A solar photovoltaic photothermal heat collection device

A technology of solar photovoltaic and heat collection devices, which is applied in the direction of solar heat collectors, solar thermal energy, and solar thermal power generation, and can solve the adverse effects of electricity and heat comprehensive utilization efficiency heat collector operation reliability, photovoltaic cell module power generation efficiency and Reliability impact, poor heat resistance and thermal conductivity, etc., to achieve the effect of novel device structure, curbing the reduction of heat exchange intensity, uniform heat exchange and enhanced heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

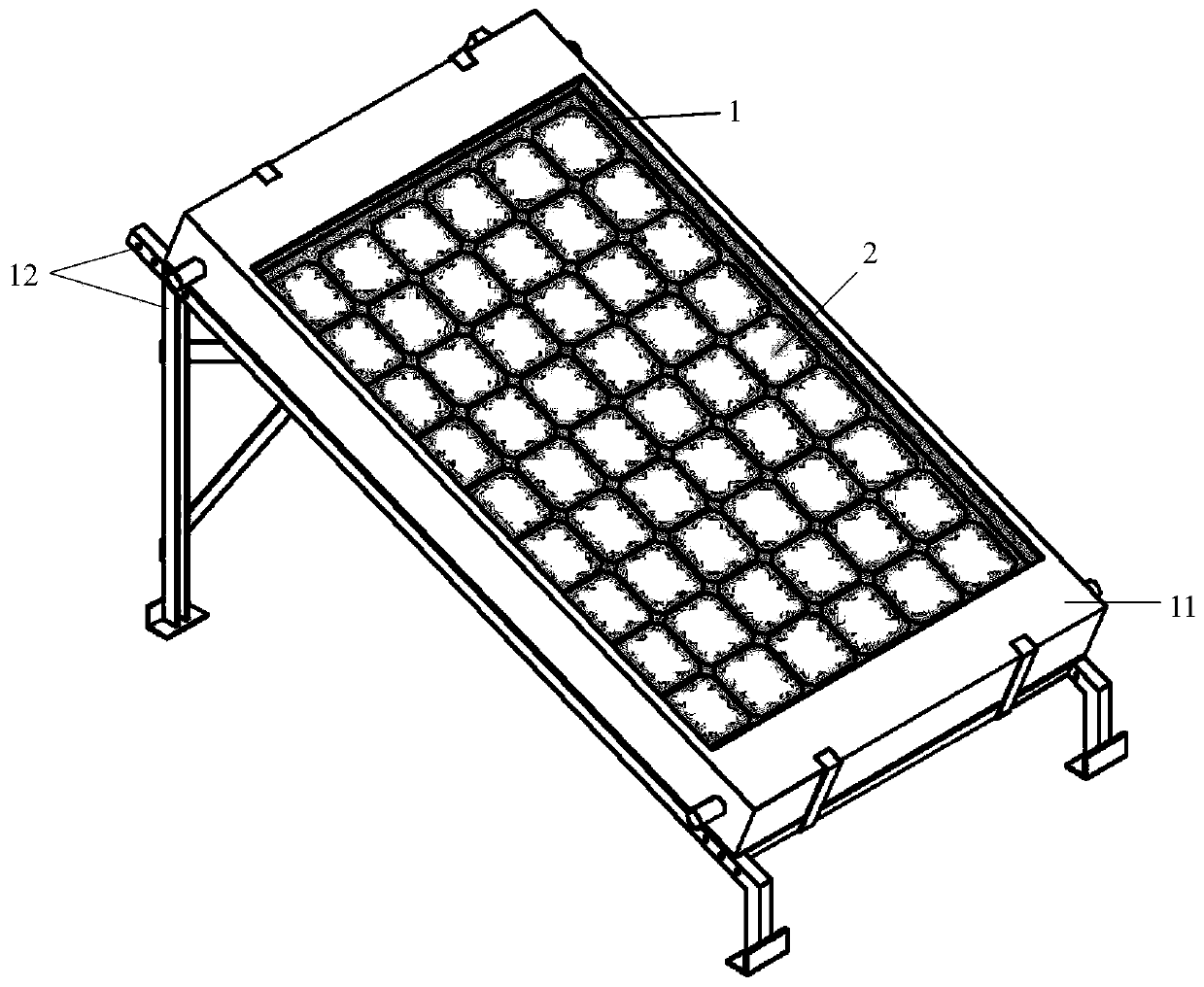

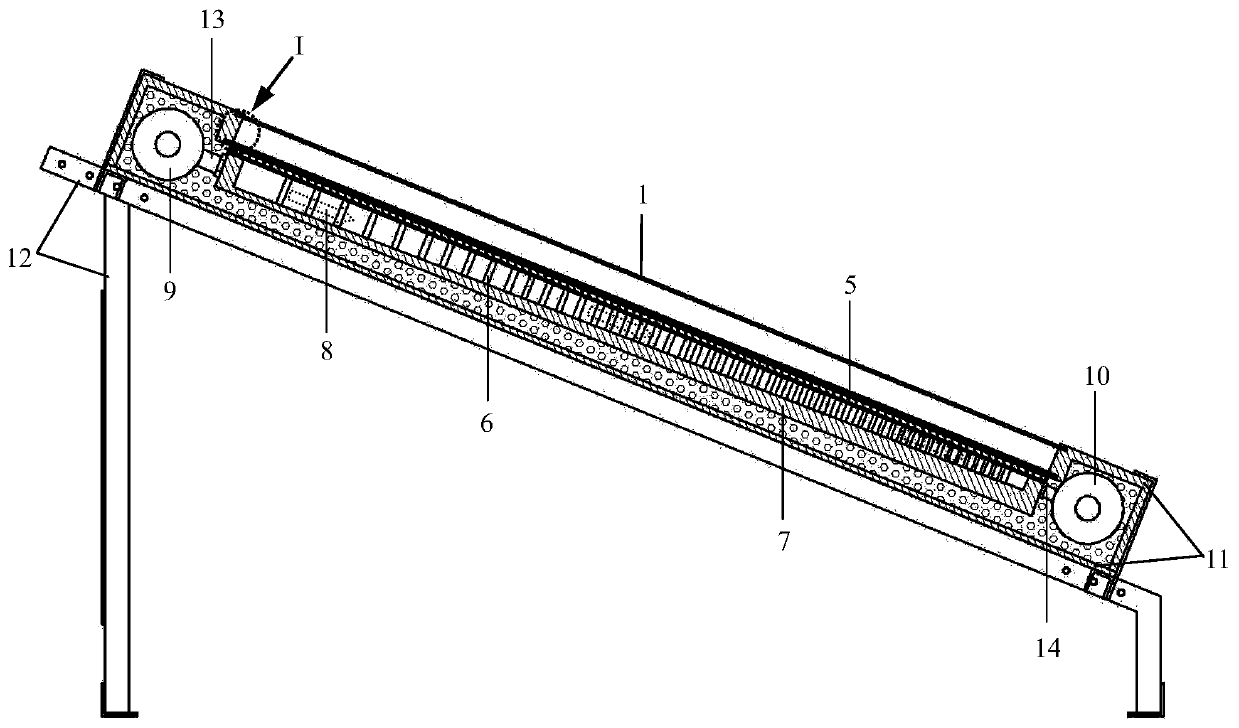

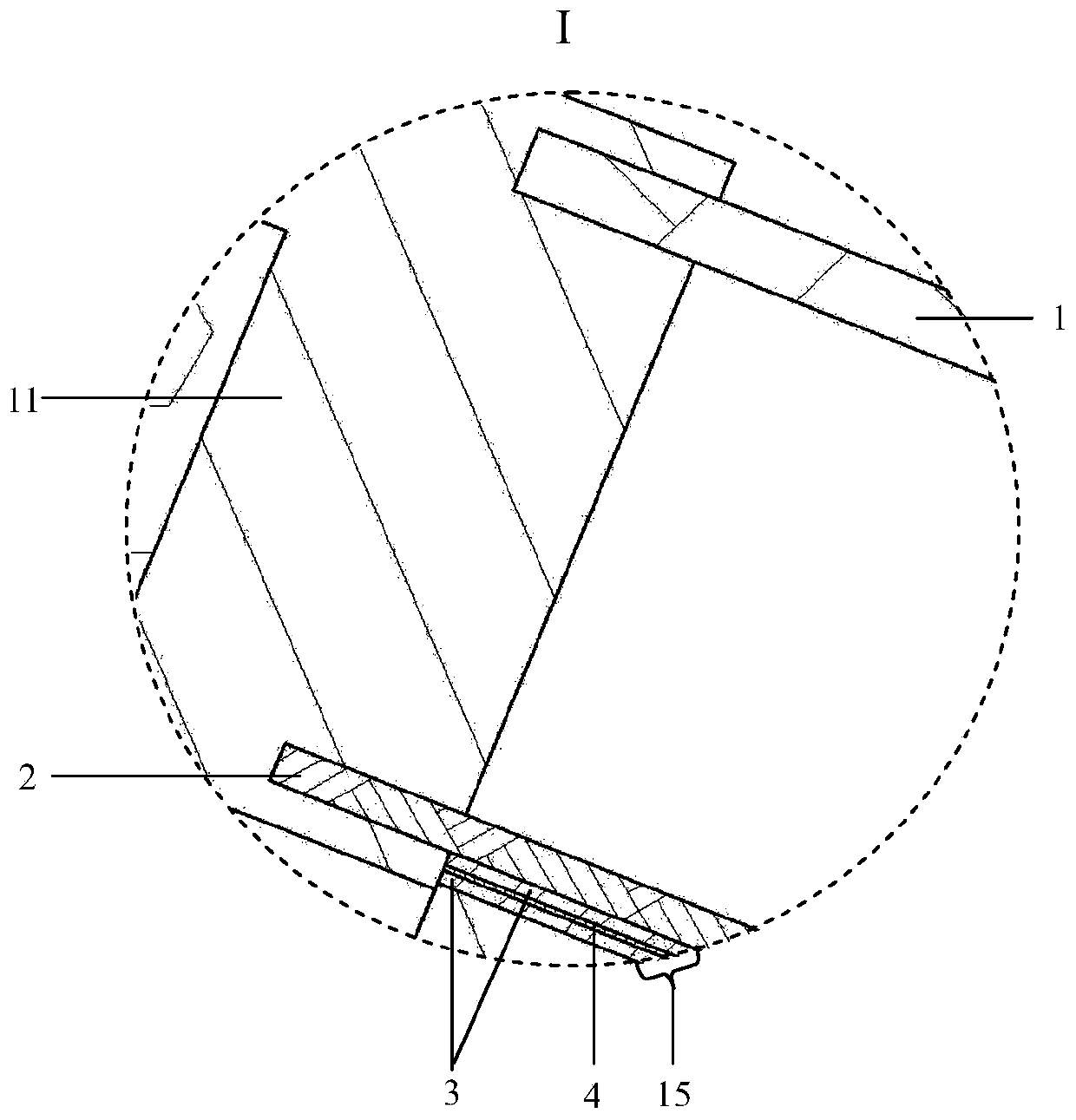

[0024] Such as Figure 1-5 As shown, a solar photovoltaic photothermal heat collection device includes a glass cover plate 1, a solar panel 2, an adhesive film layer 3, an insulating layer 4, a cover plate 5, micro-rib groups 6, a bottom plate 7, and a cold fluid header 9 , Thermal fluid header 10, thermal insulation shell 11, bracket 12, fluid inlet pipe 13, fluid outlet pipe 14.

[0025] Such as Figure 1-5 As shown, a solar photovoltaic photothermal heat collection device, a glass cover plate 1, a solar panel 2, and a heat collector plate 16 with a variable cross-section flow channel are fixed on the said heat collector along the light-facing side to the backlight side. Inside the thermal insulation shell 11; the variable cross-section flow channel heat collector plate 16 is formed by etching the bottom plate 7 of a plurality of parallel variable cross-section fluid ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com