Push rod clamping type rope towing system and working method thereof

A rope and push rod technology, which is applied to the field of push rod clamping type rope towing systems, can solve the problem that the float ball, the rope rope or the seedling rope cannot be smoothly hooked, the operation efficiency is not significantly improved, and the float ball is easily crushed. and other problems, to achieve the effect of ingenious action design, improved work efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

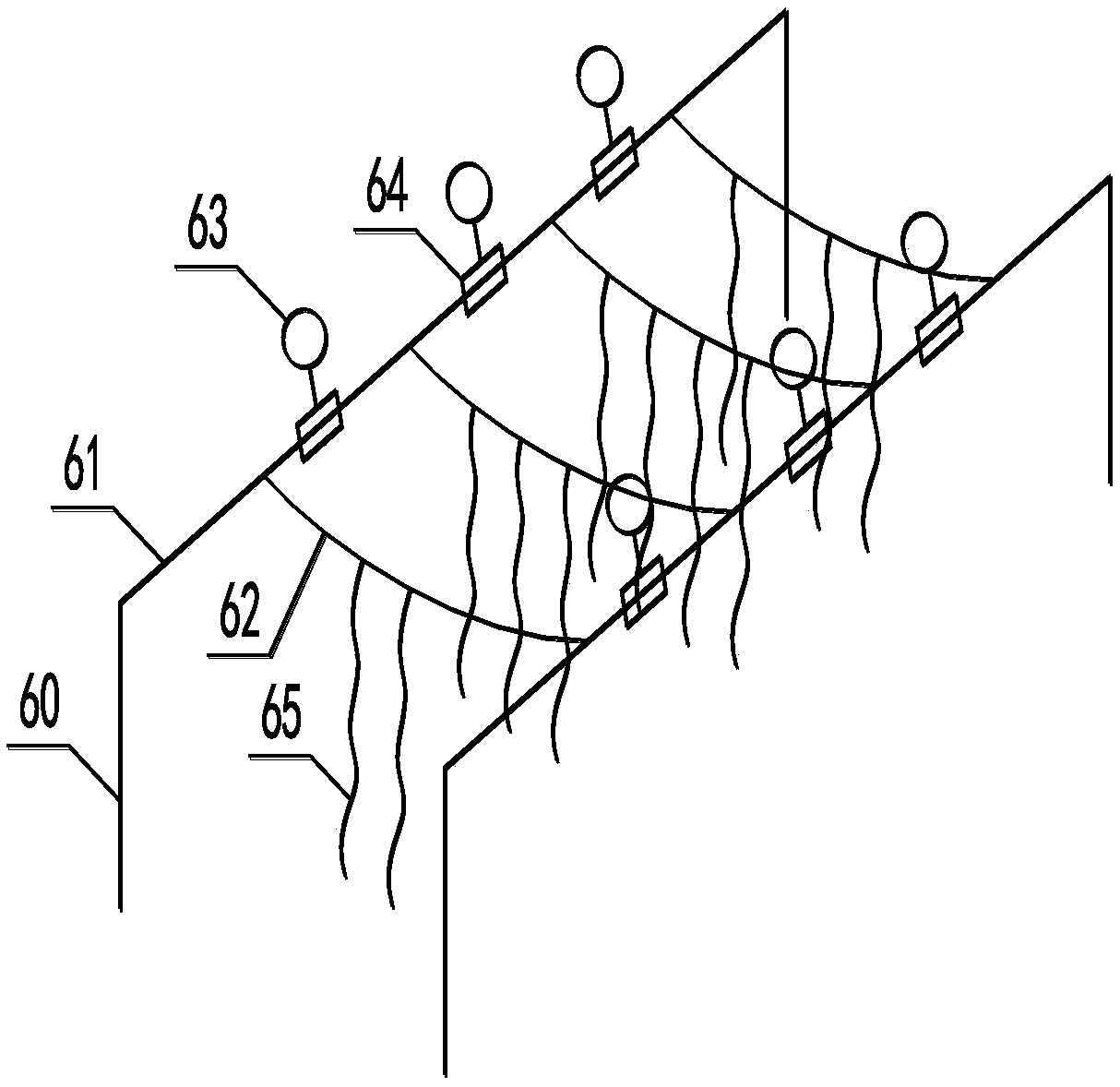

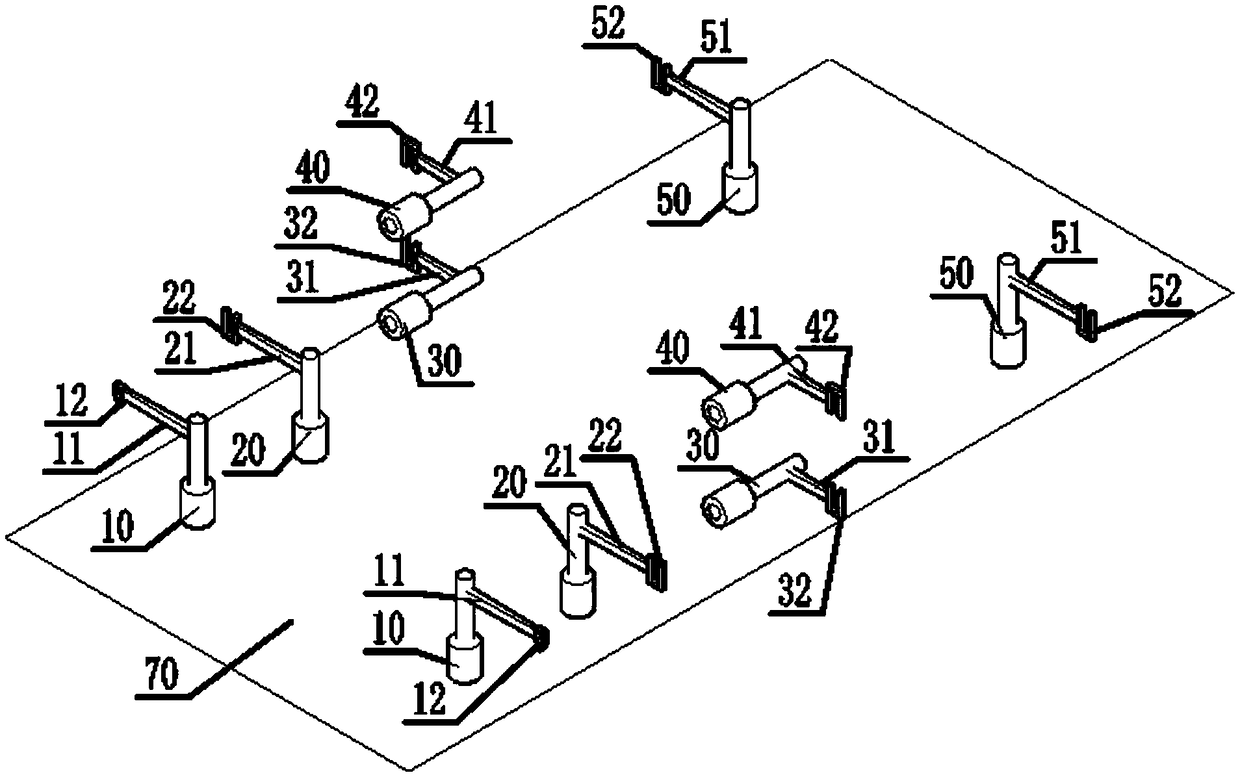

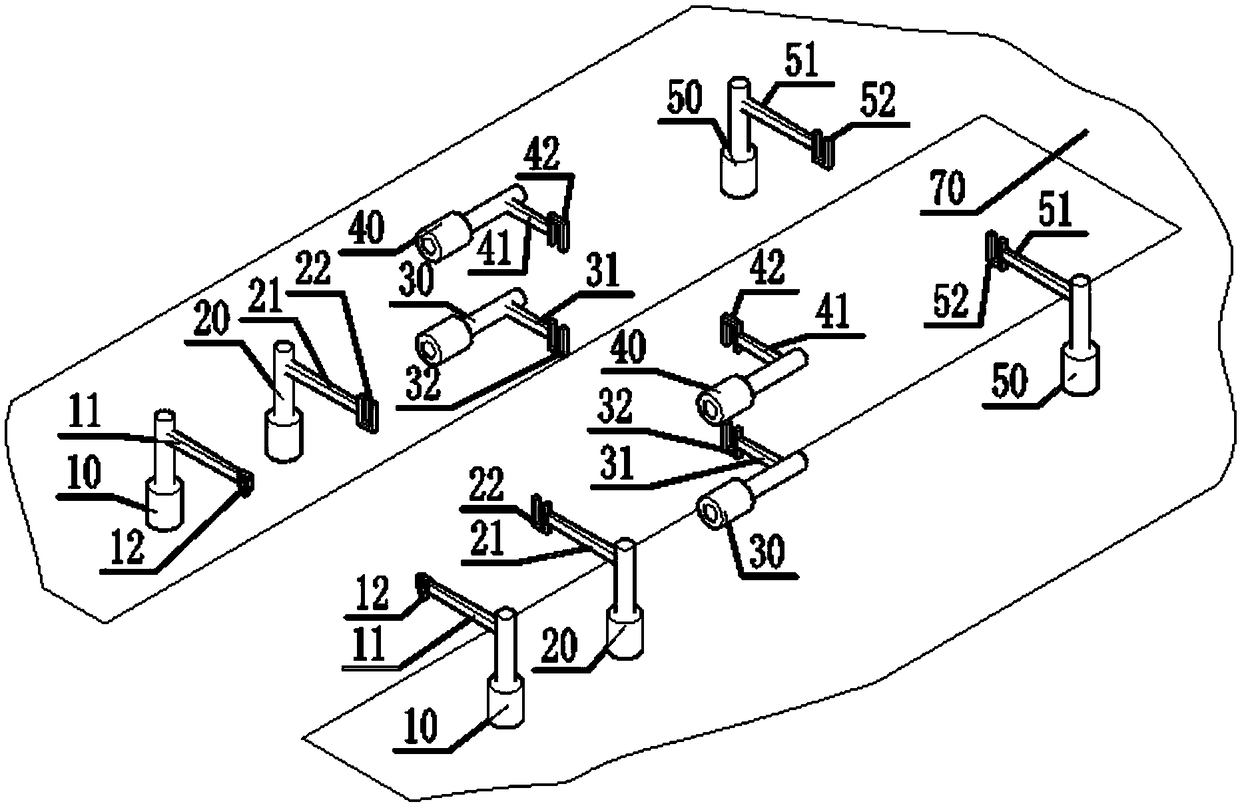

[0028] see Figure 1-6 , the push rod clamping type rope towing system, including an electro-hydraulic push rod 10 extending and contracting in the vertical direction, an electro-hydraulic push rod 20 extending and contracting in the vertical direction, and an electro-hydraulic push rod 30 extending and contracting in the ship's length direction arranged in sequence; Placed directly above the electrohydraulic pushrod 30, the electrohydraulic pushrod 40 stretches along the length of the ship; the electrohydraulic pushrod 50 stretches vertically; the support arm 11 connecting the electrohydraulic pushrod 10 and the guide limit frame 12; Connect the support arm 21 of the electrohydraulic push rod 20 and the clamp 22; connect the support arm 31 of the electrohydraulic push rod 30 and the clamp 32; connect the support arm 41 of the electrohydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com