A gas-oxygen/kerosene vortex cooling combustor

A combustion chamber and kerosene technology, which is applied in the aerospace field, can solve the problems of low combustion efficiency, carbon deposition on the wall and nozzle outlet, and small structure size, and achieves the effects of reliable ignition, reliable thermal protection, and effective thermal protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

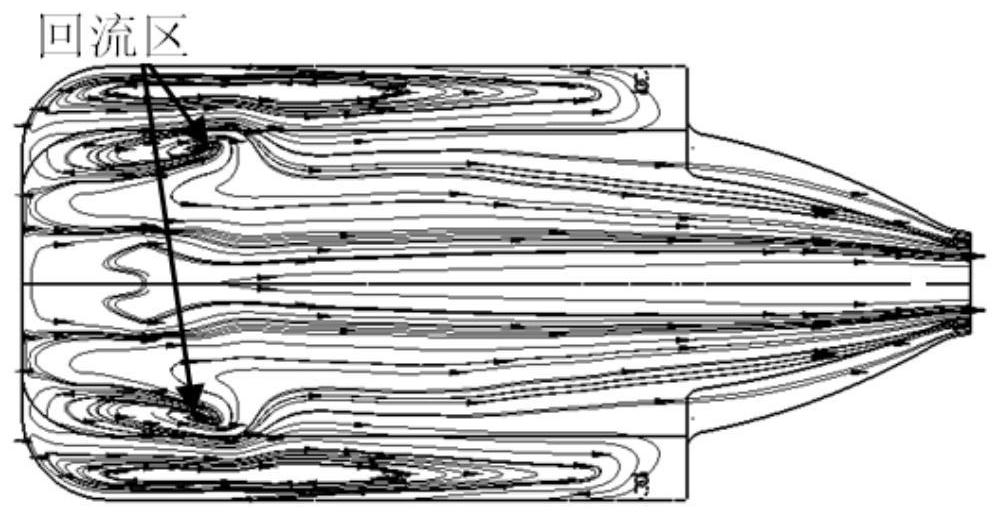

[0043] Taking 150N gas-oxygen / kerosene vortex cooling combustion chamber as an implementation case, the combustion chamber structure can be obtained through reasonable combustion chamber structure parameter matching. figure 1 Shown. Compressible ideal gas, balanced non-adiabatic PDF (probability density model) non-premixed combustion model, RNG k-ε turbulence model and discrete atomization model are used for simulation calculation verification.

[0044] The axial velocity and streamline distribution in the vortex cooling combustion chamber are as follows: figure 2 with image 3 Shown. The axial velocity in the cylindrical section of the thrust chamber has a reverse interface, which indicates that an inner and outer double vortex structure is formed in the thrust chamber; a stable low-speed recirculation zone is formed on both sides of the injection panel of the combustion chamber, which is conducive to propellant mixing and reliability Ignition, flame stability and increase comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com