Glass substrate non-contact air flotation transport device

A non-contact, glass substrate technology, applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of easy friction, etc., to achieve the effect of less pollution or damage, less disturbance, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

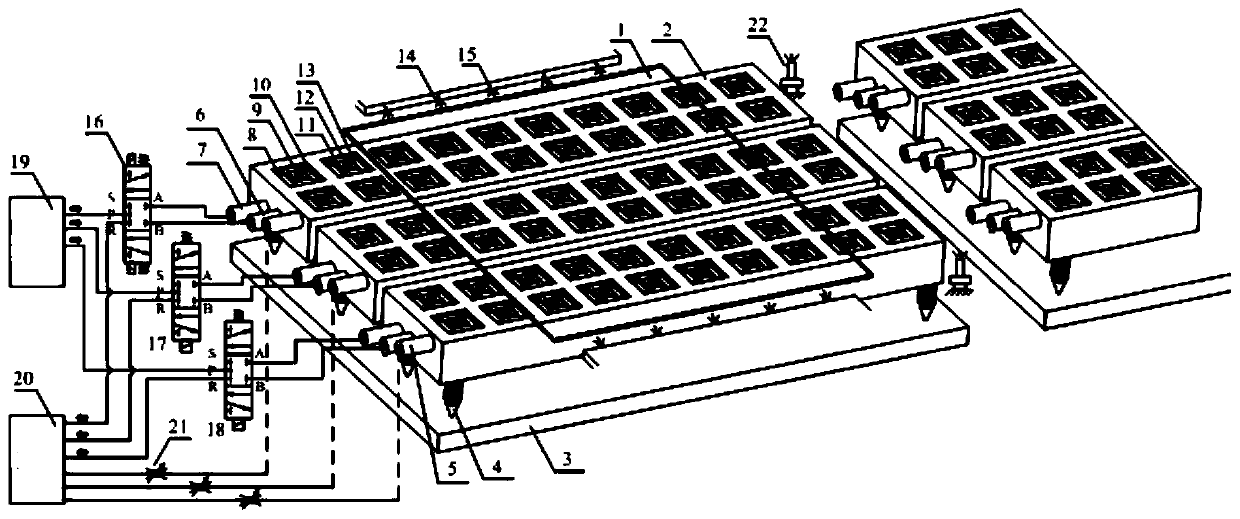

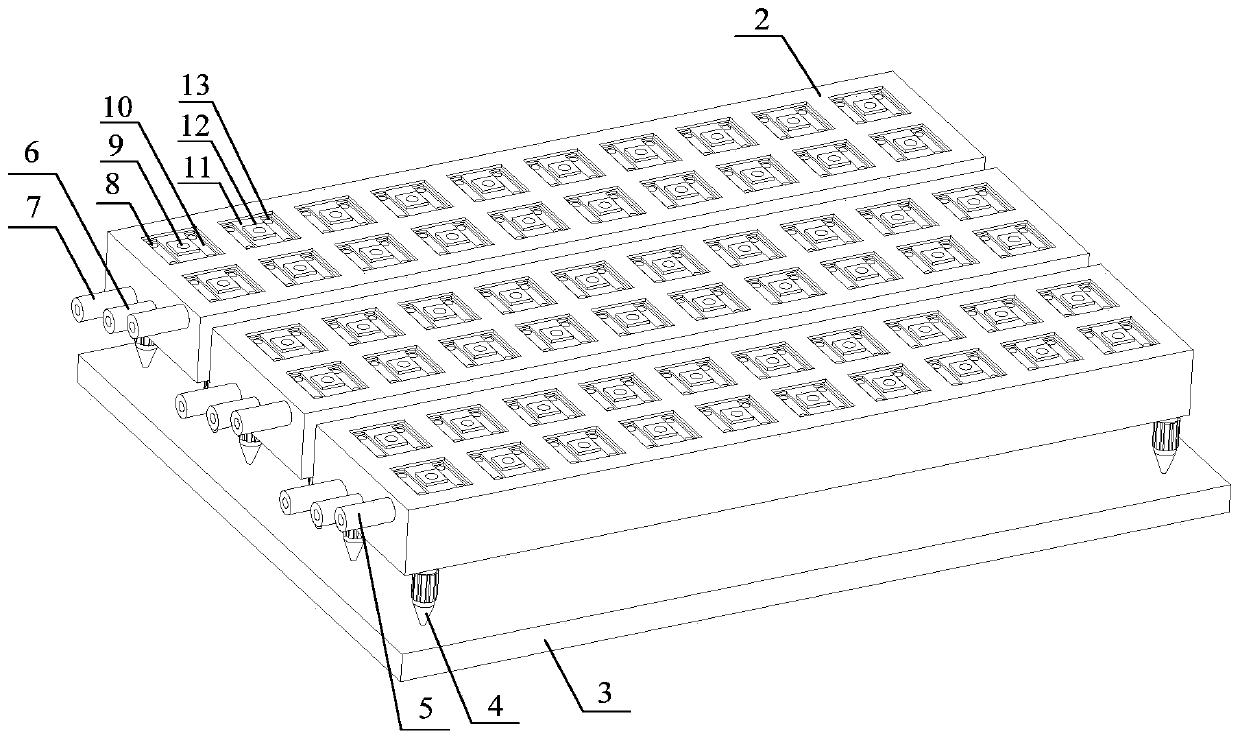

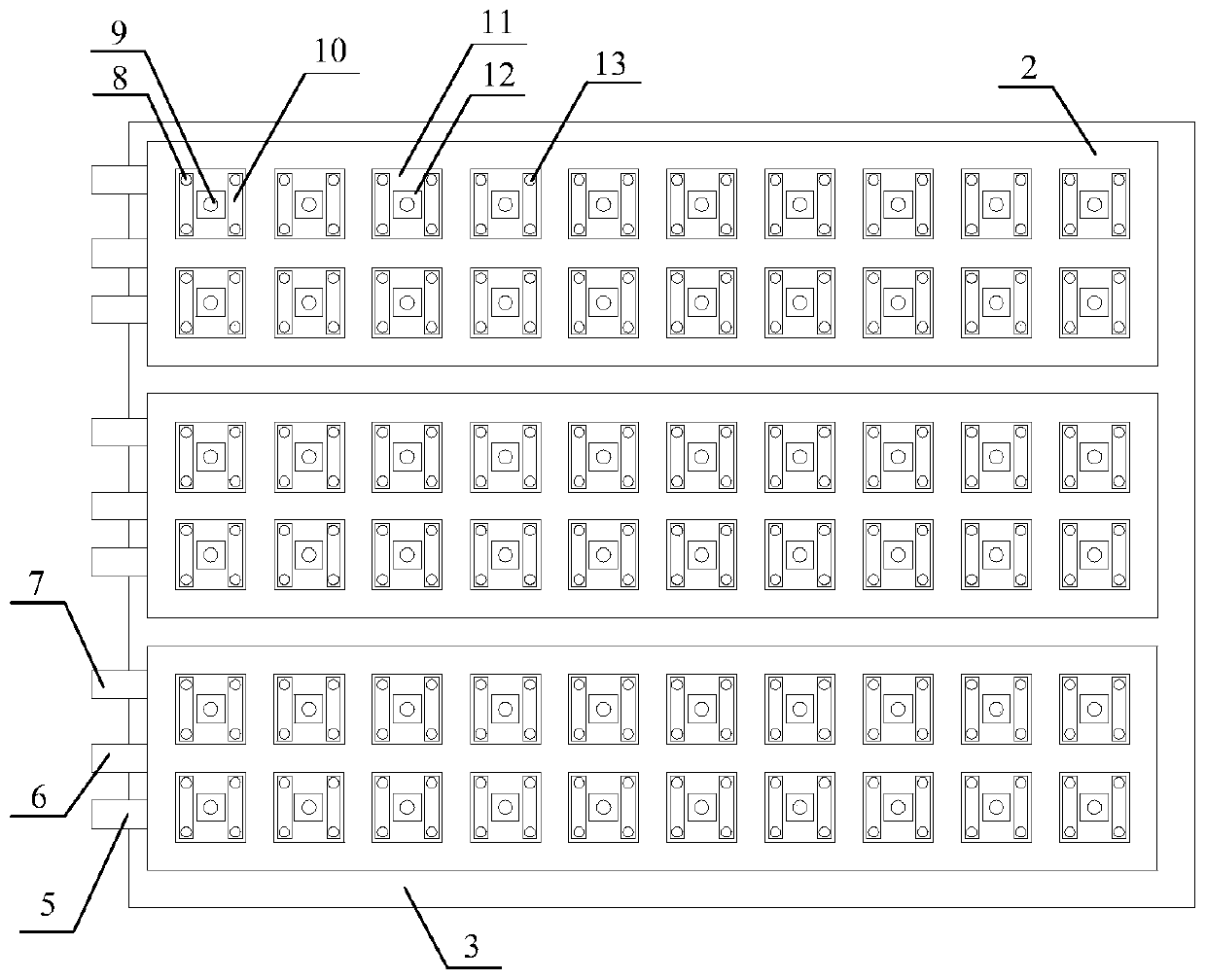

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as Figure 1-4 As shown, a non-contact air flotation transport device for glass substrates includes a base 3 on which an air flotation guide rail 2 is connected via a leveling screw 4 to realize level adjustment of the platform, and the air flotation guide rail 2 is The array is provided with several grooves 11, the cross-section of the grooves 11 is square or rectangular, the depth of the grooves 11 is greater than 100 microns and less than 300 microns, and there are four vent holes of the same size symmetrically distributed inside the grooves 11, Two of them are air inlet holes 8, and the remaining two are air outlet holes 13. Both sides of each groove 11 are provided with a pressure equalizing groove 10, and the air inlet 8 and the air outlet 13 are arranged in the pressure equalizing groove 10. The width of the pressure equalizing groove 10 is slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com