Mass concrete and preparation and construction process thereof

A large-volume concrete and coagulant technology, which is applied in the direction of construction and building construction, can solve the problems of cracks and undisclosed large-volume concrete, and achieve the effect of reducing cracks, increasing heat dissipation, and improving the peak hydration period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

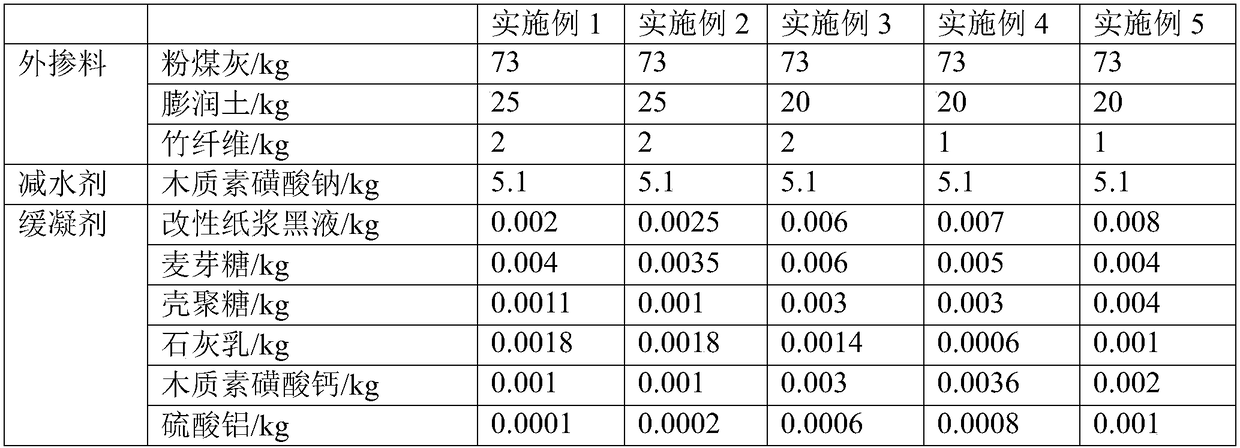

[0056] Mass concrete includes the following weight components: 170kg of water, 180kg of cement, 730kg of medium sand, 1000kg of gravel with a particle size of 5-25mm, 100kg of external admixtures, 175kg of mineral powder, and 5.11kg of admixtures; admixtures include water reducers And retarder; water reducer is 5.1kg of sodium lignosulfonate.

[0057] The external admixture specifically includes fly ash, bentonite and bamboo fiber. Concrete fly ash is 73kg, bentonite is 25kg, and bamboo fiber is 2kg.

[0058] The retarder includes 0.002kg of modified pulp black liquor, 0.004kg of maltose, 0.0011kg of chitosan, 0.0018kg of milk of lime, 0.001kg of calcium lignosulfonate, and 0.0001kg of aluminum sulfate.

[0059] Modified pulp black liquor includes the following treatment process: use sulfuric acid to adjust the pH to 10, add 0.002g of ferric chloride and 0.4g of sodium sulfite in pulp black liquor, keep the temperature at 80°C for 2 hours, and then neutralize with sulfuric ac...

Embodiment 2

[0071] The difference between the second embodiment and the first embodiment lies in the different contents of the concrete components, the different parameters in the modified pulp black liquor, concrete processing and construction technology.

[0072] See Table 1 and Table 2 for components.

[0073] Modified pulp black liquor includes the following treatment process: use sulfuric acid to adjust the pH to 10, add 0.0025g of ferric chloride and 0.5g of sodium sulfite to pulp black liquor, keep the temperature at 80°C for 3 hours, and then neutralize with sulfuric acid to The pH is 8.

[0074] The preparation method of mass concrete comprises the following preparation steps,

[0075] Step 1: Weigh each component of the mass concrete according to parts by weight, and set aside;

[0076] Step 2: Add cement, medium sand, crushed stone, external admixture, mineral powder and water into the mixer and stir for 2 minutes, mix well;

[0077] Step 3: Continue to add the admixture to ...

Embodiment 3

[0084] The difference between the third embodiment and the first embodiment lies in the different contents of the concrete components, the different parameters in the modified pulp black liquor, concrete processing and construction technology.

[0085] See Table 1 and Table 2 for components.

[0086] Modified pulp black liquor includes the following treatment process: use sulfuric acid to adjust the pH to 11, add 0.006g of ferric chloride and 0.12g of sodium sulfite in pulp black liquor, keep the temperature at 85°C for 4 hours, and then neutralize with sulfuric acid to The pH is 9.

[0087] The preparation method of mass concrete comprises the following preparation steps,

[0088] Step 1: Weigh each component of the mass concrete according to parts by weight, and set aside;

[0089] Step 2: Add cement, medium sand, crushed stone, external admixture, mineral powder and water into the mixer and stir for 3 minutes, mix well;

[0090] Step 3: Continue to add the admixture to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com