Drying device for production of calcium hypochlorite

A drying device and calcium hypochlorite technology, applied in heating devices, drying solid materials, dry cargo handling, etc., can solve the problems of uneven mixing, single function, rigid structure, etc., to improve product quality, prolong heating time, The effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

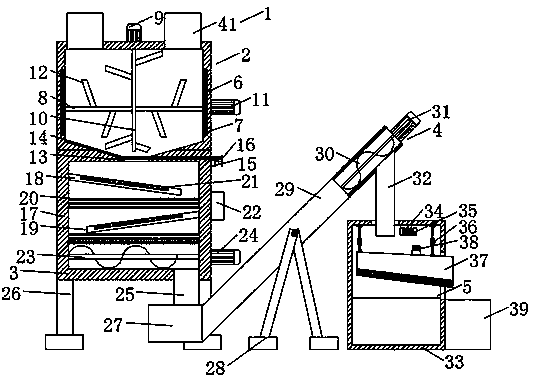

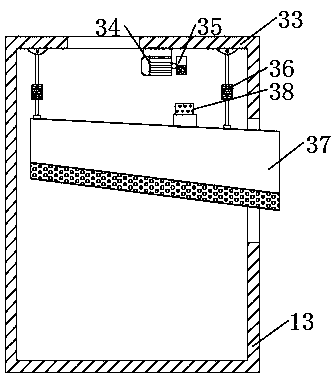

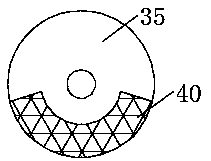

[0019] Such as Figure 1-3 As shown, the present embodiment adopts the following technical solutions: a drying device for the production of calcium hypochlorite, comprising a drying device body 1, the drying device body 1 is composed of a stirring mechanism 2, a drying mechanism 3, a conveying mechanism 4 and Screening mechanism 5 is formed, and the bottom of described stirring mechanism 2 is fixedly connected with drying mechanism 3, and the bottom of described drying mechanism 3 is connected with conveying mechanism 4, and the bottom of described conveying mechanism 4 is provided with screening mechanism 5, and described stirring mechanism 2 It consists of a stirring tank 6, a first heating plate 7, a horizontal stirring shaft 8, a second stirring motor 9, a vertical stirring shaft 10, a first stirring motor 11, a stirring blade 12 and a first feeding port 13. The stirring barrel 6. A vertical stirring shaft 10 is rotatably connected between the top and the bottom of the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com