Wood polishing device

A wood and positioning cylinder technology, applied in the direction of grinding machines, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of labor-intensive, high manual proficiency, etc., to ensure accuracy and increase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

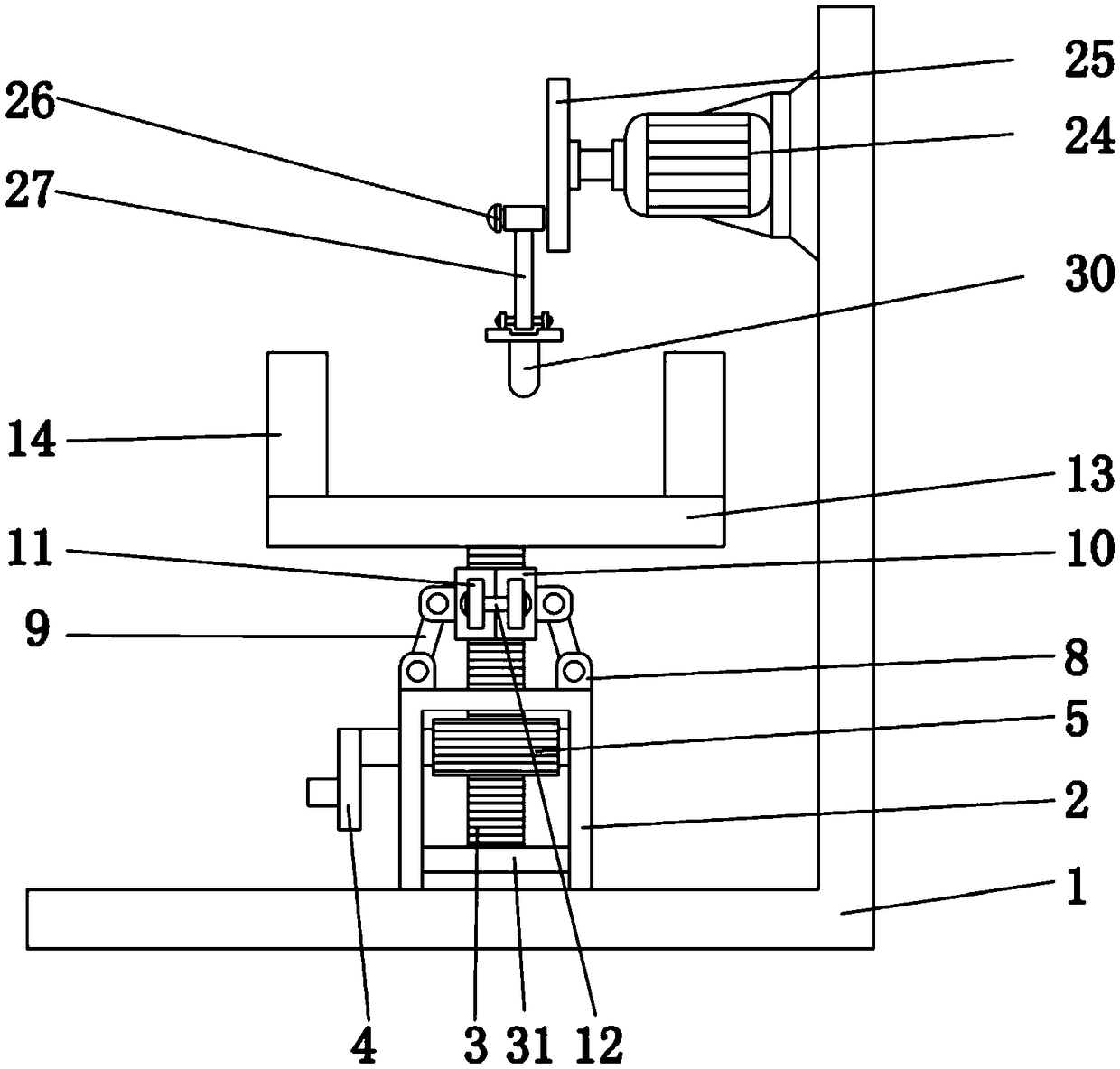

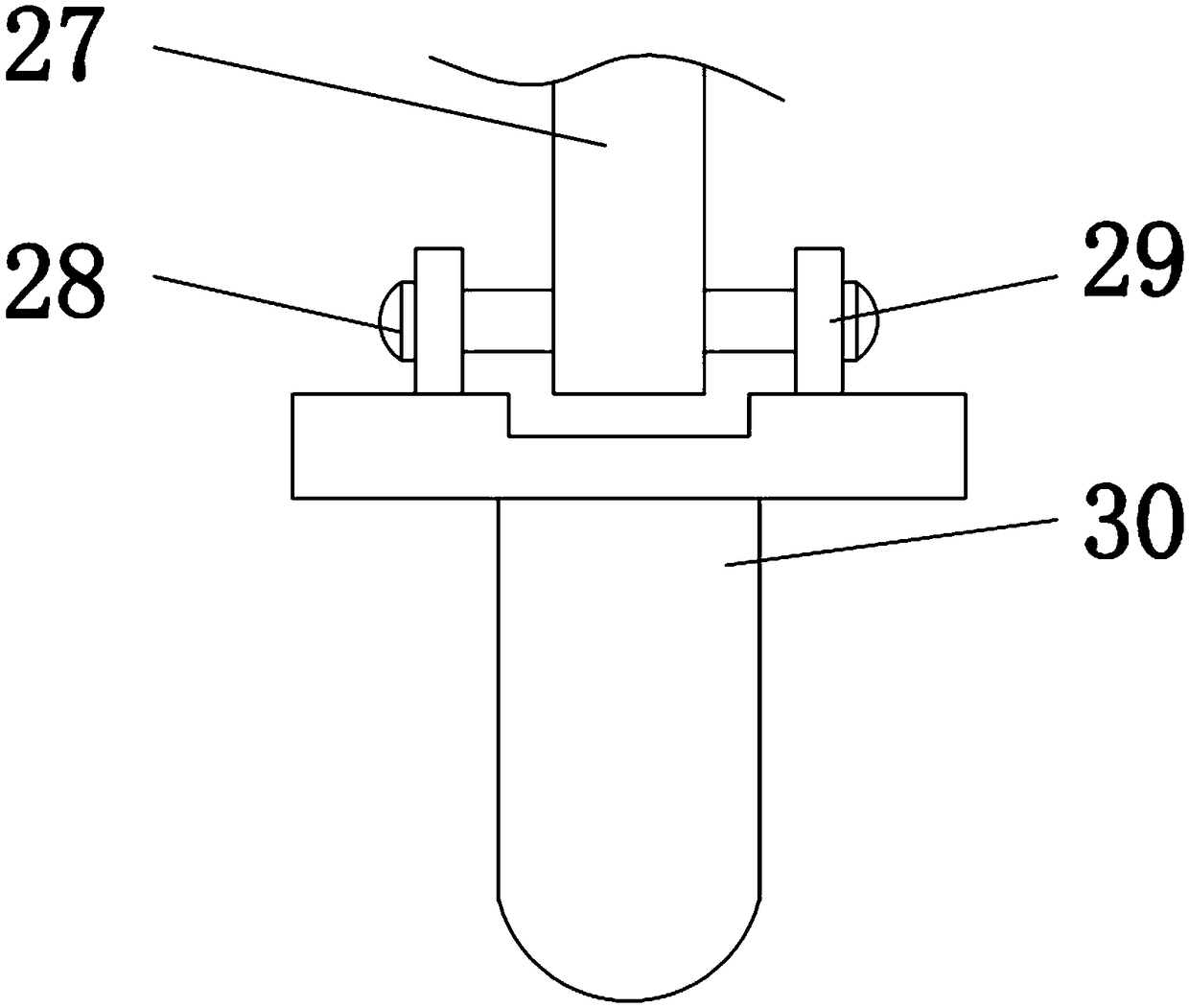

[0036] Embodiment one please refer to figure 1 , 2, a wood grinding device, comprising a frame 1, characterized in that: the frame 1 is fixedly connected with a positioning cylinder 2, the middle part of the positioning cylinder 2 is movably socketed with a rack 3, and the rack 3 One end is fixedly connected with a support plate 13 located above the positioning cylinder 2, the other end of the rack 3 penetrates and extends to the inside of the positioning cylinder 2, and is fixedly connected with a fixed block 31 located inside the positioning cylinder 2, the fixed block 31 The two sides of the two sides are slidingly connected with the inner wall of the positioning cylinder 2, and the side of the positioning cylinder 2 is provided with a rocker 4, and one end of the rocker 4 penetrates and extends to the inside of the positioning cylinder 2, and is connected with the rolling motion inside the positioning cylinder 2. The gear 5 is fixedly connected, and the external teeth of ...

Embodiment 2

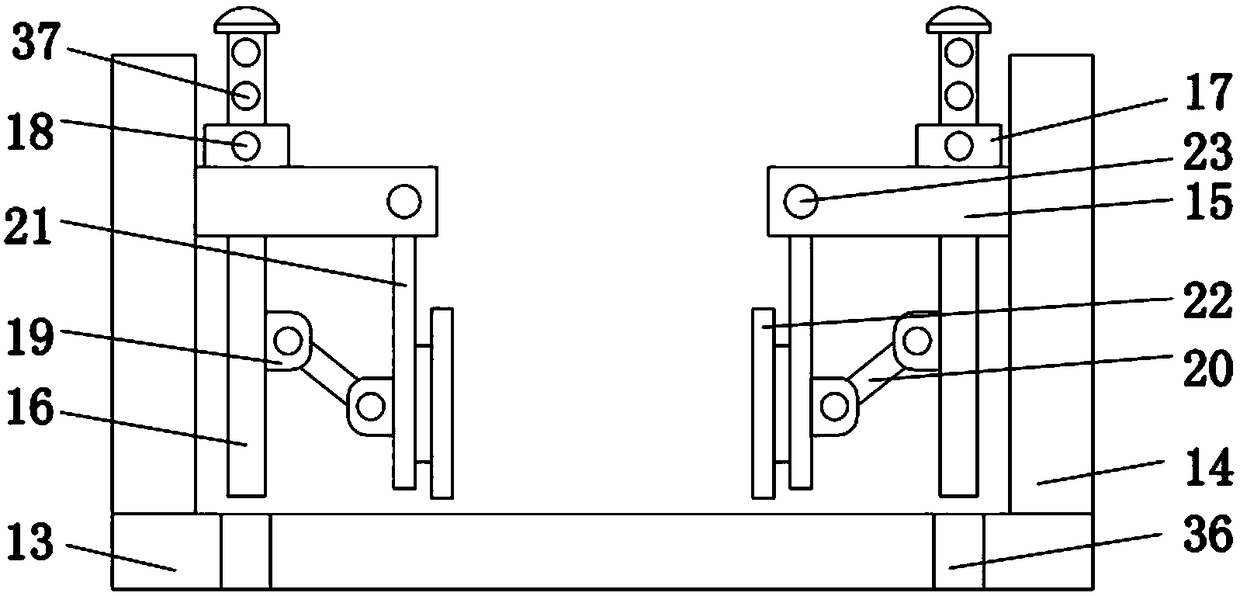

[0037] Embodiment 2 Please refer to image 3 , the opposite surfaces of the two support frames 14 are respectively fixedly connected with a support block 15 located above the support plate 13, and the support block 15 is movably connected with a support rod 16, and one end of the support rod 16 runs through the support block 15, so The top of the supporting block 15 is fixedly connected with a sliding block 17, the sliding block 17 is slidably connected with a sliding rod 18, the supporting rod 16 is provided with a limit hole 37, and one end of the sliding rod 18 runs through the sliding block 17 and the supporting The limit hole 37 on the rod 16, the support block 15 is movably connected with the push rod 21, the support rod 16 and the push rod 21 are respectively fixedly connected with the sliding plate 19, and the two sliding plates 19 are respectively connected with the two ends of the push plate 20 in rotation, A limit clip 22 is connected to the side of the push rod 21 ...

Embodiment 3

[0038] Embodiment three please refer to image 3 The support plate 13 is provided with a slot 36 located below the support rod 16, the section diameter of the slot 36 is larger than that of the support bar 16, and the inner wall of the slot 36 is inserted into the outer surface of the support bar 16. catch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com