High-voltage electrostatic dust collector cathode plate

A high-voltage electrostatic and cathode plate technology, which is applied to the cathode plate of high-frequency vibration cleaning and the cathode plate of high-voltage electrostatic precipitator, can solve the problem of reducing the service life of components, fatigue damage of stress-concentrated parts of structural components, and destroying the overall structure of the precipitator, etc. problems, to achieve the effect of prolonging the service life, avoiding resonance and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

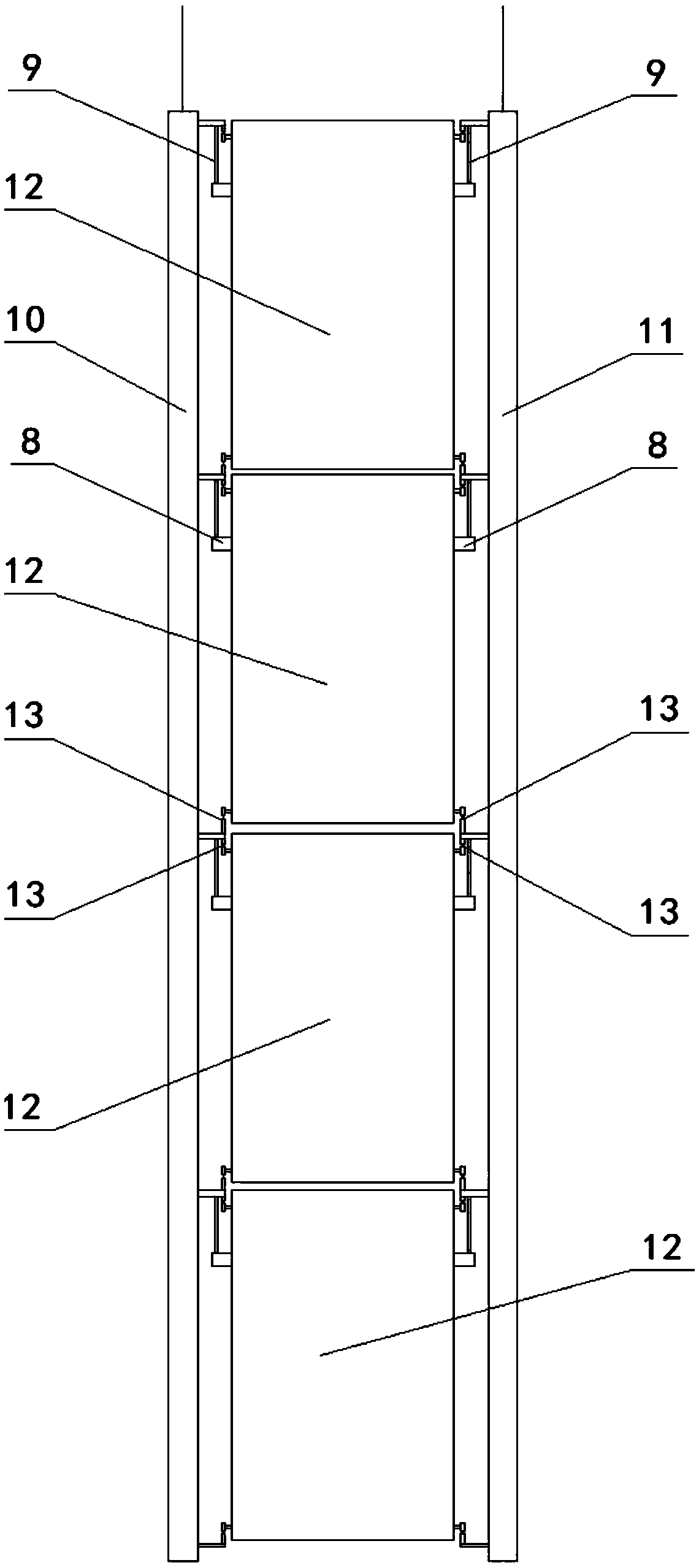

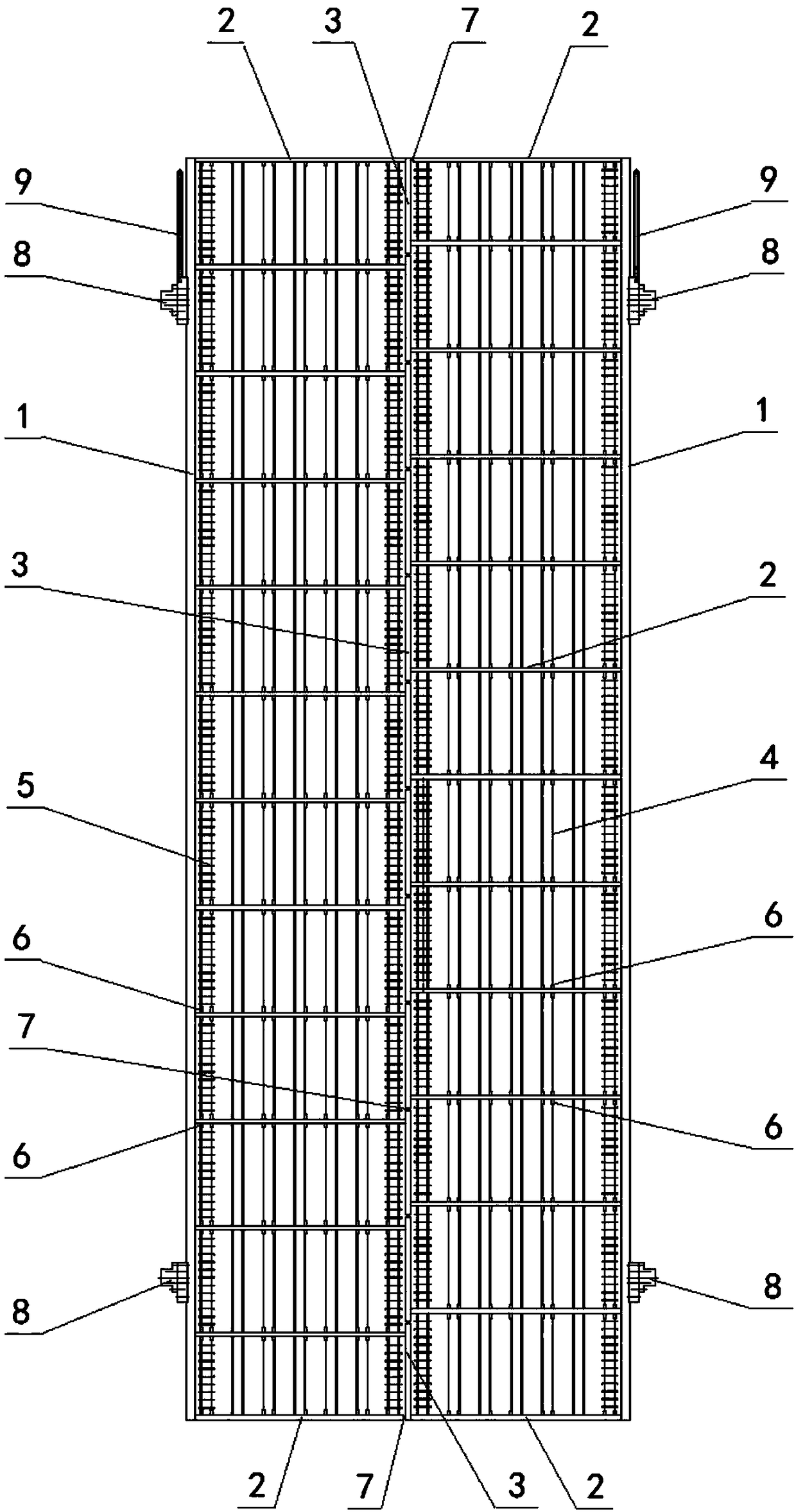

[0044] combine figure 1 and figure 2 , a cathode plate of a high-voltage electrostatic precipitator, placed inside the dust removal chamber through a left large frame 10 and a right large frame 11 and connected to the cathode of a constant-current high-voltage power supply. The cathode plate is composed of a plurality of modules 12 arranged sequentially between the left large frame 10 and the right large frame 11 from top to bottom. The modules 12 are hoisted on the left large frame 10 and the right large frame 11 by flexible steel wire ropes. The modules 12 are A rectangular grid structure composed of two main vibrating rods 1, several horizontal secondary vibrating rods 2, several vertical secondary vibrating rods 3, and several cathode strips 4 evenly distributed with cathode needles 5. Each rectangular grid in the module 12 is non-closed, which can dissipate vibration energy and prevent the components of the module 12 from resonating. The stiffness of the primary vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com