Improved sine acceleration cam locking mechanism

A technology of sinusoidal acceleration and cam, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as complex processing, unfavorable self-reconfiguration of cell robots, poor interchangeability of active and passive connection surfaces, etc., to ensure reliability and impact low force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

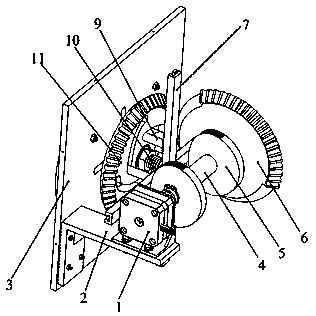

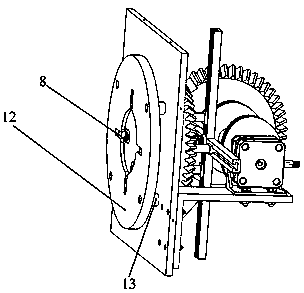

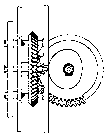

[0015] The structural composition of the present invention is as figure 1 , figure 2 with image 3 shown. The improved sinusoidal acceleration cam locking mechanism consists of servo motor (1), L-shaped plate (2), support plate (3), transmission shaft (4), cam (5), incomplete bevel gear (6), cross guide rail ( 7), slide block (8), guide rail strut (9), spring (10), groove bevel gear (11), connection surface (12), boss (13). The servo motor (1) is connected with the support plate (3) by means of the L-shaped plate (2), and serves as the source power device of the locking mechanism. The transmission shaft (4) is connected with the servo motor (1), and the cam (5) and the incomplete bevel gear (6) are coaxially installed. By changing the power phase sequence of the servo motor (1), the connection between the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com