In-plane-control-based active vibration control method for wrinkled film

A technology of active vibration control and pleats, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as wiring and installation difficulties, affecting structural dynamic performance, changing film stress distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The technical solution of the present invention is described in detail in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following implementation situations.

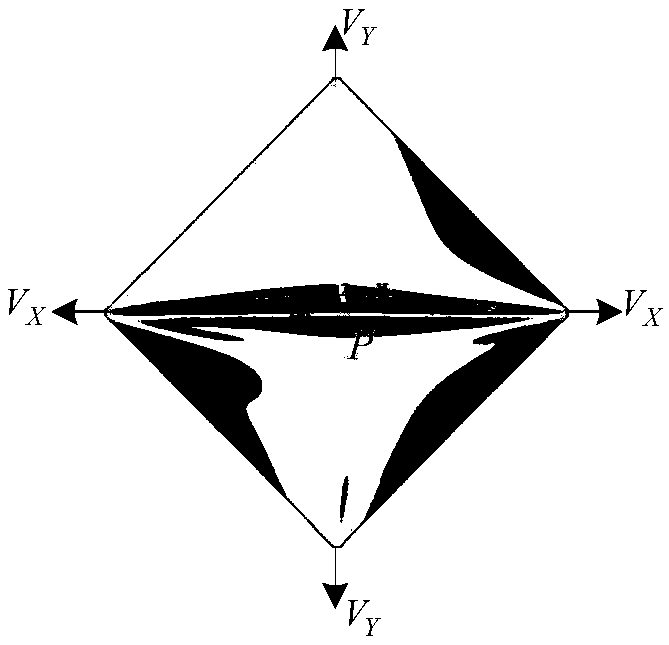

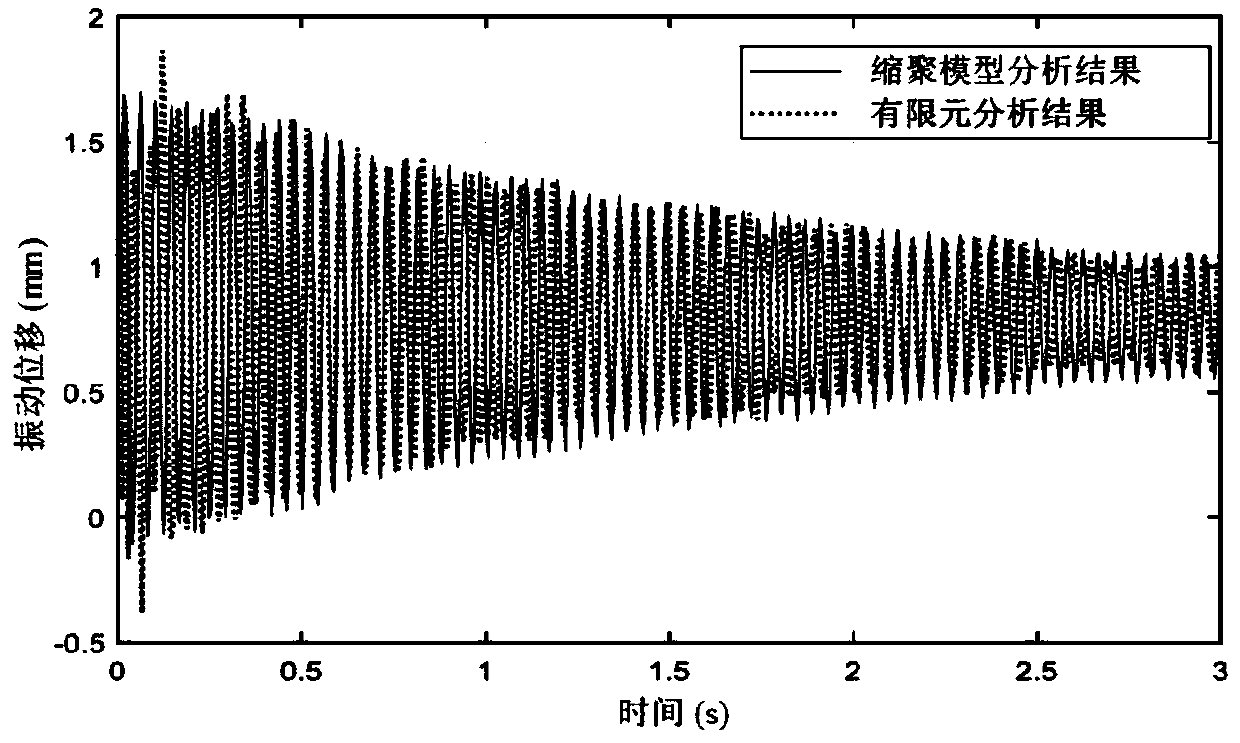

[0113] The active vibration control method of wrinkled film based on in-plane regulation of the present invention can add two groups of voice coil motor drive modules on the basis of the static experimental device, which are used to adjust the displacement in the X direction and the Y direction respectively, through the voice coil motor The slider is stretched to adjust the displacement of the cable, and the tension on the cable is changed. The tension sensor fixed on the slider of the voice coil motor is used to monitor the tension in real time, and the grating ruler outputs and feeds back the displacement in real time. A knocking device is installed on the back of the film, and the out-of-plane disturbance is simulated by the impact method, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com