Box beam considering external prestressed strengthening and prestressed strengthening method thereof

An external prestressing and prestressing technology, applied in bridge reinforcement, bridges, bridge materials, etc., can solve problems such as excessive deflection of the main span, loss of deflection, secondary construction space, construction quality and construction period cannot be guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

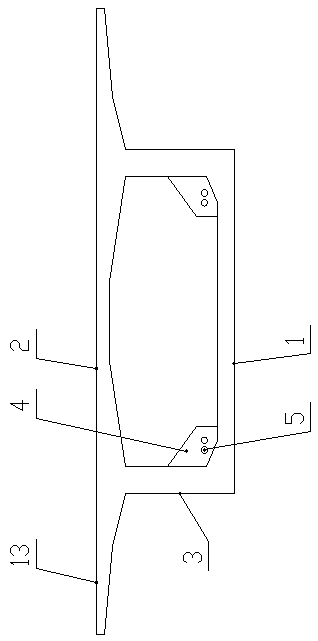

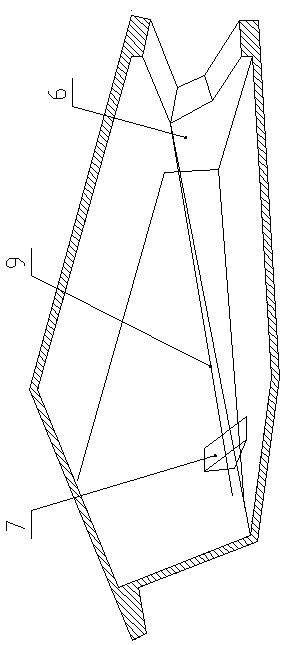

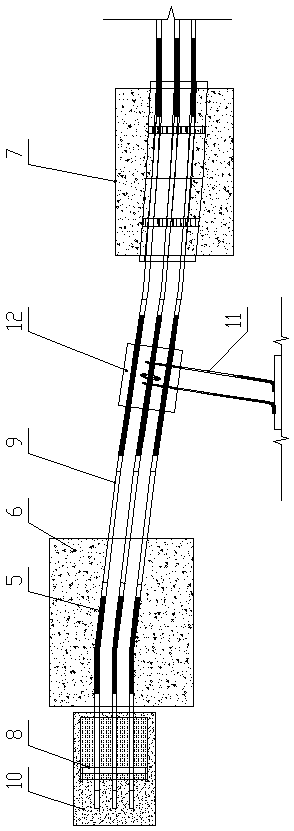

[0030] Such as Figure 1-Figure 4 As shown, the box girder of the present invention considering external prestressing reinforcement includes a bottom plate 1, a top plate 2, a flange plate 13 and two webs 3, which are fixed on the upper surface of the bottom plate 1 and / or the inner side of the webs 3 A number of reinforced concrete blocks 4 are provided, with the length direction of the bottom plate 1 as the front-to-back direction, all the reinforced concrete blocks 4 are arranged at intervals along the front-to-back direction, and several front-to-back transparent bellows 5 are pre-embedded in the reinforced concrete block 4. A reinforced concrete block 4 at the front end and the rear end is an anchor block 6, and the reinforced concrete block 4 between the two anchor blocks 6 is a steering block 7, and all the steering blocks 7 and the corrugated pipes 5 in the two steering blocks 7 are correspondingly worn A prestressed steel strand 9 is provided, and the front side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com