Cyclone separation device and air purification device

A technology of cyclone separation device and gas purification device, which is applied in the direction of suction filter, cleaning equipment, vacuum cleaner, etc., can solve the problems of complex structure, poor separation effect, and many parts, and achieve the effect of simple equipment and avoiding air flow disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

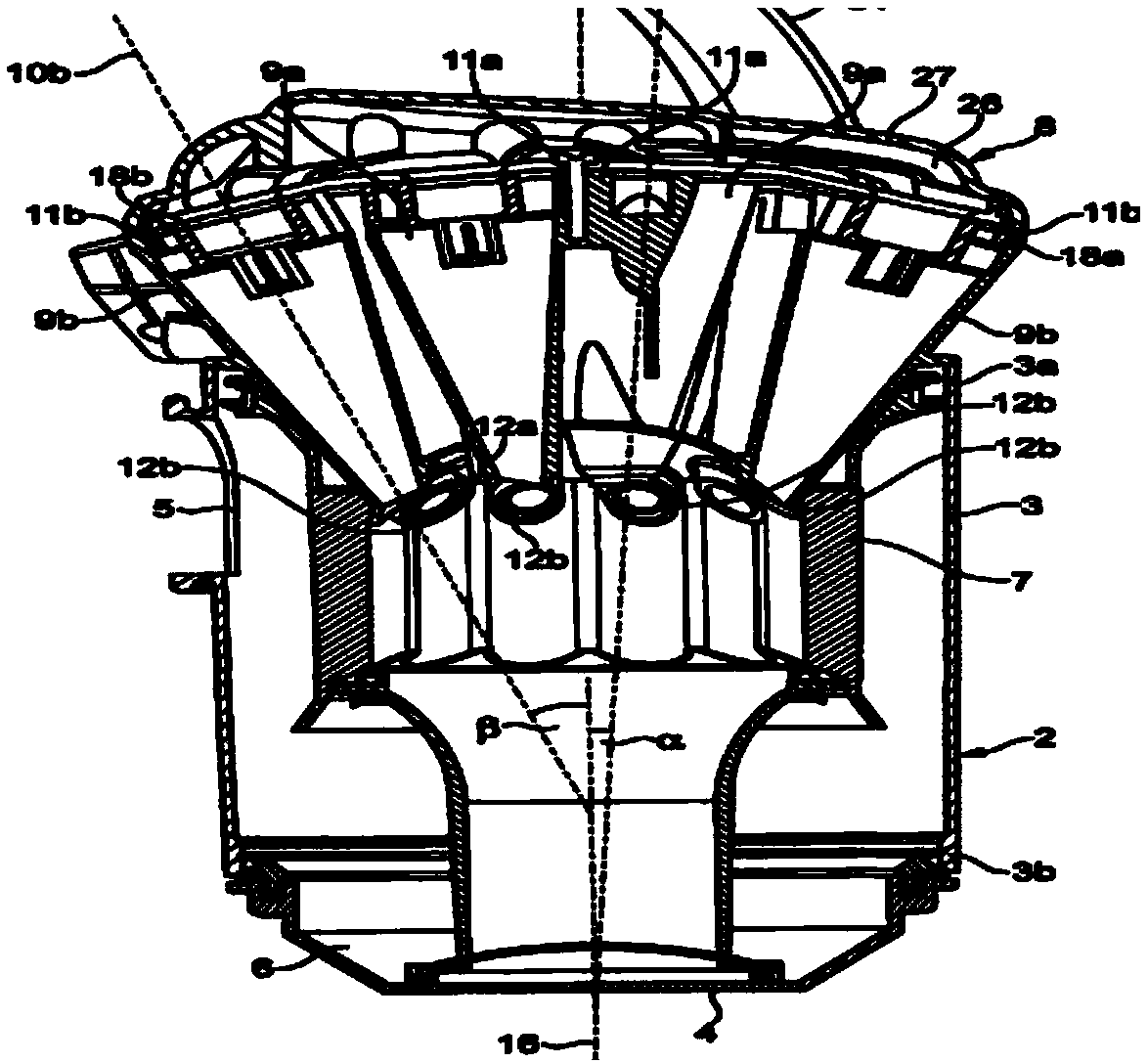

[0041] Figure 3 to Figure 5 As shown, a kind of cyclone separation device provided for the present embodiment comprises:

[0042] The cup body 1 is provided with a cup body air inlet 11 on the side wall, and a cup inner tube 12 is formed upward at the bottom;

[0043] Separator 2, a through hole is formed in the middle to cooperate with the inner tube 12 of the cup, so that the separator 2 can be detachably arranged inside the cup body 1. In this embodiment, the through hole is socketed On the inner tube 12 of the cup, in order to ensure that there is no gap at the junction of the separator 2 and the inner tube 12 of the cup, the two are assembled using an interference fit relationship, and the side wall of the separator 2 and the cup body 1 should also be satisfied. The inner side walls are in seamless contact or form a closed space. In this embodiment, the upper edge of the outer wall of the separator 2 is provided with positioning ribs 25 extending away from the longitudi...

Embodiment 2

[0054] This embodiment provides a gas purification device, specifically a vacuum cleaner, comprising:

[0055] The cyclone separation device described in Embodiment 1 above also has the technical advantages it possesses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com