Metering control method of rotor scale feeding device

A technology of a feeding device and a control method, which is applied in the field of control, and can solve problems such as material centroid deviation, increased material quantity difference, material centroid deviation, and increased consumption, so as to improve production efficiency and product quality, and increase the speed of adjustment and precision, reducing the effect of uneven material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

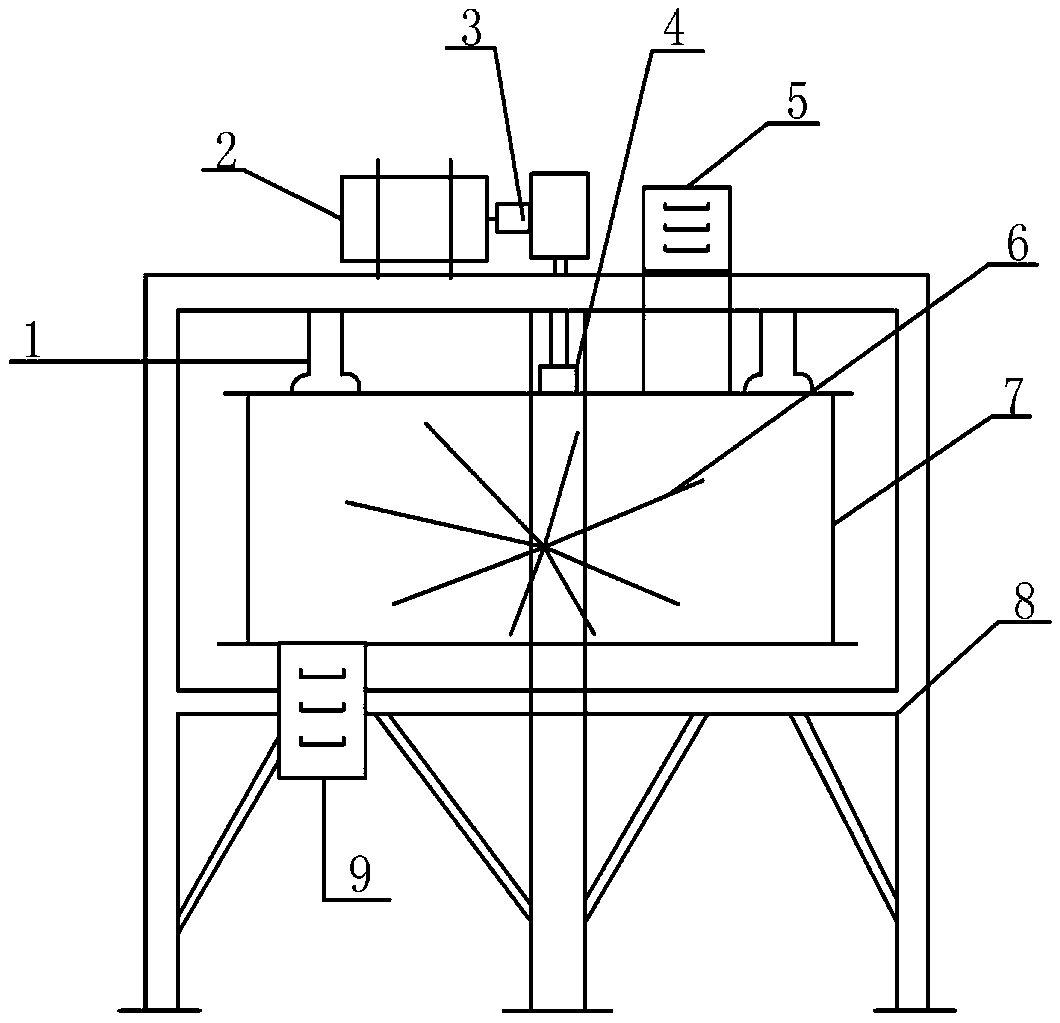

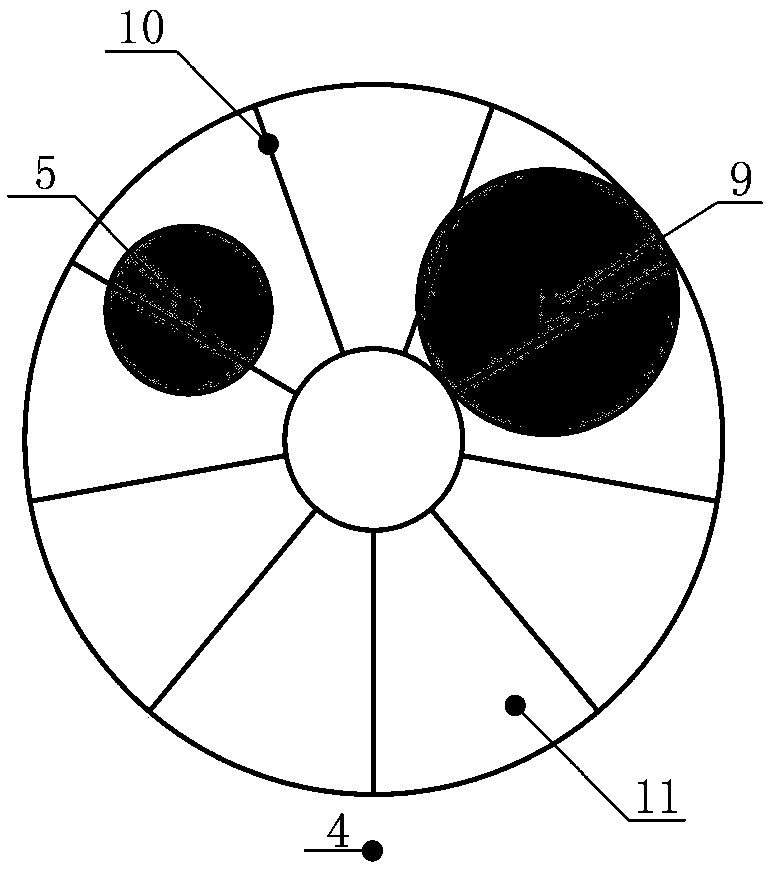

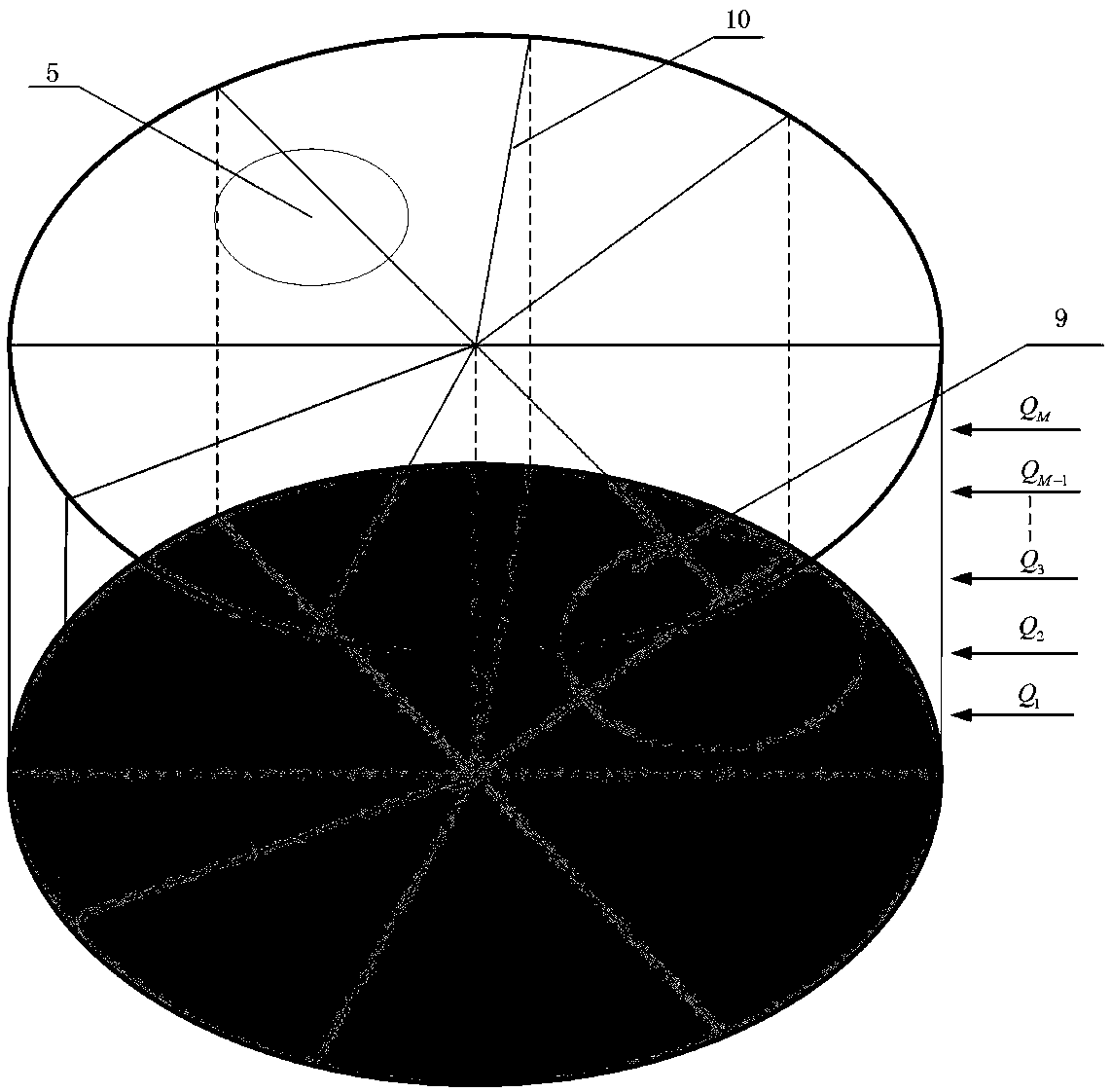

[0030] The present invention is an embodiment of a metering control method of a rotor scale feeding device, such as figure 1 As shown, a rotor scale feeding device for reference in this embodiment includes two hoisting bearings 1, a motor 2, a speed measuring device 3, a weighing device 4, a feed port 5, a rotary wheel 6, a scale body 7, Frame 8 and outlet 9.

[0031] The line connecting the two fulcrums of the two hoisting bearings 1 in the above device should coincide with the line connecting the centers of the feed inlet 5 and the outlet 9, and the two fulcrums are distributed symmetrically and equidistantly; The other side and on the centerline of the line connecting the fulcrums of the two hoisting bearings 1; there should be a feed port baffle on the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com