Environmental processing equipment for compound cloth

A technology of processing equipment and composite fabrics, applied in the directions of lamination device, lamination auxiliary operation, lamination, etc., can solve problems such as unfavorable cost savings, achieve the effect of guaranteed quality, simplified operation steps, and reduced operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The content of the present invention will be described below in conjunction with specific embodiments.

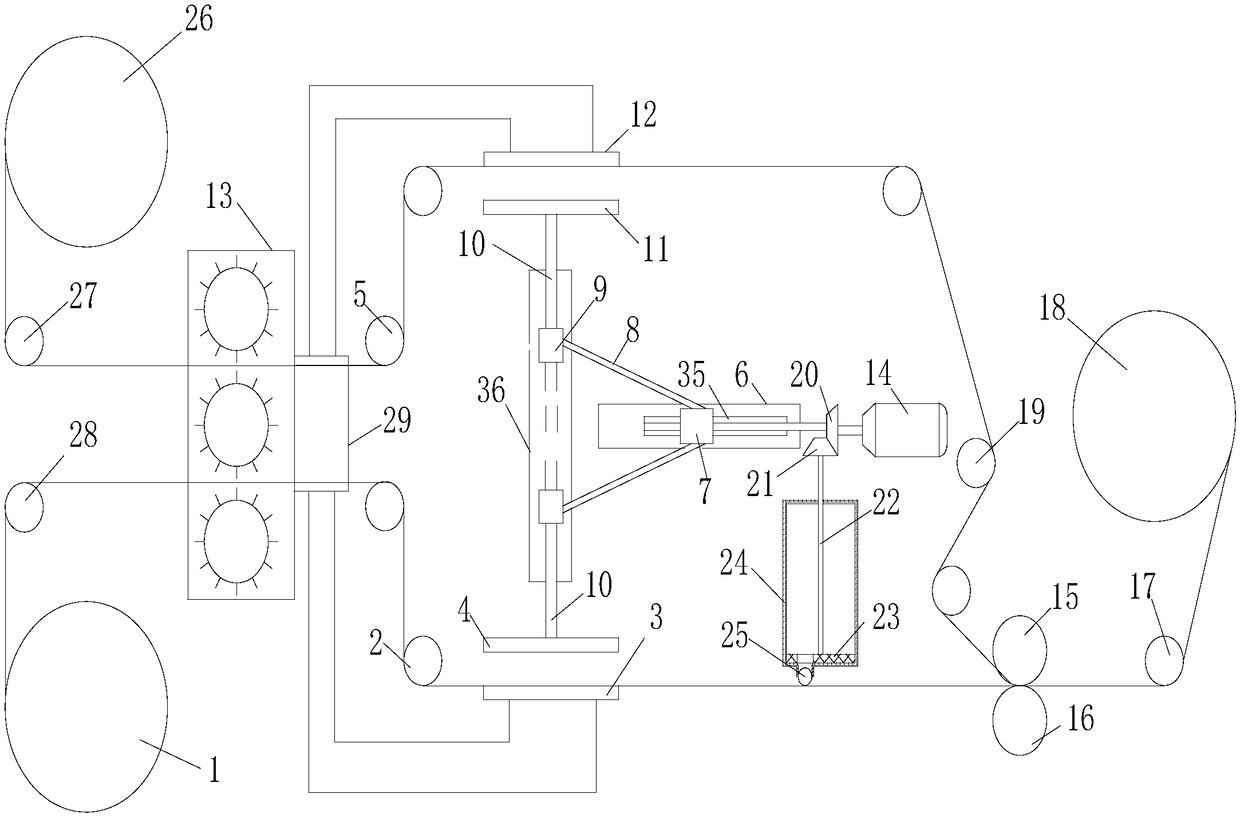

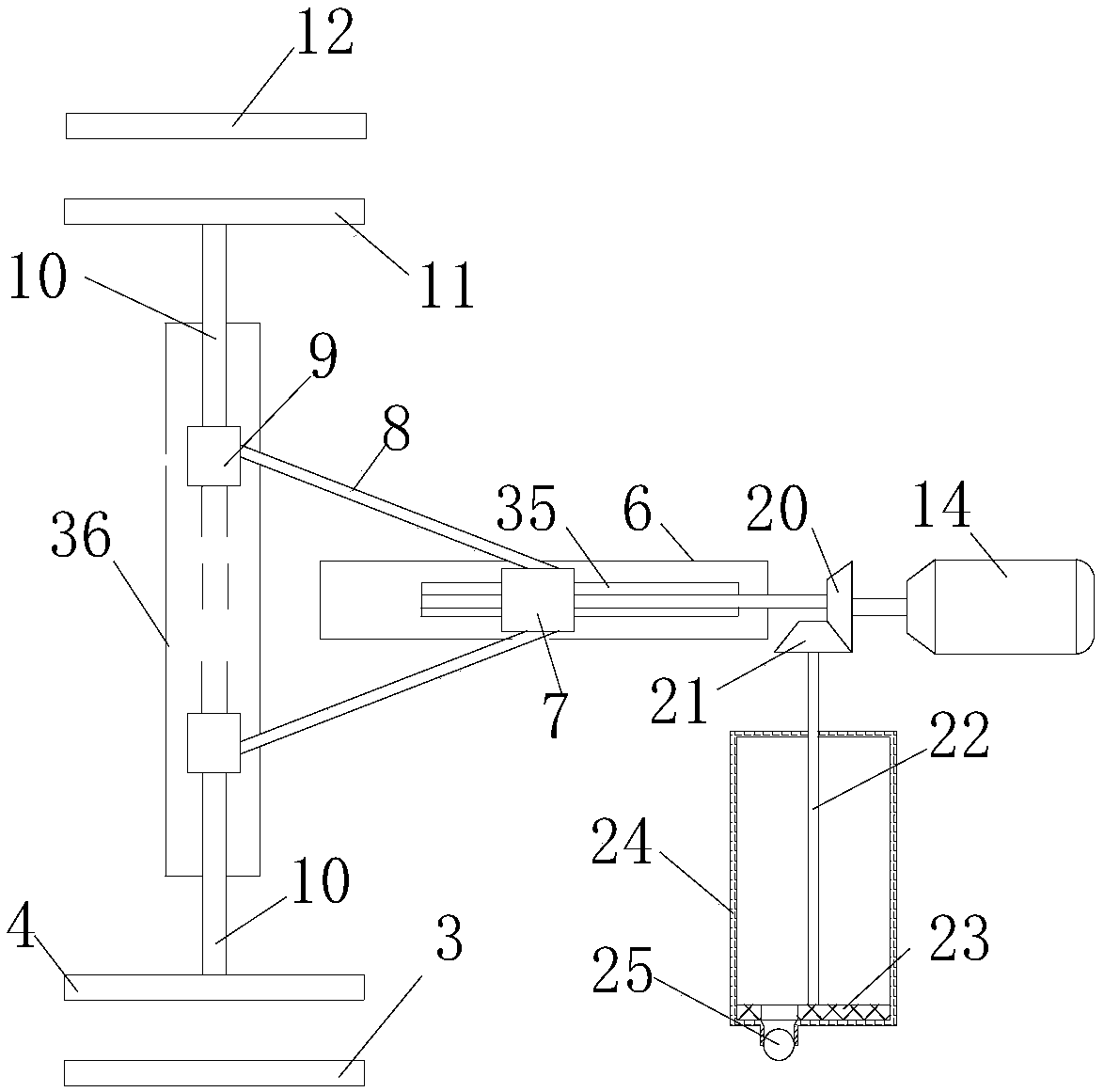

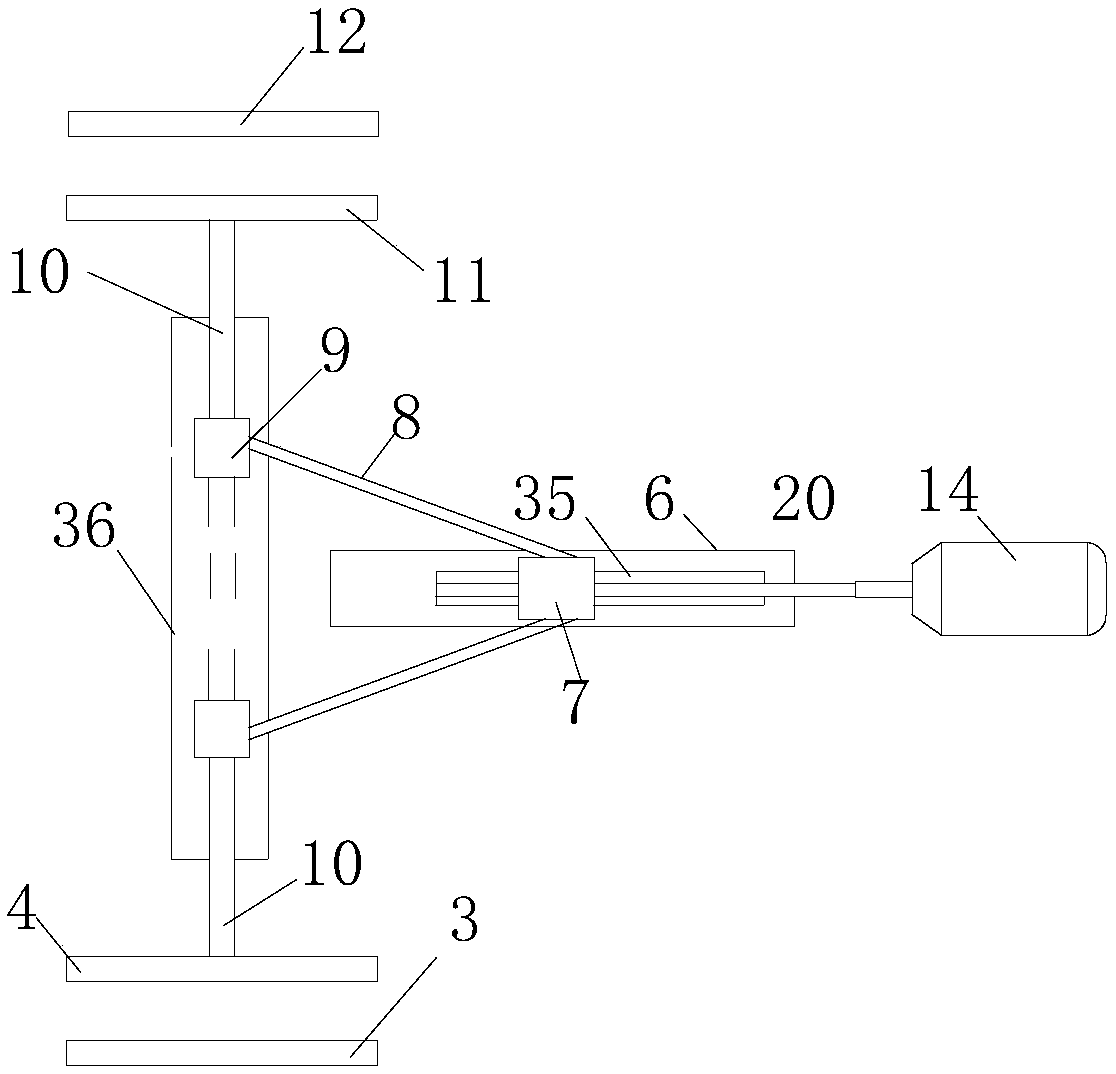

[0038] refer to figure 1 , a composite cloth environmental protection processing equipment proposed by the present invention, the equipment includes a base cloth roll 1 wound with a base cloth, a fabric roll 26 wound with a fabric, a dust removal unit, a leveling unit, a gluing unit, and a pressing roller unit And take-up roller 18.

[0039] The base cloth is output by the base cloth roller 1, and the fabric is output by the fabric roll 26. The dust removal unit is used to remove dust from the base cloth and the fabric. After the dust removal treatment, the base cloth and the fabric can be leveled. into the leveling unit.

[0040] Described dedusting unit comprises casing, and described casing has dedusting chamber 13 and steam chamber 29, and described dedusting chamber 13 and steam chamber 29 are all provided with the inlet and outlet that pass through for base mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com