A temperature-measuring dipping preheating furnace and a temperature-measuring method

A technology of preheating furnace and temperature measuring device, which is applied in the direction of preheating cost, furnace, furnace components, etc., and can solve the problems of lengthening preheating time, processing influence, and difficult impregnation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

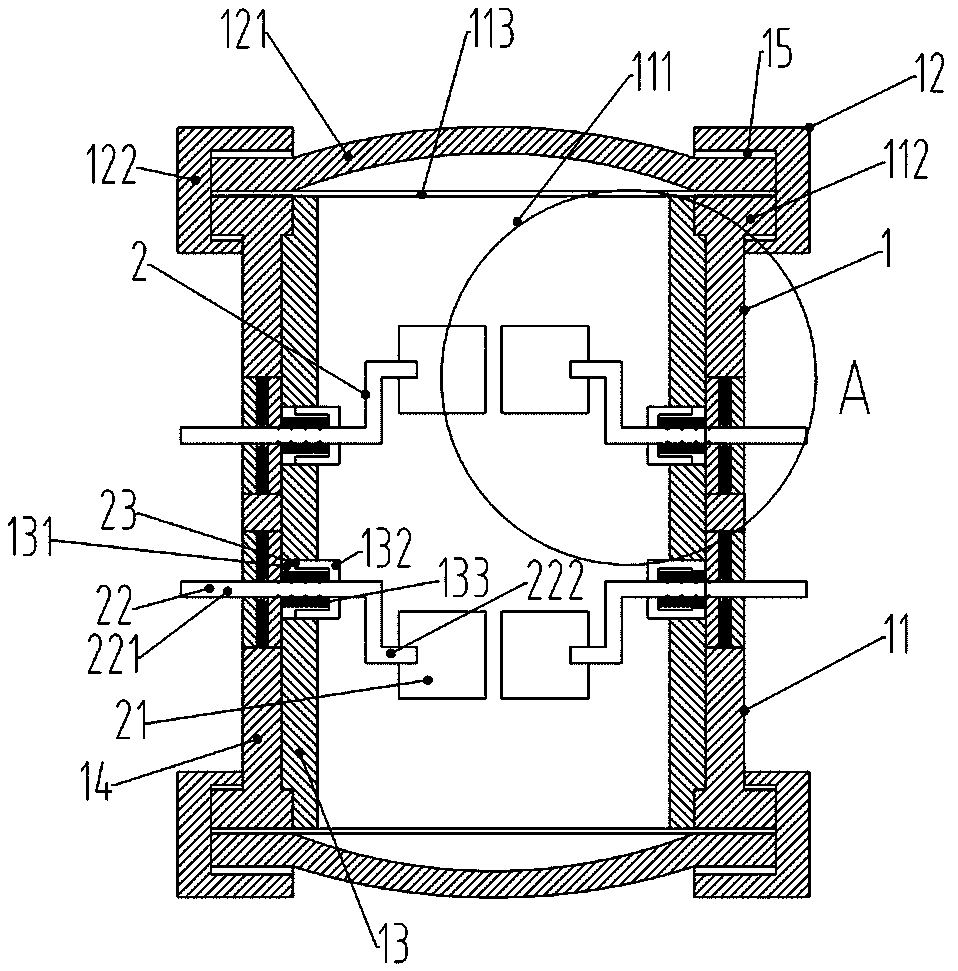

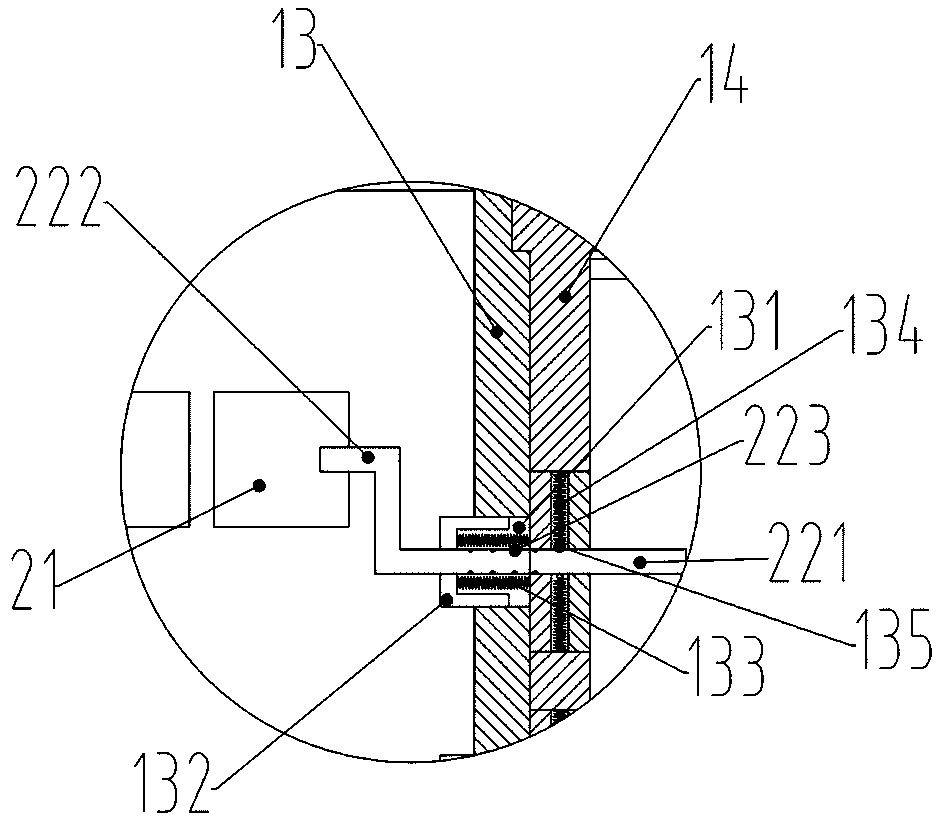

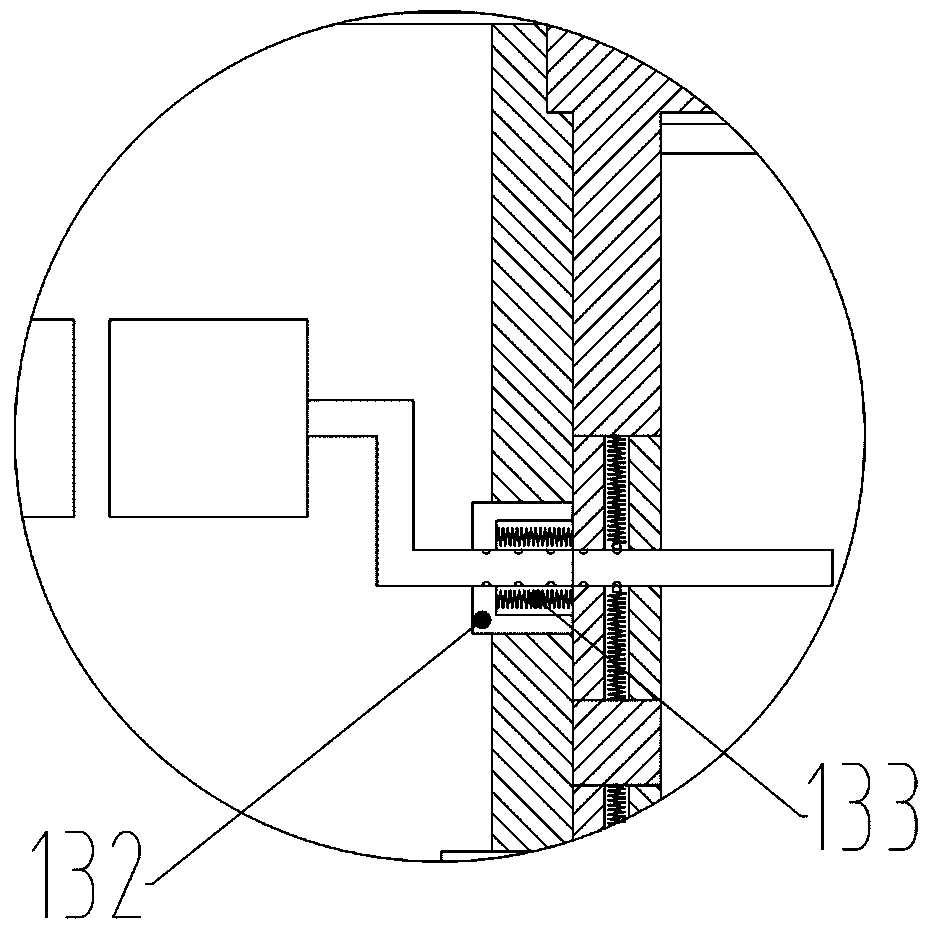

[0029] see figure 1 , is an overall schematic diagram of a temperature-measuring dipping preheating furnace provided in an embodiment of the present invention. It is characterized in that the temperature-measuring dipping preheating furnace includes a dipping preheating furnace 1 and a temperature measuring device 2. the interior of the furnace 1;

[0030] The immersion preheating furnace 1 comprises a immersion preheating furnace main body 11 and a sealing device 12, the sealing device 12 is arranged on both ends of the immersion preheating furnace main body 11, the immersion preheating furnace main body 11 is in the shape of a hollow cylinder, and the immersion preheating furnace main body 11 The interior of the temperature measuring device is provided with a chamber 111, and the temperature measuring device 2 is arranged in the chamber 111 of the temperature measuring device. The sealing device 12 includes a sealing cover 121 and a fastening ring 122. The bottom of the seal...

Embodiment 2

[0037] The temperature measuring immersion preheating furnace provided for the embodiment of the present invention includes an immersion preheating furnace 1 and a temperature measuring device 2, and the temperature measuring device 2 is arranged inside the immersion preheating furnace 1;

[0038] The immersion preheating furnace 1 comprises a immersion preheating furnace main body 11 and a sealing device 12, the sealing device 12 is arranged on both ends of the immersion preheating furnace main body 11, the immersion preheating furnace main body 11 is in the shape of a hollow cylinder, and the immersion preheating furnace main body 11 The interior of the temperature measuring device is provided with a chamber 111, and the temperature measuring device 2 is arranged in the chamber 111 of the temperature measuring device. The sealing device 12 includes a sealing cover 121 and a fastening ring 122. The bottom of the sealing cover 121 is in contact with the dipping preheating furnac...

Embodiment 3

[0044] The temperature measuring immersion preheating furnace provided for the embodiment of the present invention includes an immersion preheating furnace 1 and a temperature measuring device 2, and the temperature measuring device 2 is arranged inside the immersion preheating furnace 1;

[0045] The immersion preheating furnace 1 comprises a immersion preheating furnace main body 11 and a sealing device 12, the sealing device 12 is arranged on both ends of the immersion preheating furnace main body 11, the immersion preheating furnace main body 11 is in the shape of a hollow cylinder, and the immersion preheating furnace main body 11 The interior of the temperature measuring device is provided with a chamber 111, and the temperature measuring device 2 is arranged in the chamber 111 of the temperature measuring device. The sealing device 12 includes a sealing cover 121 and a fastening ring 122. The bottom of the sealing cover 121 is in contact with the dipping preheating furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com