Dustproof cover used for building engineering stirring machine

A kind of technology of construction engineering and mixer, which is applied in the direction of construction, building structure, cement mixing device, etc., and can solve the problems of atmospheric dust pollution and damage to the breathing environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

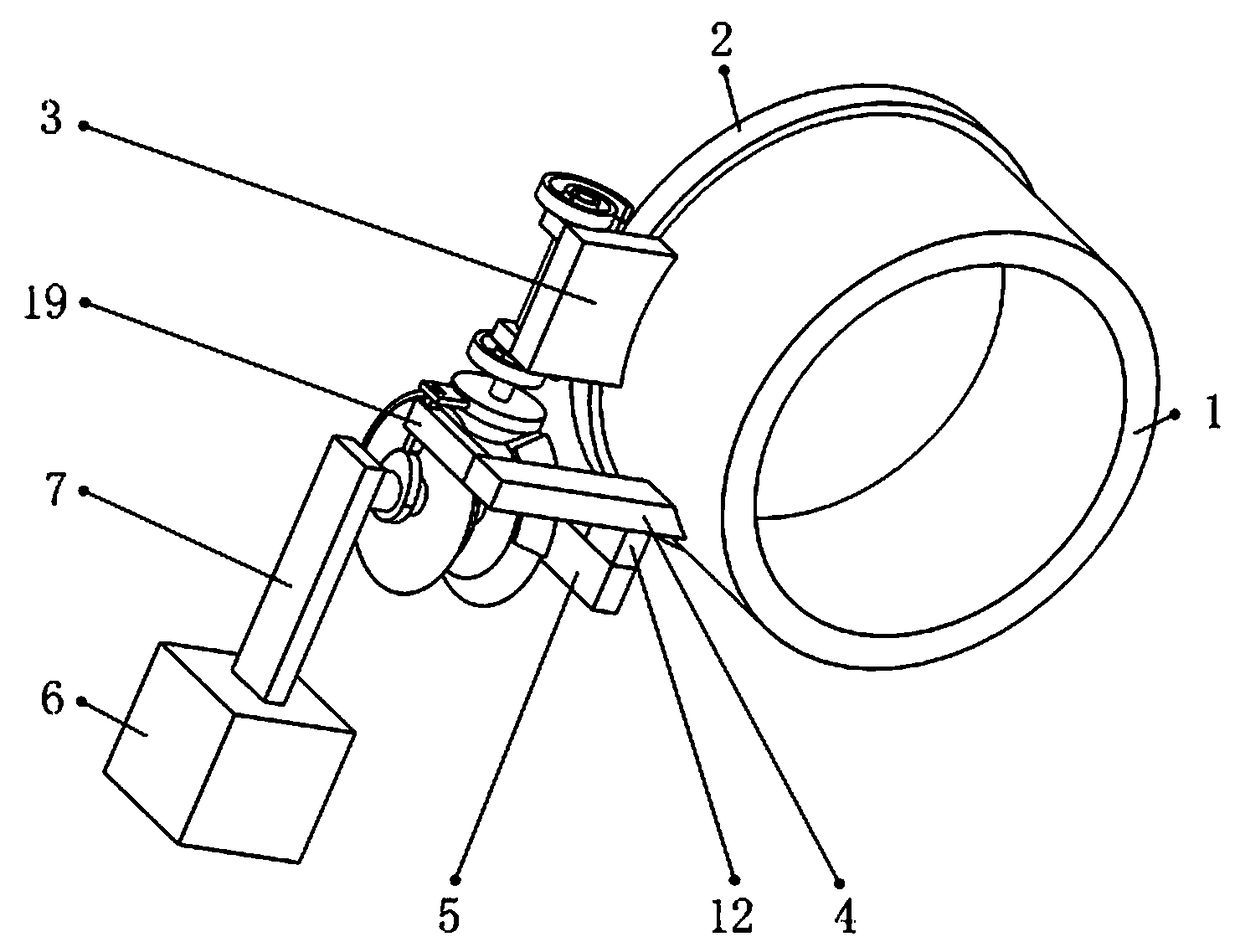

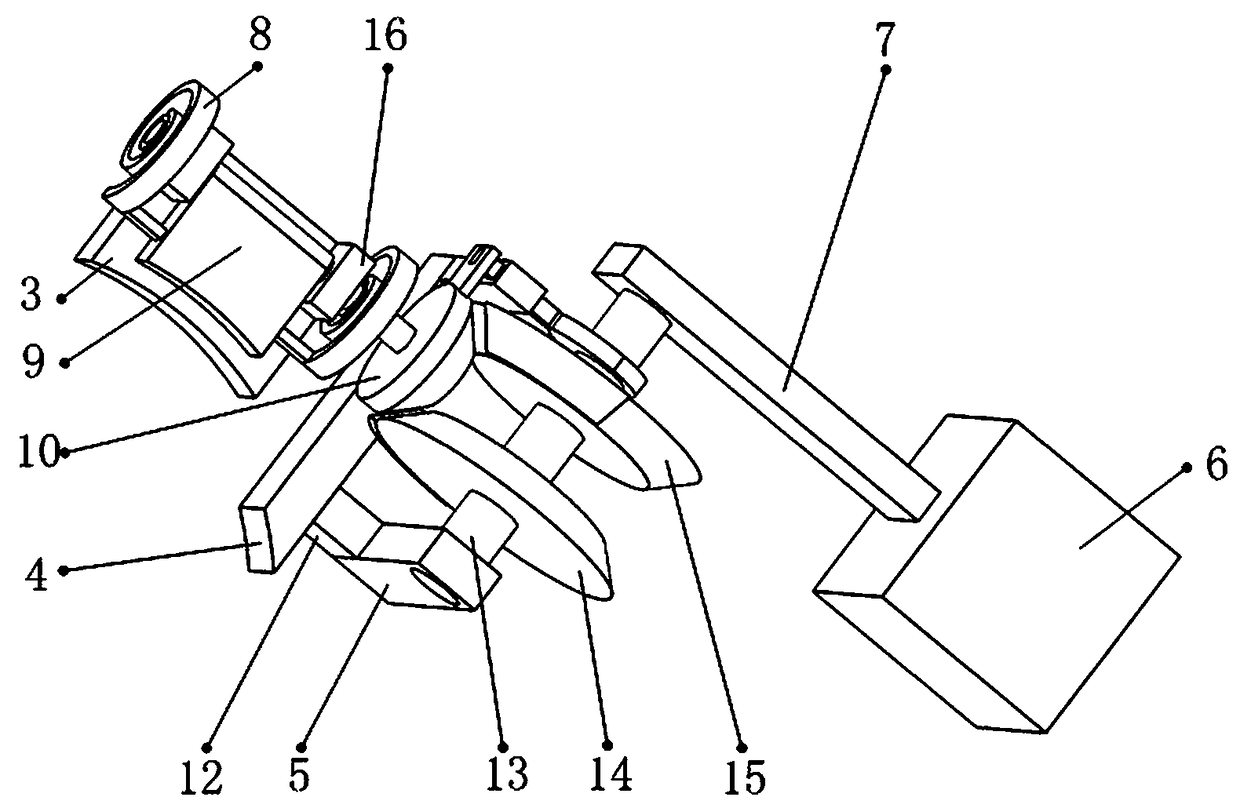

[0067] Specific embodiments: the dust cover in the present invention is mainly suitable for the concrete mixer whose mixing drum is fixed and does not rotate during the mixing process of concrete raw materials, and when the mixing drum of this type of concrete mixer is feeding and discharging, the rotating mechanism makes the mixing When the material inlet and outlet 45 of the drum is facing upwards, the concrete raw materials are received, and when the inlet and outlet 45 of the mixing drum is facing downwards, the stirred concrete is discharged through the rotating mechanism, and when the mixing mechanism is stirring the raw materials of the concrete in the mixing drum, the rotating The mechanism makes the material inlet and outlet 45 of the mixing drum in a horizontal state.

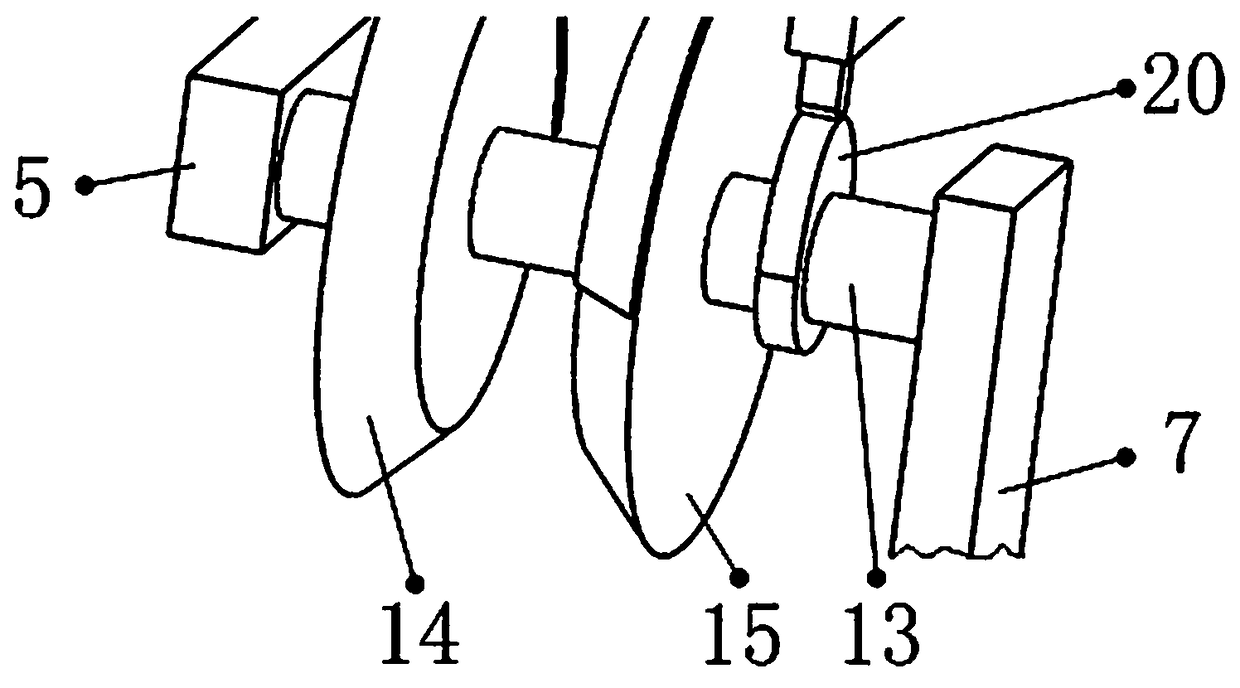

[0068] Such as Figure 14 , 15 As shown, the installation method for the dust cover in the present invention is as follows: the end of the cover 1 in the dust cover away from the cover 2 is nested at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com