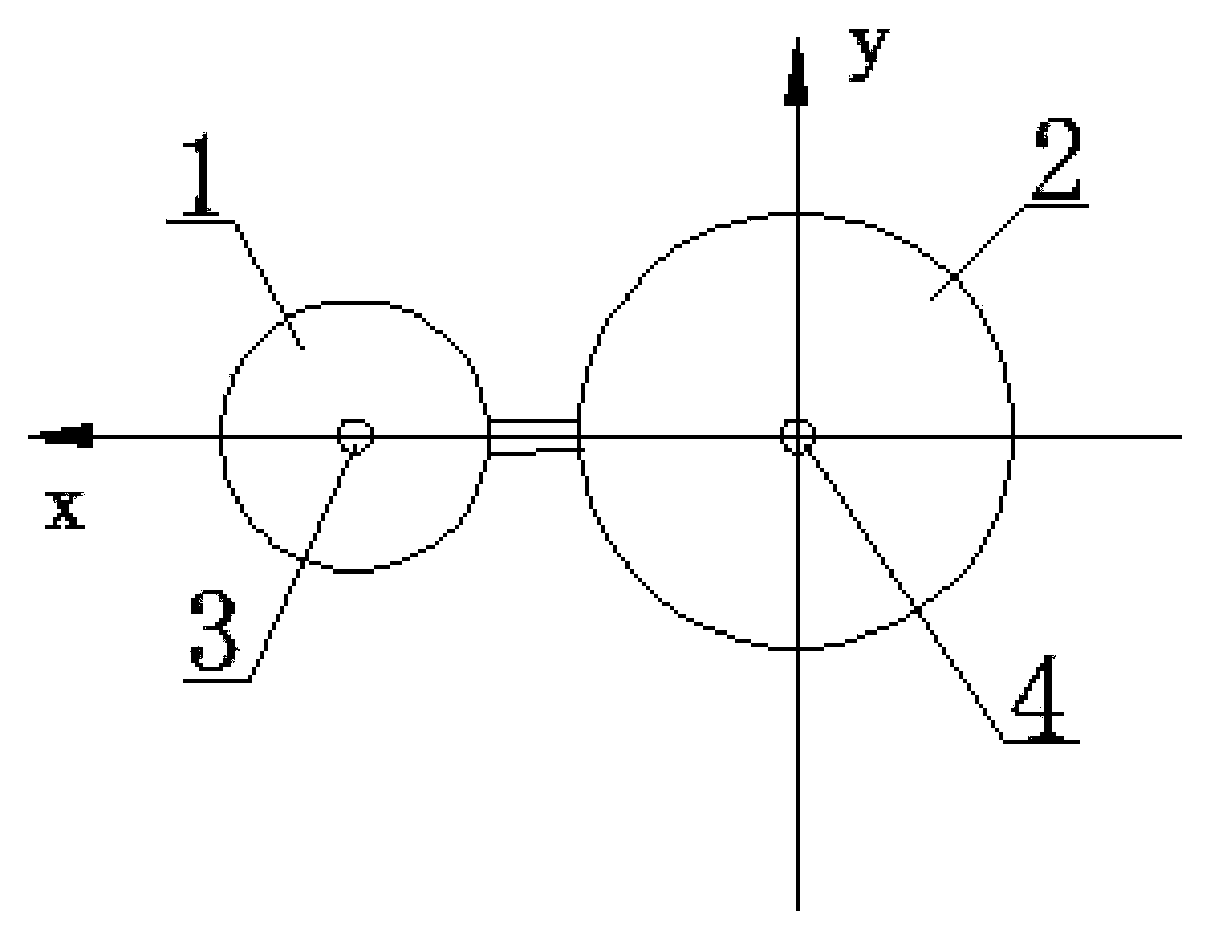

[0022] a. Design a vibration test system according to the suction and discharge pipelines of the rotor compressor. The rotor compressor includes a connected liquid storage tank 1 and a compressor rigid body 2. The top center of the liquid storage tank 1 is provided with a suction port 3, the compressor rigid body 2 The top center is equipped with an exhaust port 4. The rotor compressor is also connected with refrigeration equipment through pipelines. The refrigeration equipment is used to control the pressure conditions of the suction and discharge of the rotor compressor; the vibration test system includes a frequency conversion controller an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com