Humidity elimination control system based on elimination starting temperature and humidity elimination method

A control system, temperature and humidity technology, applied in the field of drying, can solve the problems of the drying process can not be carried out normally, vicious cycle and energy waste, relative humidity can not be effectively reduced, to prevent the temperature can not be effectively increased, to prevent energy loss , Remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

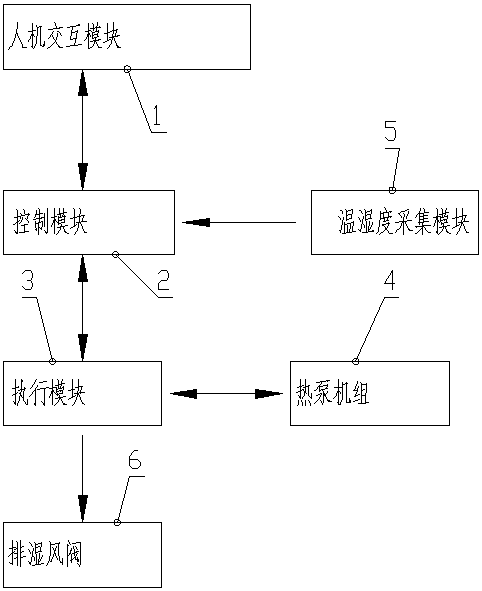

[0040] figure 1 The direction indicated by the middle arrow is the transmission direction of information. Humidity in the present invention refers to relative humidity.

[0041] like figure 1As shown, the dehumidification control system based on the start-up temperature of the present invention includes a drying room, a human-computer interaction module 1 for human-computer interaction, a control module 2, an execution module 3, a heat pump unit 4, a temperature and humidity acquisition module 5 and Humidity exhaust air valve 6; humidity exhaust air valve 6 is installed at the drying room and is used to discharge hot and humid air in the drying room; heat pump unit 4 is used to provide heat energy for the drying room; the drying room is a conventional technology, not shown in the figure Show. The human-computer interaction module 1 includes a display screen and an input device. When the display screen is a touch screen, it has both the functions of a display screen and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com