Server heat dissipation box with dust proof function

A technology for servers and cooling boxes, which is applied in the fields of instrumentation, cooling/ventilation/heating transformation, electrical digital data processing, etc. It can solve the problems of dust affecting the service life of servers, and achieve the effect of accelerating air flow and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

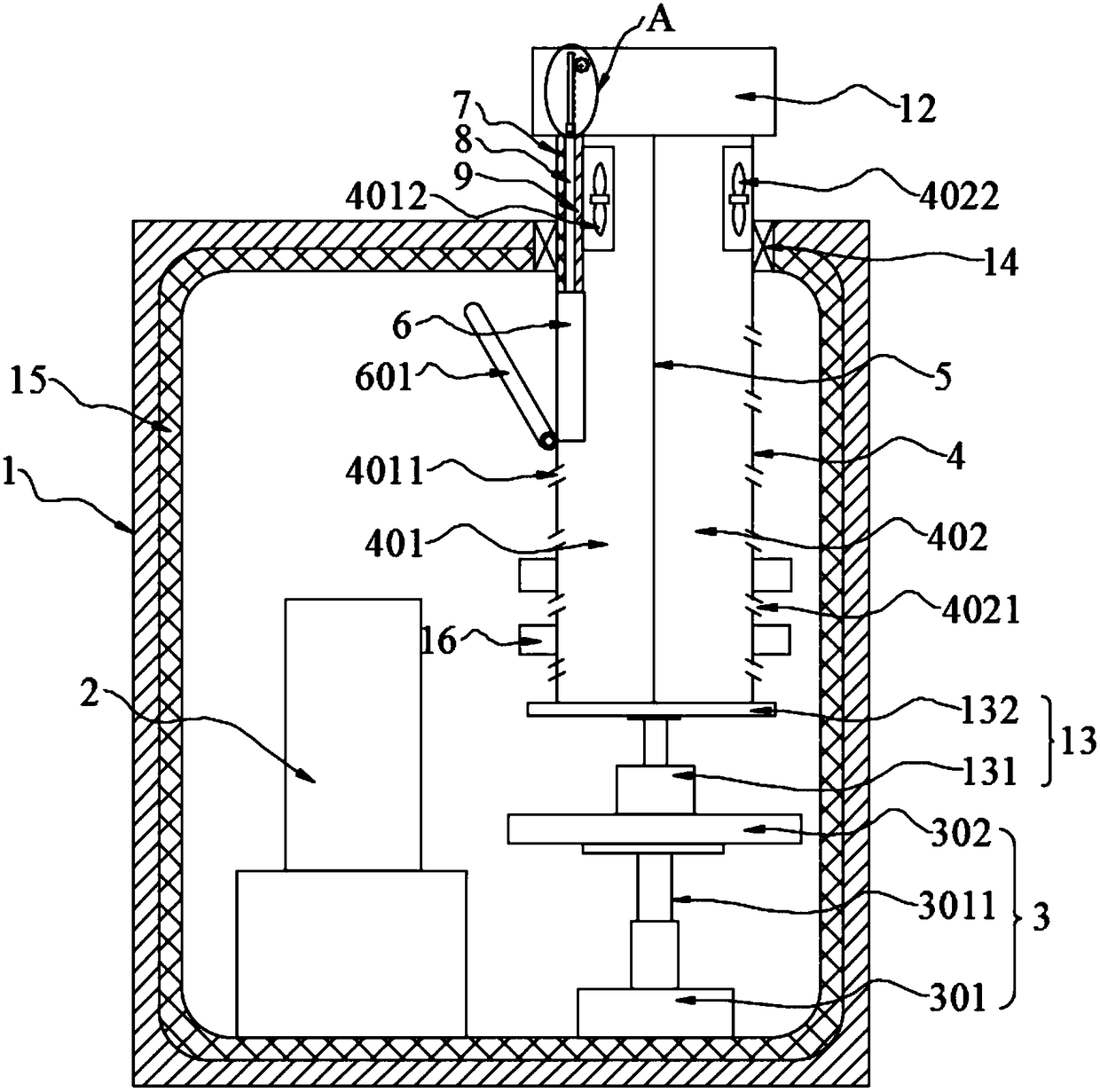

[0032] This embodiment is further optimized on the basis of Embodiment 1 as follows: the lifting device 3 includes a hydraulic cylinder 301 and a lifting plate 302, the telescopic shaft 3011 of the hydraulic cylinder 301 is connected to the lifting plate 302, and the lifting plate 302 is connected to each other. The upper end of the plate 302 is connected to the rotating device 13 .

[0033] After adopting this technical solution, as a preferred manner, a smooth lift is provided for the guide tube 4 .

Embodiment 3

[0035] This embodiment is further optimized on the basis of Embodiment 1 as follows: the rotating device 13 includes a servo motor 131 and a rotating plate 132, the servo motor 131 is connected to the lower end of the rotating plate 132, and the rotating plate 132 The upper end and the guide tube 4 are connected to each other.

[0036]After adopting the scheme of this machine, the upper end of the lifting device 3 is provided with a rotating device for driving the rotation of the guide tube 4. During the heat dissipation process, the servo motor 131 works to drive the guide tube 4 to rotate continuously, and the rotation of the guide tube 4 A number of air intake holes on the side wall of the air intake do circular motion, so that when the cold air enters the interior of the housing 1 from the air intake passage, it can directly reach multiple angular positions in the housing 1, and at the same time pass through the guide tube 4 The stirring blade 16 arranged at the lower end ...

Embodiment 4

[0038] This embodiment is further optimized on the basis of embodiment 1 as follows: the inner wall of the housing 1 is further provided with a sound-insulating layer 15, and the material of the sound-insulating layer 15 is sound-absorbing cotton.

[0039] After adopting this technical solution, it can effectively reduce the transmission of the noise generated by the service to the outside of the casing 1 and cause noise pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com