A precise vaccine preparation method based on soft etching and layer-by-layer self-assembly technology

A layer-by-layer self-assembly and vaccine preparation technology, applied in the field of vaccine preparation, can solve the problems of uncontrollable virus inactivation rate, complex components, and low effective content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

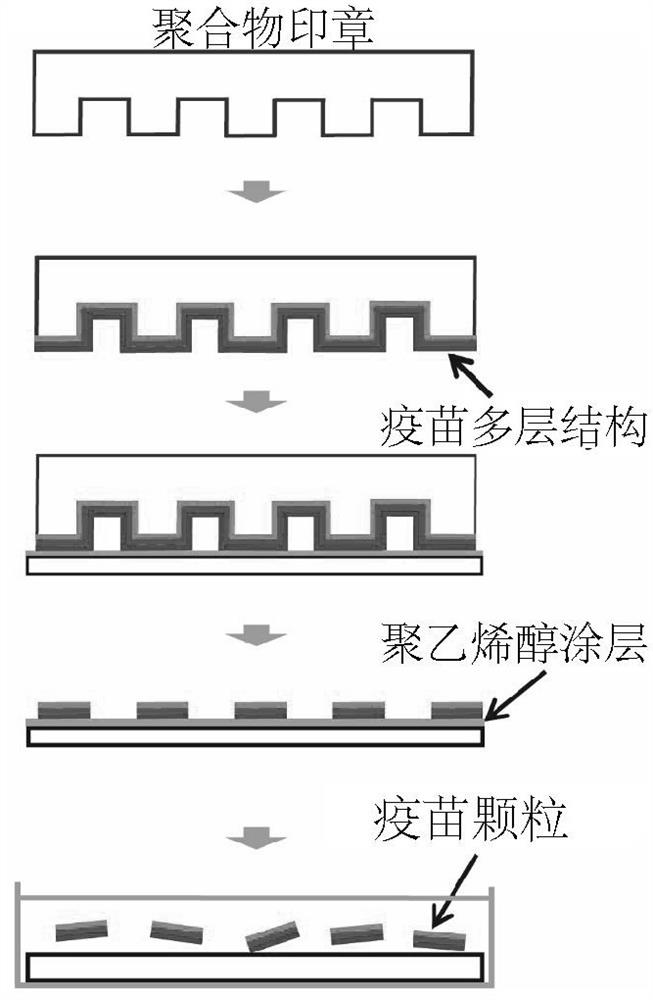

[0023]Precision vaccine preparation method based on soft etching and layer self-assembly technology, including steps:

[0024](1) The polydimethylsiloxane polymer seal substrate is soaked in a concentration of 0.1% to a DNA adjuvant aqueous solution and a polypeptide anti-stock solution, each soaking time is 10-15 minutes, according to the polypeptide in aqueous solution The charge characteristics, moderate modification of the polypeptide (nine polycrystine molecules to the polypeptide molecule end) such that the polypeptide can be charged. The amount of the polymer seal in the adjuvant, the number of times in the antigen solution depends on the amount of the components required in the vaccine, the more the amount of the immersion is increased accordingly.

[0025](2) Blow the polymer seal by nitrogen in a sterile environment.

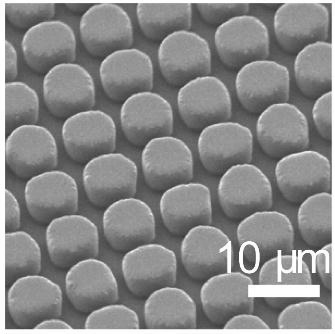

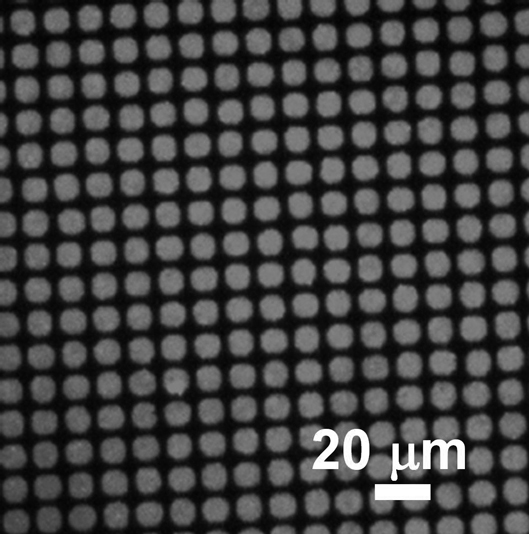

[0026](3) Print the polymer seal to a smooth substrate surface coated with a 10% polyvinyl alcohol film, thereby transferring the multilayer vaccine in the seal to t...

Embodiment 2

[0030]Precision vaccine preparation method based on soft etching and layer self-assembly technology, including steps:

[0031](1) The polydimethylsiloxane polymer seal substrate is soaked in a concentration of 0.001% in a DNA adjuvant aqueous solution and a polypeptide anti-stock solution, each soaking time is 10-15 minutes, according to the polypeptide in aqueous solution. The charge characteristics, moderate modification of the polypeptide (nine polycrystine molecules to the polypeptide molecule end) such that the polypeptide can be charged. The seal of the polymer seal is in the adjuvant, the number of soaking times in the antigen solution depends on the amount of components required in the vaccine.

[0032](2) Blow the polymer seal by nitrogen in a sterile environment.

[0033](3) Print the polymer seal to a smooth substrate surface coated with a 15% polyvinyl alcohol film, thereby transferring the multilayer vaccine microbial structure on the seal to the thin layer of polyvinyl alcohol....

Embodiment 3

[0037]Precision vaccine preparation method based on soft etching and layer self-assembly technology, including steps:

[0038](1) The polydimethylsiloxane polymer seal substrate is soaked in a concentration of 0.05% in an aqueous solution of the RNA adjuvant aqueous solution and the peptide anti-stock solution, each soaking time is 15 minutes, according to the charge characteristics of the polypeptide in aqueous solution Moderate modification of the polypeptide (nine polycrystine molecules to the polypeptide molecule) such that the polypeptide can be charged. The seal of the polymer seal is in the adjuvant, the number of soaking times in the antigen solution depends on the amount of components required in the vaccine.

[0039](2) Blow the polymer seal by nitrogen in a sterile environment.

[0040](3) Print the polymer seal to a smooth substrate surface coated with a 5% polyvinyl alcohol film, thereby transferring the multilayer vaccine microbial structure on the seal to the thin layer of pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com