A Highly Reliable Linkage Cylinder

A cylinder and linkage technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of poor reliability, high malfunction rate, complex structure, etc., and achieve high reliability, high sealing reliability, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0040] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

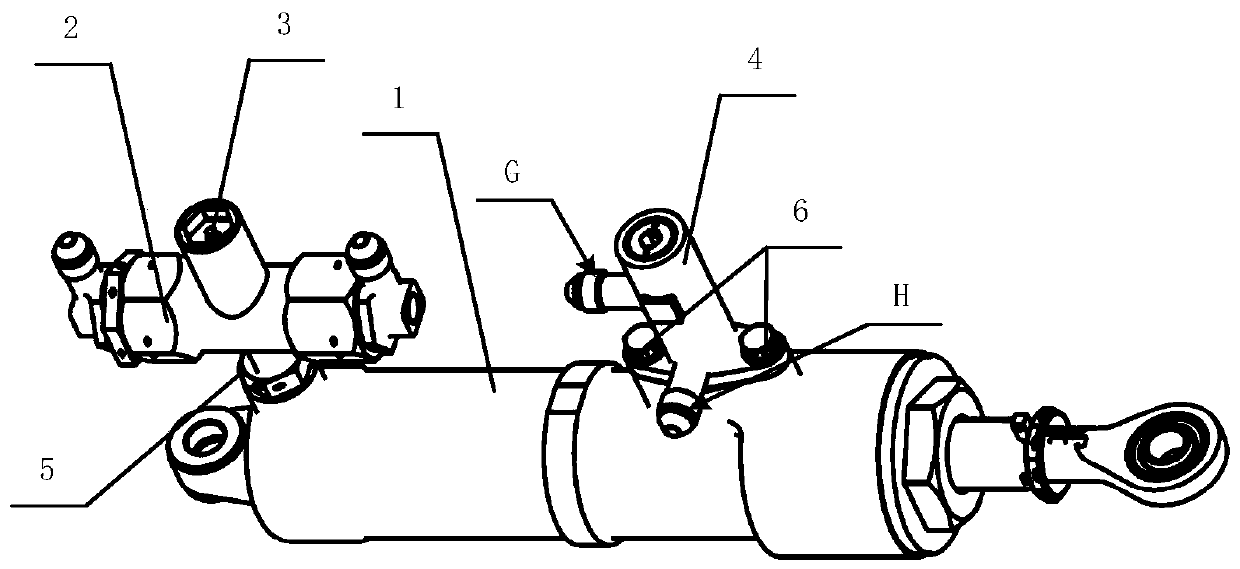

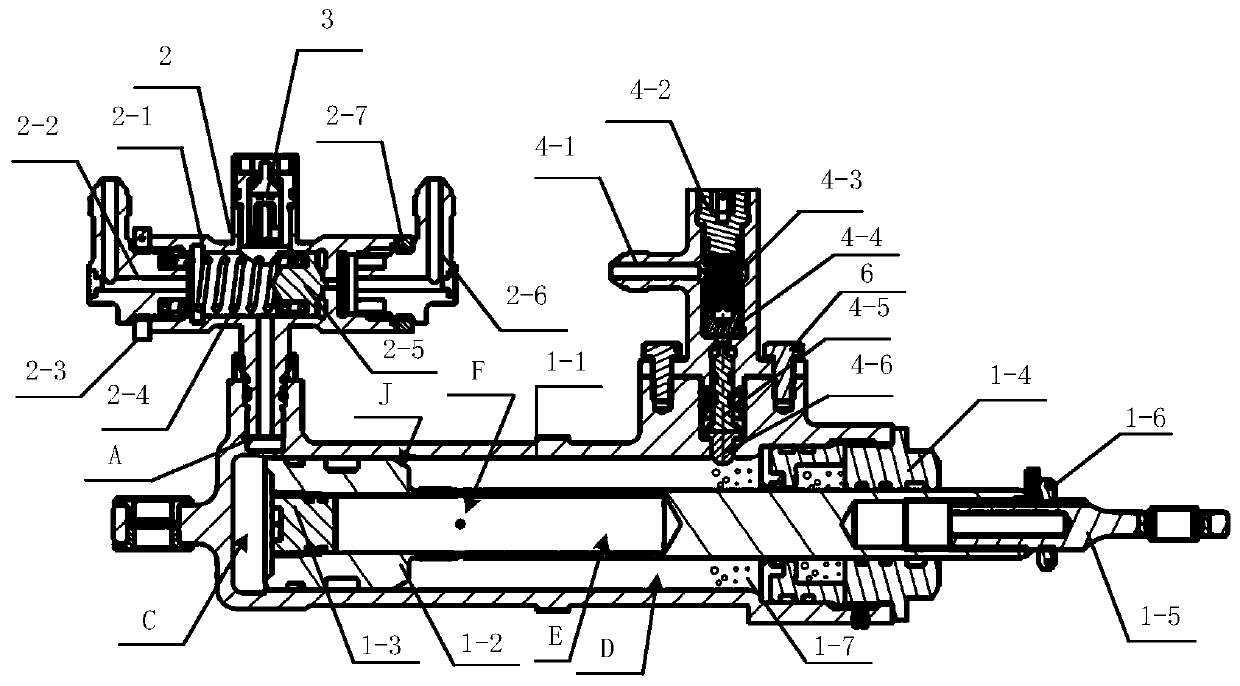

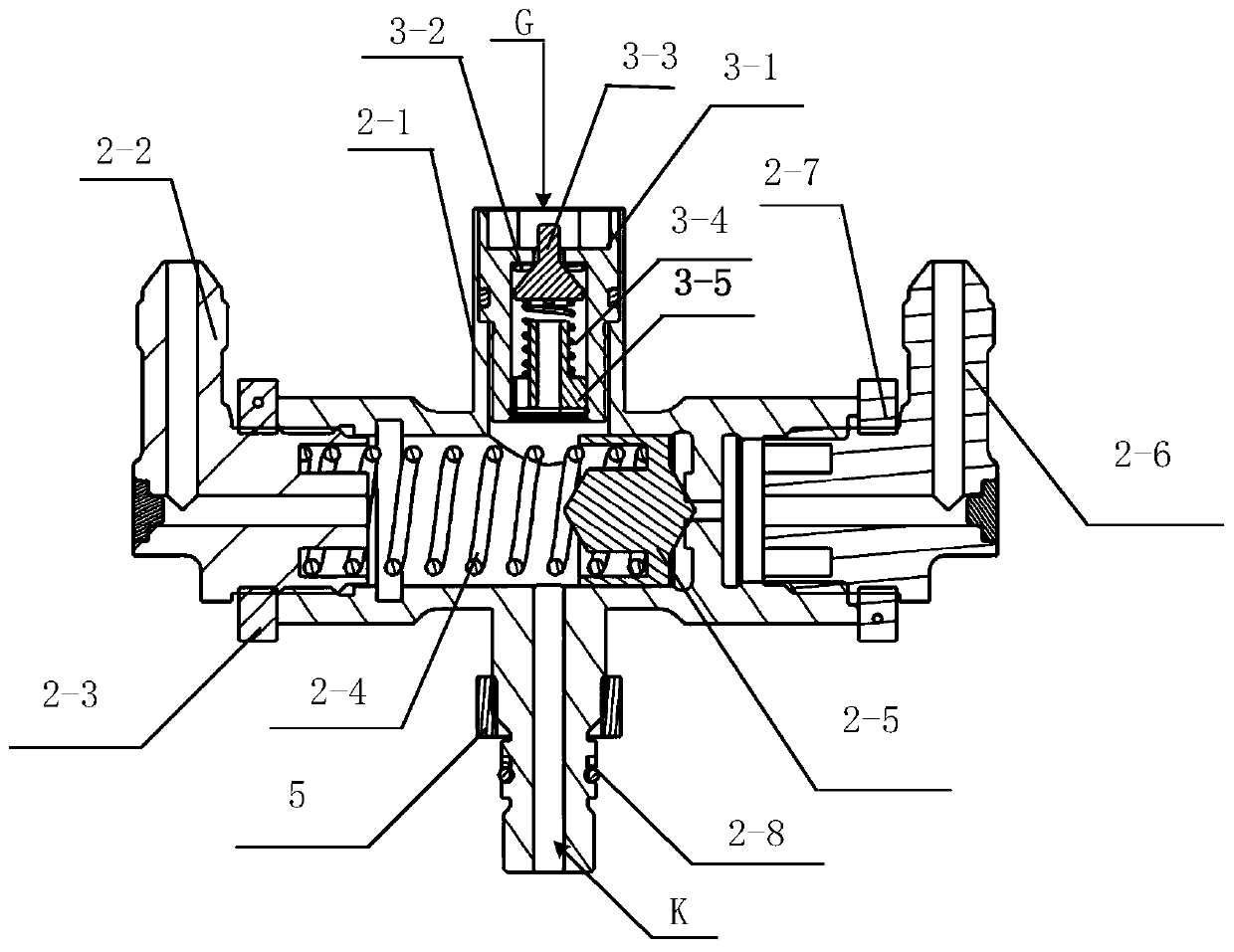

[0041] Such as Figure 1-5 Shown is the outline drawing of the double redundancy and high reliability linkage cylinder of the present invention, from which it can be seen that the double redundancy and high reliability linkage cylinder includes a cylinder main body 1, an intake selection valve 2, an exhaust valve 3 and a linkage valve 4. Wherein the intake valve 2 is connected with the intake port A of the cylinder main body 1 through threaded connection, the axial direction of the intake valve 2 and the cylinder main body 1 can be adjusted, and can be locked by the lock nut 5 after the adjustment is completed. The exhaust valve 3 is installed at the air inlet A to discharge the gas in the rodless cavity C when the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com