Active noise reduction range hood and noise reduction method thereof

A technology of active noise reduction and range hood, applied in the fields of oil fume removal, heating methods, household heating, etc., can solve the problems of increasing the difficulty of noise reduction in three-dimensional space, inability to adapt to high-order sound, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

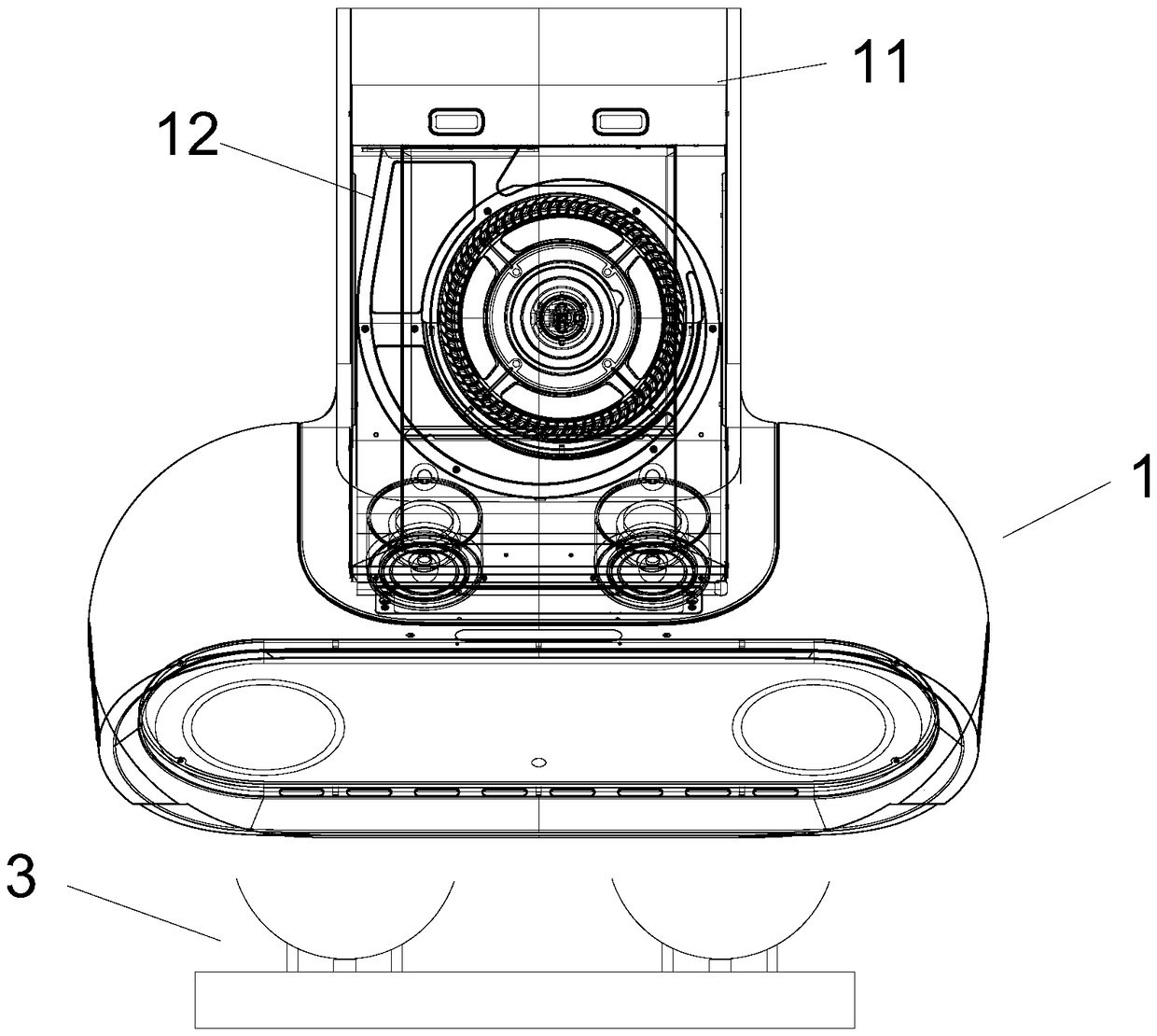

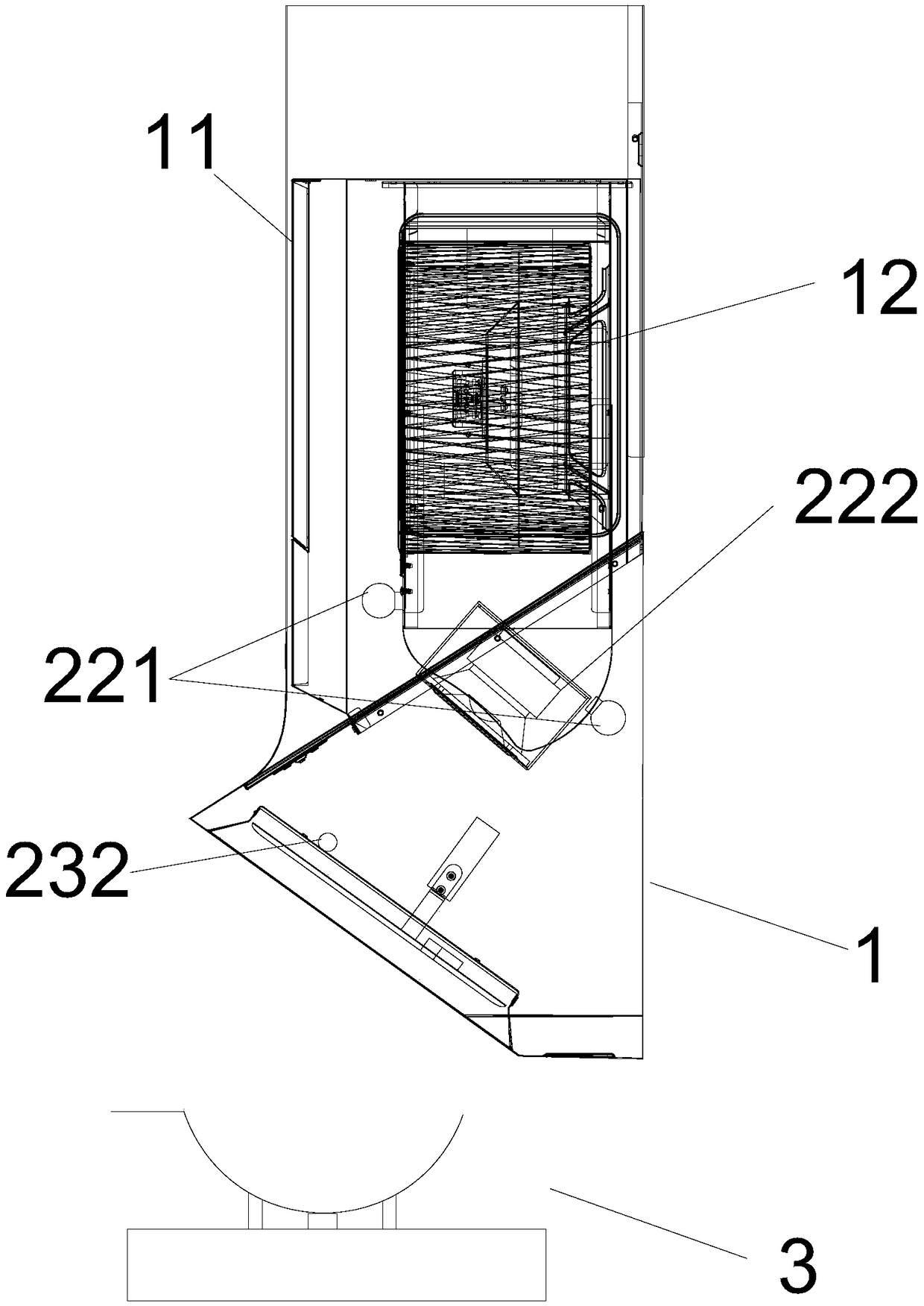

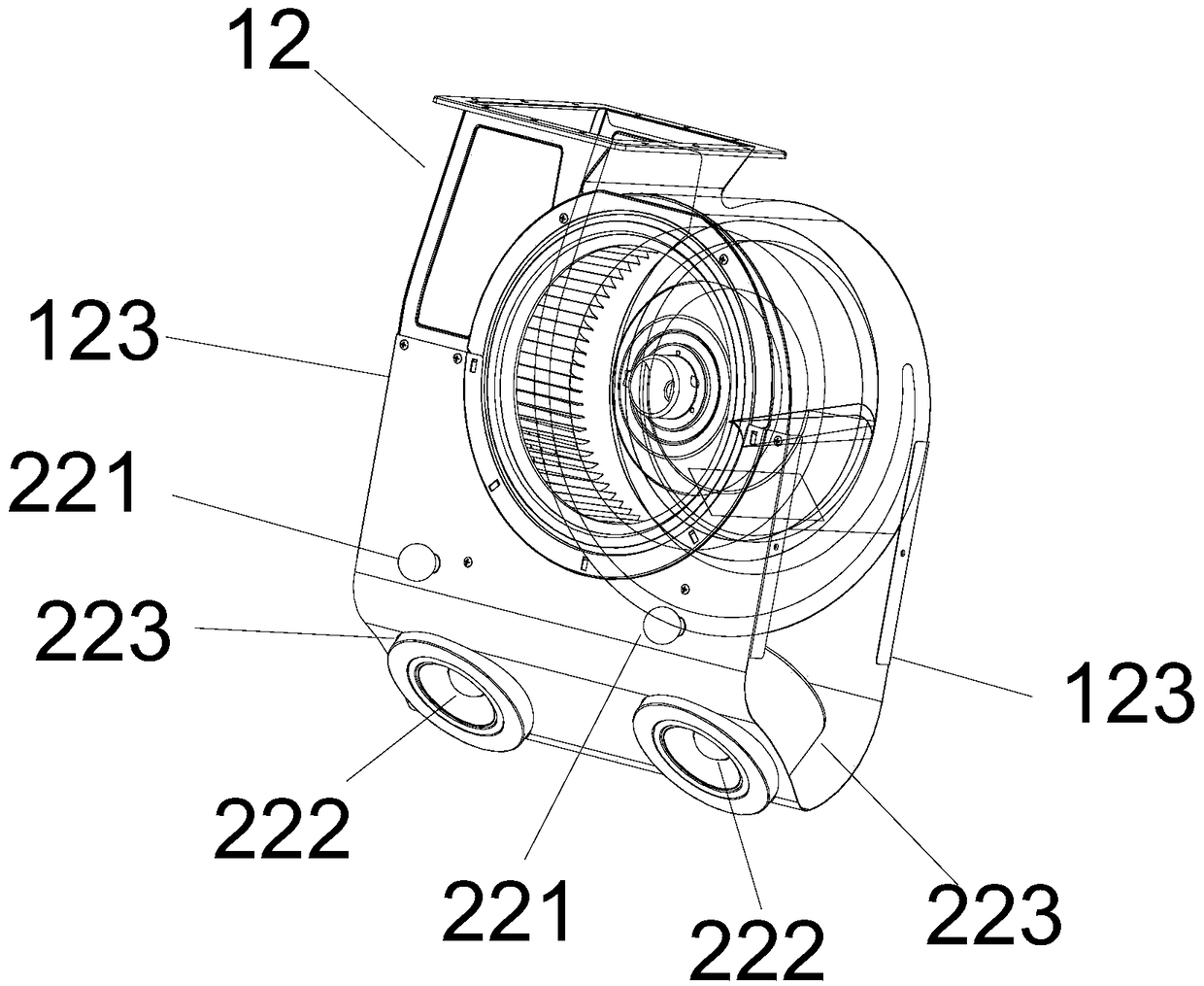

[0093] An active noise reduction range hood, such as Figures 1 to 9 As shown, a hood main body 1 and a three-dimensional sound field noise reduction device 2 for active noise reduction are provided, and the three-dimensional sound field noise reduction device 2 is assembled inside the hood main body 1 .

[0094] The three-dimensional sound field noise reduction device 2 is provided with a three-dimensional sound field noise reduction unit 22 and an adaptive noise reduction control unit 23, the adaptive noise reduction control unit 23 is electrically connected to the three-dimensional sound field noise reduction unit 22, and the three-dimensional sound field noise reduction unit 22 and the adaptive noise reduction control unit 23 are respectively assembled on the main body 1 of the cigarette machine.

[0095] The three-dimensional sound field noise reduction unit 22 is provided with a speaker 222 and an acoustic resonance box 223 , the speaker 222 is installed inside the acous...

Embodiment 2

[0119] An active noise reduction range hood, other features are the same as in Embodiment 1, such as Figure 10 As shown, the difference is that the planes where the acoustic resonance box 223 and the air inlet are located are parallel to each other.

[0120] The acoustic resonance box 223 of this embodiment is parallel to the plane where the air inlet is located. It is verified by a large number of experimental data that the noise reduction effect of this embodiment is better than that of Embodiment 1.

Embodiment 3

[0122] An active noise reduction range hood, other features are the same as in Embodiment 1, the difference is that the outer surface of the low-damping bellows 11 of this embodiment is equipped with a foam board.

[0123] It should be noted that the outer surface of the low-damping bellows 11 of the present invention may be equipped with a foam board, or any one of a foam board or a rubber board.

[0124] The role of the foam board, foam board or rubber board is to block the noise from spreading to the outside, thereby reducing the noise level.

[0125] Compared with Embodiment 1, the noise reduction effect of the range hood of this embodiment is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com