Al+Ti series low-cost high-strength ship plate steel and manufacturing method thereof

A ship plate steel, low-cost technology, applied in low-cost high-strength ship plate steel EH36 and its manufacturing field, can solve the problem of adding more alloy elements, etc., achieve the effects of reducing alloy addition, low alloy cost, and low chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

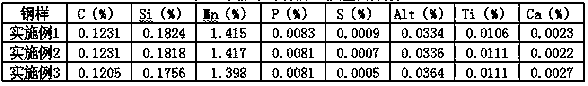

[0021] The present invention is an Al+Ti series low-cost high-strength ship plate steel, the mass percent of its chemical composition is: C: 0.09-0.1%; Si: 0.15-0.25%; Mn: 1.38-1.48%; P: ≤0.01%; S : ≤0.002; Alt: 0.04-0.06%; Ti: 0.008-0.016%; Ca: 0.0015-0.004%; the balance is Fe and unavoidable trace impurity elements.

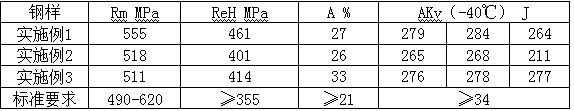

[0022] Further, the yield strength of the high-strength ship plate EH36 is ≥355MPa, the tensile strength is 490-620MPa, and the impact energy at -40°C (transverse direction) is ≥34J; the maximum thickness of the finished ship plate steel is 50mm.

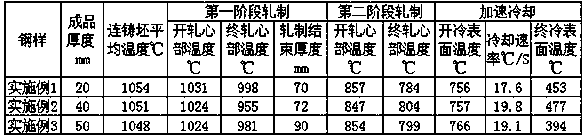

[0023] Its manufacturing method includes the following specific steps: S1: design, smelt and cast according to the composition of the steel grade to form a continuous casting slab; S2: heat the continuous casting slab to an average temperature of 980-1080°C, and keep it warm for ≥ 30 minutes; S3: The continuous casting slab is rolled in two stages, the first stage of rolling is the rough rolling stage, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com