Emulsion paint with water-whitening resistance

A latex paint and performance technology, applied in the field of latex paint, can solve the problems of reducing the surface performance of latex paint film, easy to age and fall off, easy to whiten, etc., and achieve the effect of overcoming rain marks, low cost, and good water-whitening resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

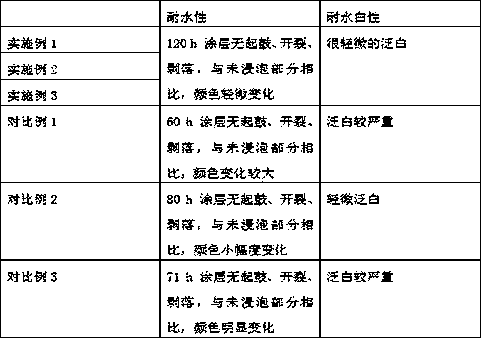

Embodiment 1

[0020] A latex paint with water-whitening resistance, the water-whitening-resistant latex paint contains 5.5-9.8% by mass of 1-hydroxybenzotriazole modified nano-sericite.

[0021] Further, the preparation method of the 1-hydroxybenzotriazole modified nano-sericite is:

[0022] (1) Disperse nano-sericite evenly in deionized water to prepare a nano-sericite dispersion with a mass fraction of 15%;

[0023] (2) Adjust the pH of the nano-sericite dispersion to 3.5-4.0, then add 3.5% of its mass silane coupling agent to the nano-sericite dispersion, heat to 60-70°C, and stir at 2000r / min for 2 hours, Then carry out suction filtration, use deionized water to wash the nano-sericite to neutrality, and dry to constant weight;

[0024] (3) Evenly disperse the nano-sericite after the above treatment into the ethanol solution with a mass fraction of 10% at a ratio of 150g:400mL to obtain a nano-sericite ethanol dispersion, ultrasonically treat it for 2 minutes, and add it to the nano-ser...

Embodiment 2

[0033] A latex paint with water-whitening resistance, the water-whitening-resistant latex paint contains 5.5-9.8% by mass of 1-hydroxybenzotriazole modified nano-sericite.

[0034] Further, the preparation method of the 1-hydroxybenzotriazole modified nano-sericite is:

[0035] (1) Disperse nano-sericite evenly in deionized water to prepare a nano-sericite dispersion with a mass fraction of 15%;

[0036] (2) Adjust the pH of the nano-sericite dispersion to 3.5-4.0, then add 3.5% of its mass silane coupling agent to the nano-sericite dispersion, heat to 60-70°C, and stir at 2000r / min for 2 hours, Then carry out suction filtration, use deionized water to wash the nano-sericite to neutrality, and dry to constant weight;

[0037] (3) Evenly disperse the nano-sericite after the above treatment into the ethanol solution with a mass fraction of 10% at a ratio of 150g:400mL to obtain a nano-sericite ethanol dispersion, ultrasonically treat it for 2 minutes, and add it to the nano-ser...

Embodiment 3

[0046] A latex paint with water-whitening resistance, the water-whitening-resistant latex paint contains 5.5-9.8% by mass of 1-hydroxybenzotriazole modified nano-sericite.

[0047] Further, the preparation method of the 1-hydroxybenzotriazole modified nano-sericite is:

[0048] (1) Disperse nano-sericite evenly in deionized water to prepare a nano-sericite dispersion with a mass fraction of 15%;

[0049] (2) Adjust the pH of the nano-sericite dispersion to 3.5-4.0, then add 3.5% of its mass silane coupling agent to the nano-sericite dispersion, heat to 60-70°C, and stir at 2000r / min for 2 hours, Then carry out suction filtration, use deionized water to wash the nano-sericite to neutrality, and dry to constant weight;

[0050](3) Evenly disperse the nano-sericite after the above treatment into the ethanol solution with a mass fraction of 10% in the ratio of 150g: 400mL to obtain a nano-sericite ethanol dispersion, ultrasonically treat it for 2min, and add it to the nano-serici...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com