A wire crimping piece bending machine

A wire crimping and bending machine technology, which is applied in the field of bending machines, can solve problems such as direct winding, reverse wire crimping of electric energy meter voltage wires, and failure to put them into the jaws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the present invention, the specific implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

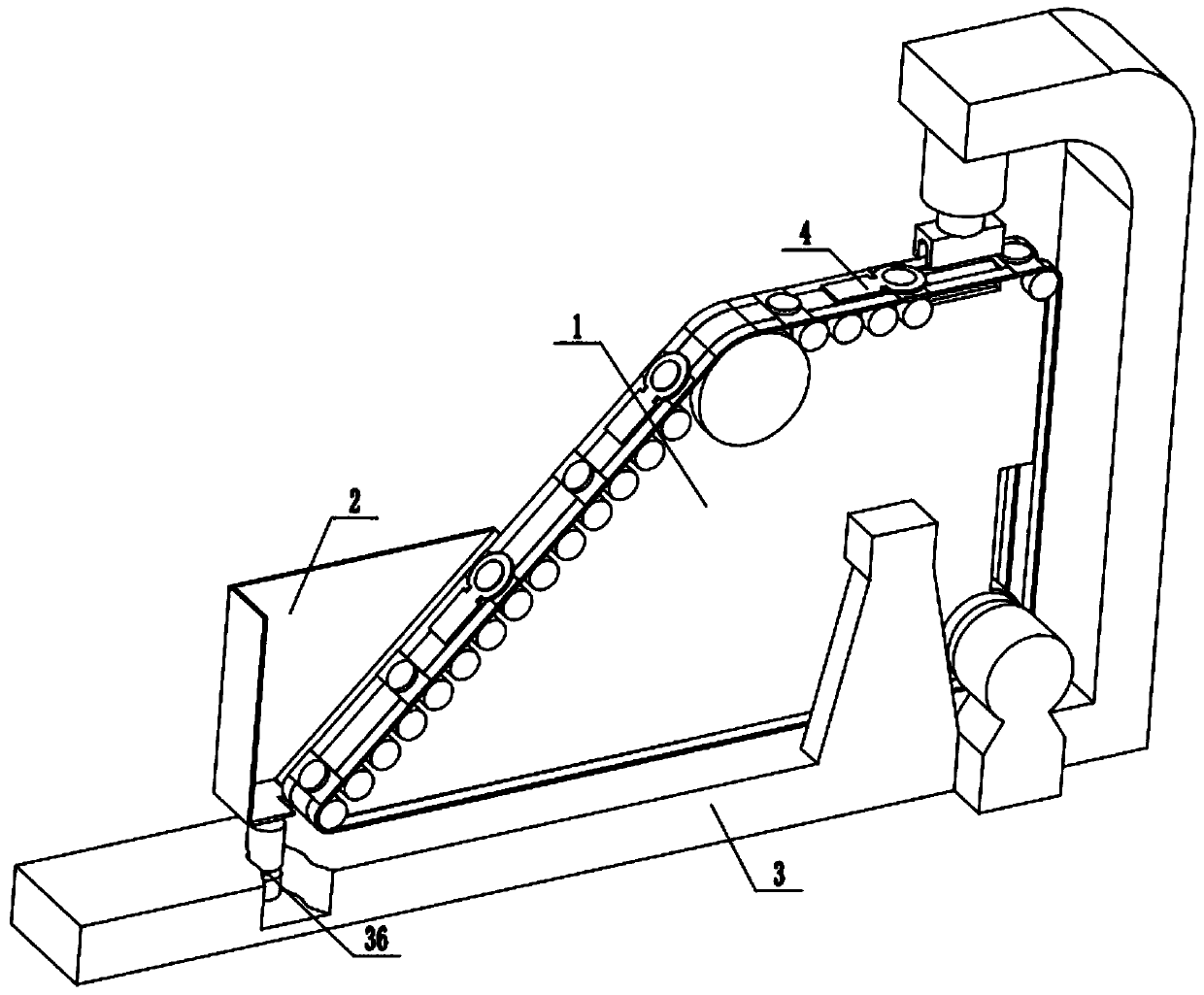

[0025] A bending machine for wire crimping parts, including a conveying mechanism 1, a hopper 2, a bracket 3, and a wire crimping part 4. The wire crimping part 4 is a part to be punched, and the conveying mechanism 1 is fixed on the bracket through a fixing frame 31 3, the hopper 2 is installed on the support 3 through a vibrator 36, and the vibrator 36 is generally driven by hydraulic pressure or air pressure, and can be driven by an electric motor.

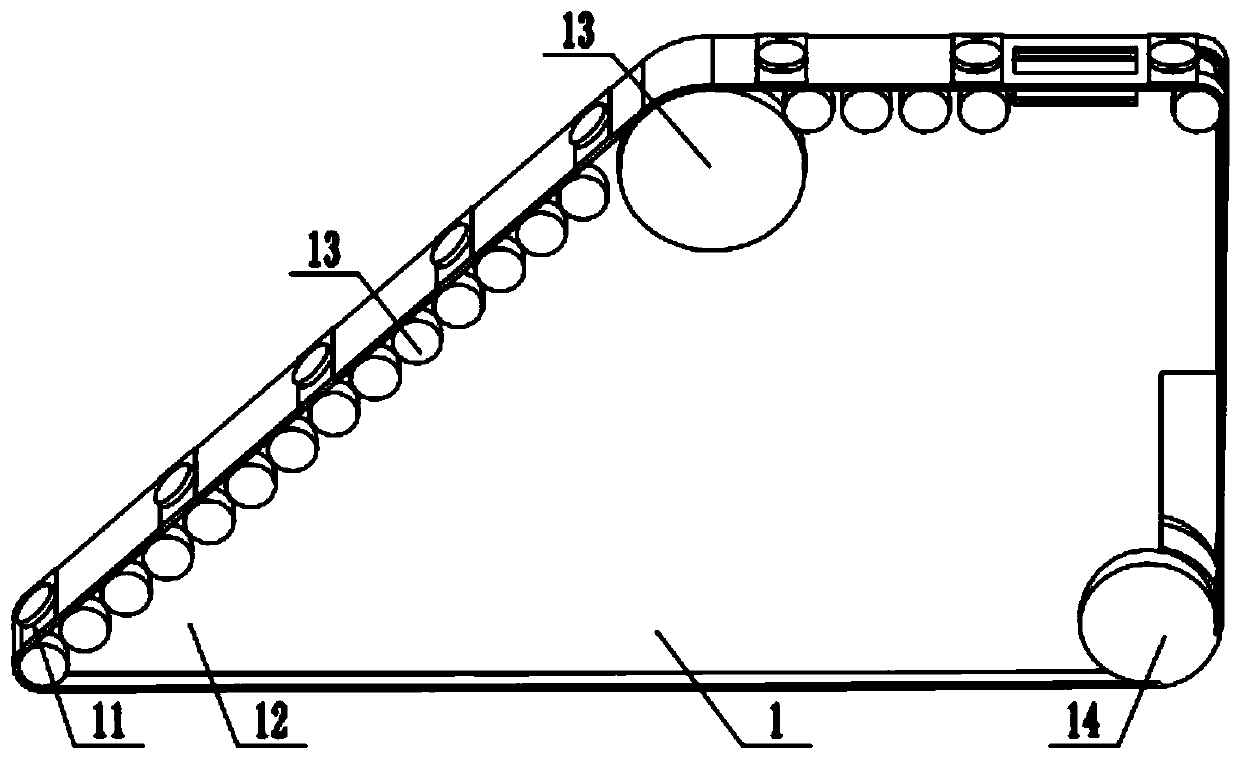

[0026] Described conveying mechanism 1 comprises conveyor belt 11, support member 12, support roller 13, and support member 12 comprises support plate 121, driving friction wheel 14, and support plate 121 is a trapezoidal plate, and generally used support plate 121 is a right-angled trapezoidal plate; Plate 121 includes guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com