Foundation treatment construction method with column hammer dynamic-consolidation replacement effect

A foundation treatment and dynamic compaction replacement technology, which is applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as high cost and environmental pollution, and achieve the effects of saving engineering costs, reducing environmental pollution, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with specific embodiments, but it should be understood that the protection scope of the present invention is not limited by specific embodiments.

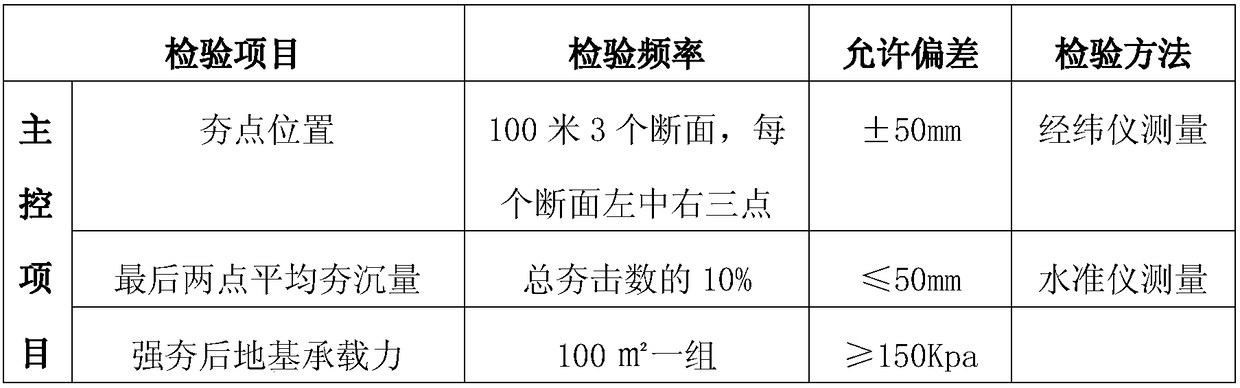

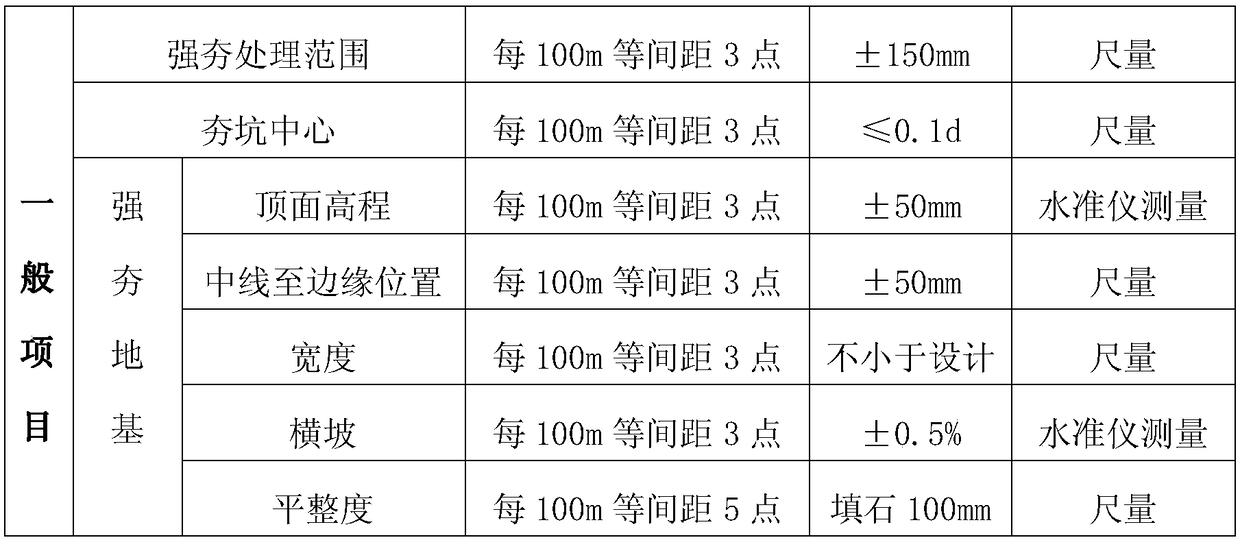

[0033] The embodiment of the present invention provides a foundation treatment construction method for column hammer dynamic tamping replacement. The foundation treatment construction method for column hammer dynamic tamping replacement is to select different replacement materials and dynamic pressure equivalents according to the geological conditions of different projects. The ground is rammed to form holes, and the rammed pit is backfilled with industrial waste aggregates, local waste earth, stone or gravel mixture, and waste construction waste. After repeated ramming and backfilling, the final low-hammer general ramming forms a compact foundation that conforms to the foundation. Replace the pier to achieve the purpose of strengthening the soft soil of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com