Precision vaccine preparation method based on soft etching and layer-by-layer self-assembly

A technology of layer-by-layer self-assembly and vaccine preparation, applied in the field of vaccine preparation, can solve the problems of low effective content, uncontrollable virus inactivation rate, complex components, etc., and achieve the effect of reducing uneven performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

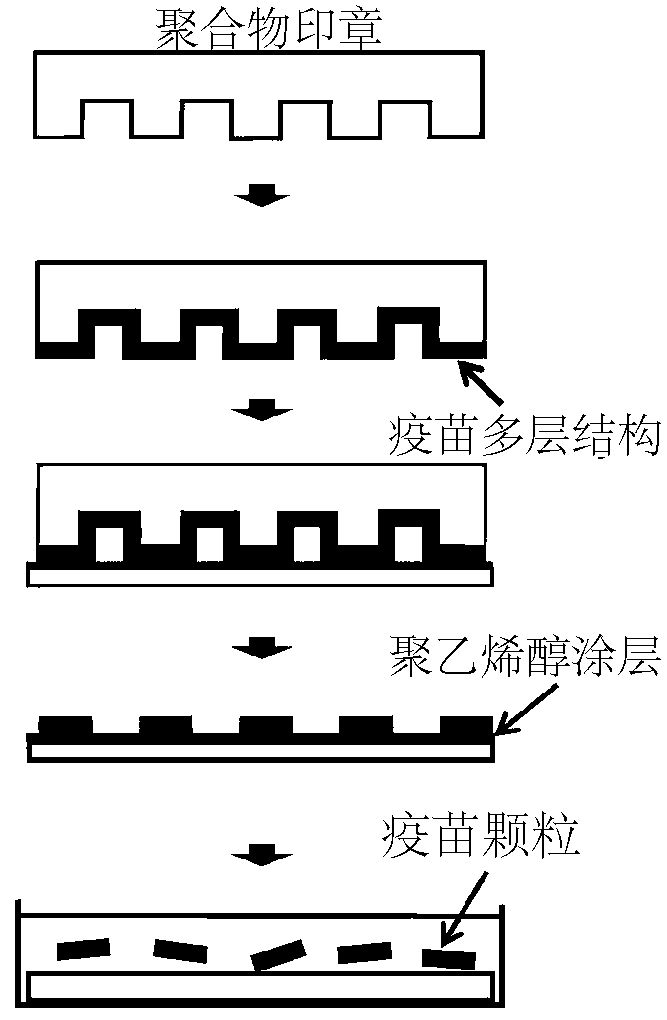

[0023] A precise vaccine preparation method based on soft etching and layer-by-layer self-assembly technology, including steps:

[0024] (1) Soak the polydimethylsiloxane polymer stamp substrate in a 0.1% DNA adjuvant aqueous solution and a polypeptide antigen solution in turn, each soaking time is 10-15 minutes, depending on the concentration of the polypeptide in the aqueous solution Charged properties, the polypeptide needs to be moderately modified (linking 9 polyarginine molecules to the end of the polypeptide molecule), so that the polypeptide can be positively charged. The times of immersion of the polymer stamp in the adjuvant and antigen solution depend on the amount of each component required in the vaccine, the more the required amount, the more times of immersion.

[0025] (2) Blow dry the polymer stamp with nitrogen in a sterile environment.

[0026] (3) The polymer stamp was printed on the surface of a smooth substrate coated with 10% polyvinyl alcohol film, so ...

Embodiment 2

[0030] A precise vaccine preparation method based on soft etching and layer-by-layer self-assembly technology, including steps:

[0031] (1) Soak the polydimethylsiloxane polymer stamp substrate in the DNA adjuvant aqueous solution and the polypeptide antigen solution in turn at a concentration of 0.001%, each soaking time is 10-15 minutes, according to the concentration of the polypeptide in the aqueous solution Charged properties, the polypeptide needs to be moderately modified (linking 9 polyarginine molecules to the end of the polypeptide molecule), so that the polypeptide can be positively charged. The number of immersion times of the polymer stamp in the adjuvant and antigen solution depends on the amount of each component required in the vaccine.

[0032] (2) Blow dry the polymer stamp with nitrogen in a sterile environment.

[0033] (3) The polymer stamp was printed on the surface of a smooth substrate coated with 15% polyvinyl alcohol film, so that the multi-layer va...

Embodiment 3

[0037] A precise vaccine preparation method based on soft etching and layer-by-layer self-assembly technology, including steps:

[0038] (1) Soak the polydimethylsiloxane polymer stamp substrate in an aqueous solution of RNA adjuvant with a concentration of 0.05% and a polypeptide antigen solution in turn, each soaking time is 15 minutes, according to the charging characteristics of the polypeptide in the aqueous solution , the polypeptide needs to be moderately modified (9 polyarginine molecules are linked to the end of the polypeptide molecule), so that the polypeptide can be positively charged. The number of immersion times of the polymer stamp in the adjuvant and antigen solution depends on the amount of each component required in the vaccine.

[0039] (2) Blow dry the polymer stamp with nitrogen in a sterile environment.

[0040] (3) The polymer stamp was printed on the surface of a smooth substrate coated with 5% polyvinyl alcohol film, so that the multi-layer vaccine m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com