Electric heating film heater and method for assembling the heater

An electric heating film and heater technology, which is applied in the field of household appliances, can solve the problems of easily damaged electric heating film, waste of materials, slow assembly efficiency of electric heating film heaters, etc., so as to improve the efficiency of assembly and wiring, reduce the difficulty of installation, and reduce the installation cost. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

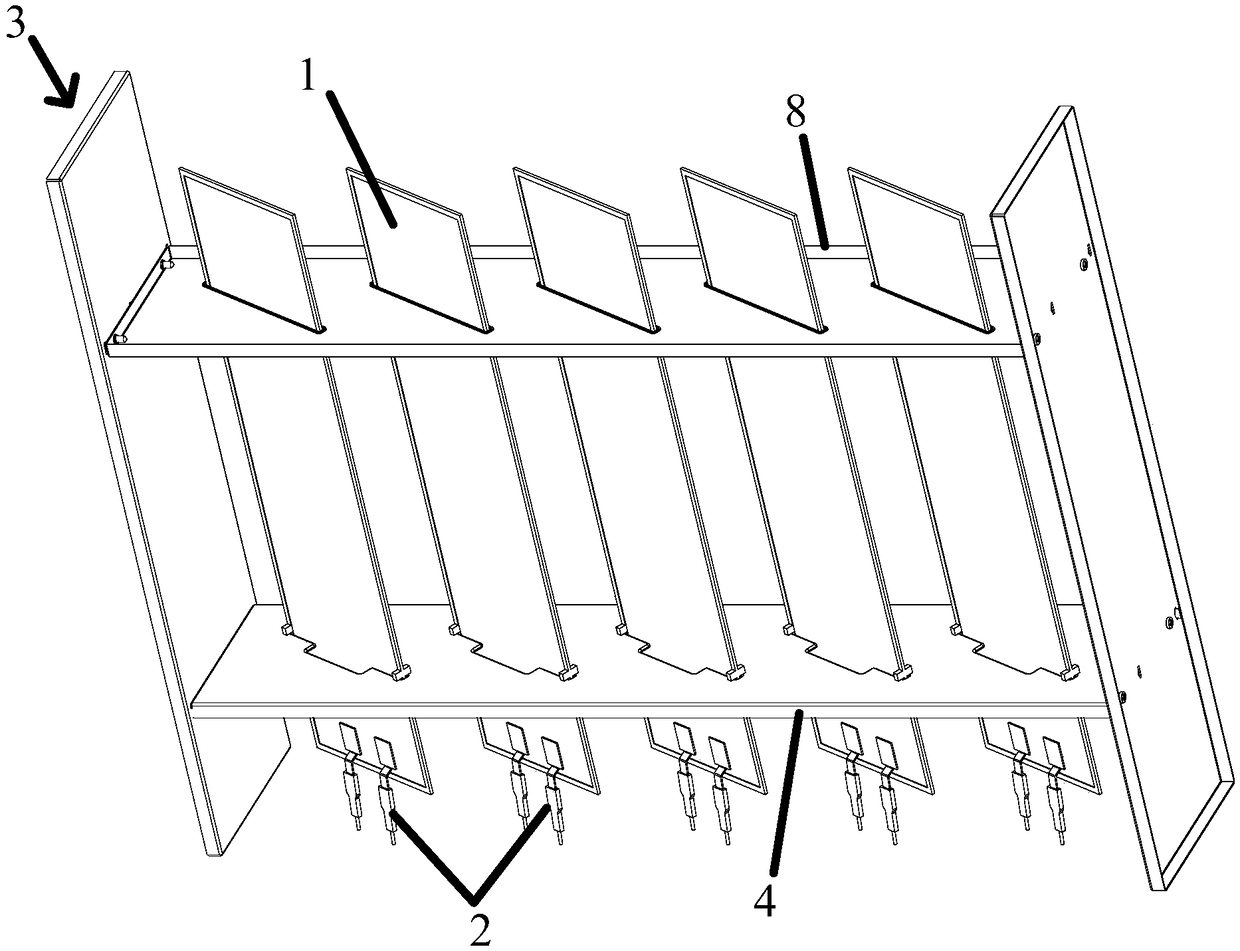

[0052] This embodiment provides an electric heating film heater, such as figure 1 and figure 2 shown, which includes

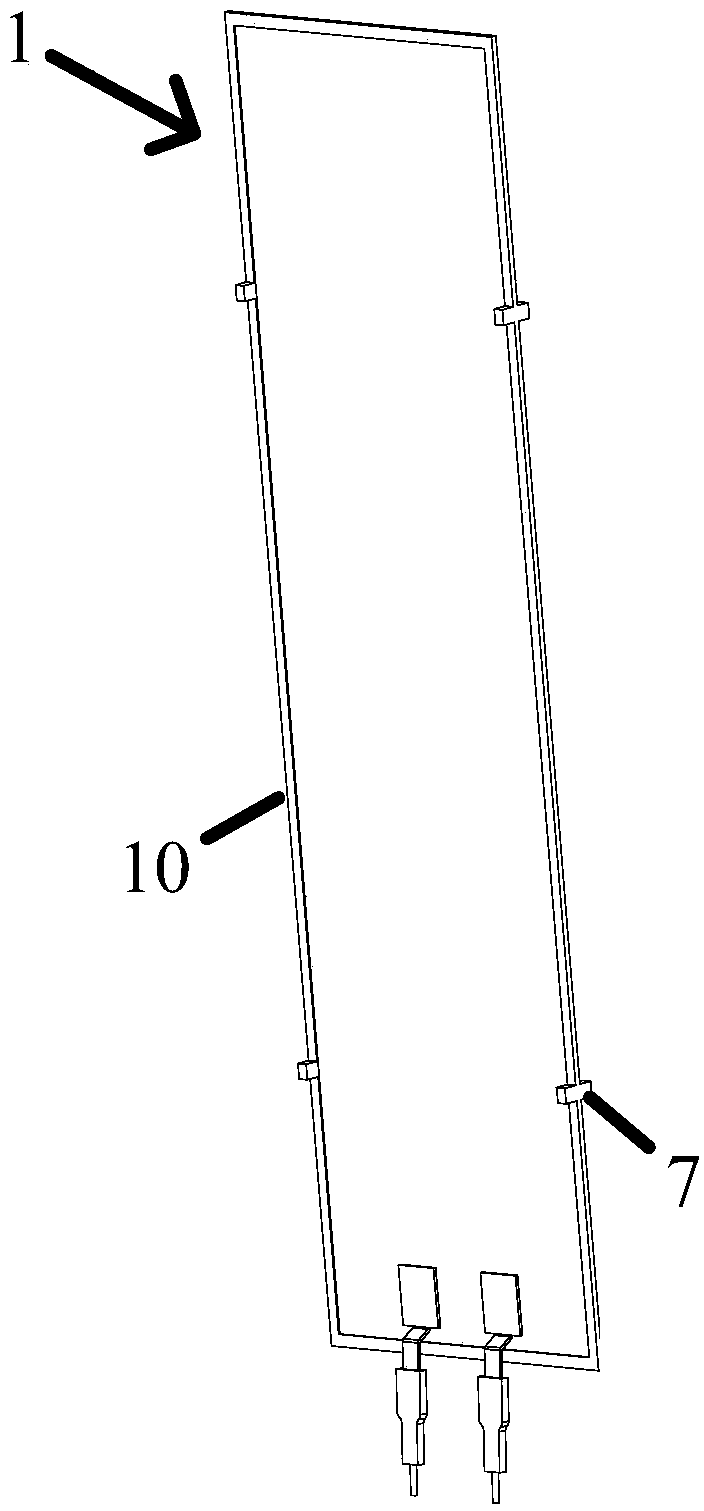

[0053] Electrothermal diaphragm 1, such as image 3 As shown, the lower end of the electrothermal diaphragm 1 is provided with a connecting terminal 2, and there are two connecting terminals 2 on each of the electrothermal diaphragm 1, and the two sides of the electrothermal diaphragm 1 are respectively provided with Two groups of protruding parts 7, the protruding parts 7 are arranged on the protective cover 10 of the outer contour edge of the electrothermal film 1;

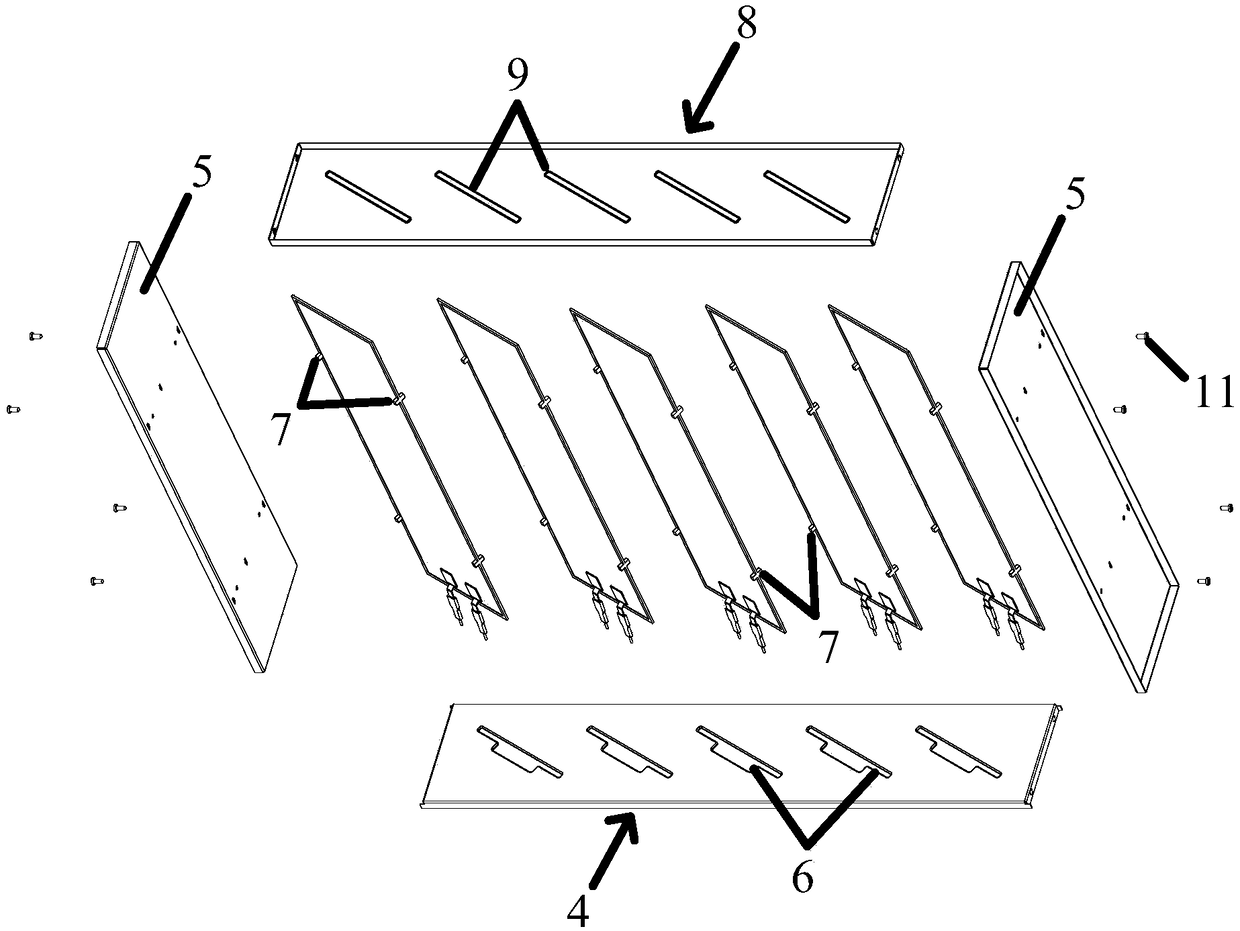

[0054] Fixture 3, such as Figure 4 As shown, it includes a first clamping beam 4 connected to the lower side of the electrothermal diaphragm 1, a second clamping beam 8 connected to the upper side of the electrothermal diaphragm 1, and a first clamping beam 8 connected to the first clamping beam respectively. The beam 4 and the second clamping beam 8 are clamped and connected to support th...

Embodiment 2

[0067] The difference between this embodiment and Embodiment 1 is that the fixed frame 3 has only one first clamping beam 4, specifically, the fixed frame 3 includes a first clamping beam that is clamped and connected to the lower side of the electrothermal diaphragm 1 4 and a supporting plate respectively connected to the first clamping beam 4 for supporting the electrothermal diaphragm 1, and the first clamping beam 4 is provided with the lower end of the electrothermal diaphragm 1 and the connecting terminal 2 through the convex-shaped first slot 6, the protruding part 7 provided on the lower side of the electrothermal film 1 abuts against the upper surface of the first clamping beam 4, and the electrothermal film 1 vertical arrangement, the electrothermal diaphragm 1 is restricted from sliding out of the first clamping beam 4 through the protrusion 7 provided on the lower side of the electrothermal diaphragm 1 by the action of gravity. The fixing work of the electrothermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com