Displacement assembly and variable valve lift device

A technology of valve lift and components, which is applied in the direction of valve devices, engine components, machines/engines, etc., can solve the problems of poor stability of switching valve lift, reduce the probability of interference, and reduce the process of switching valve lift. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

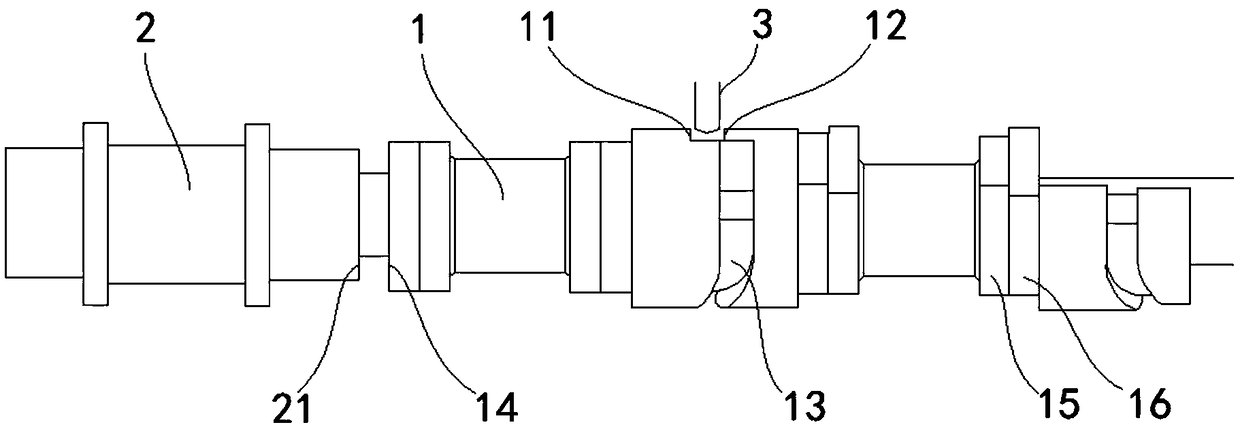

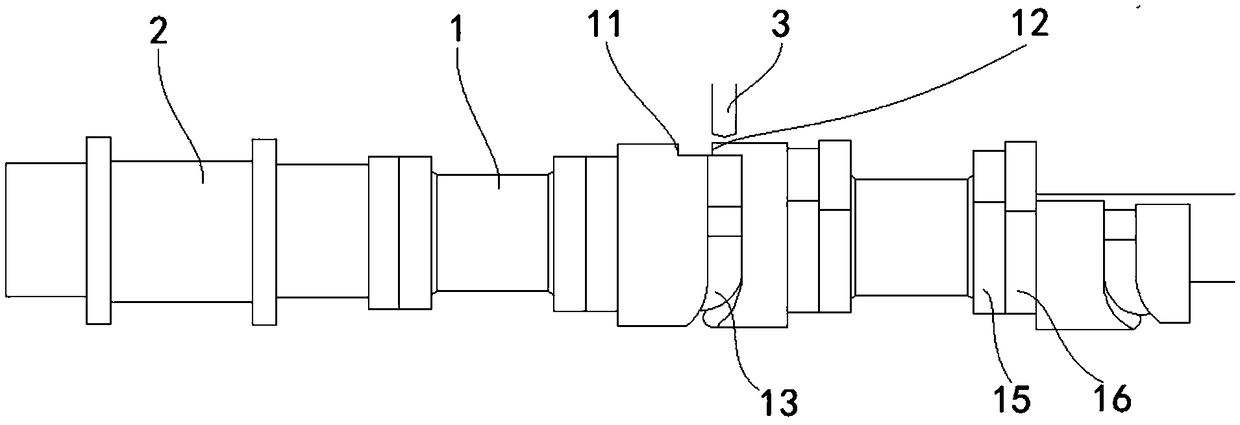

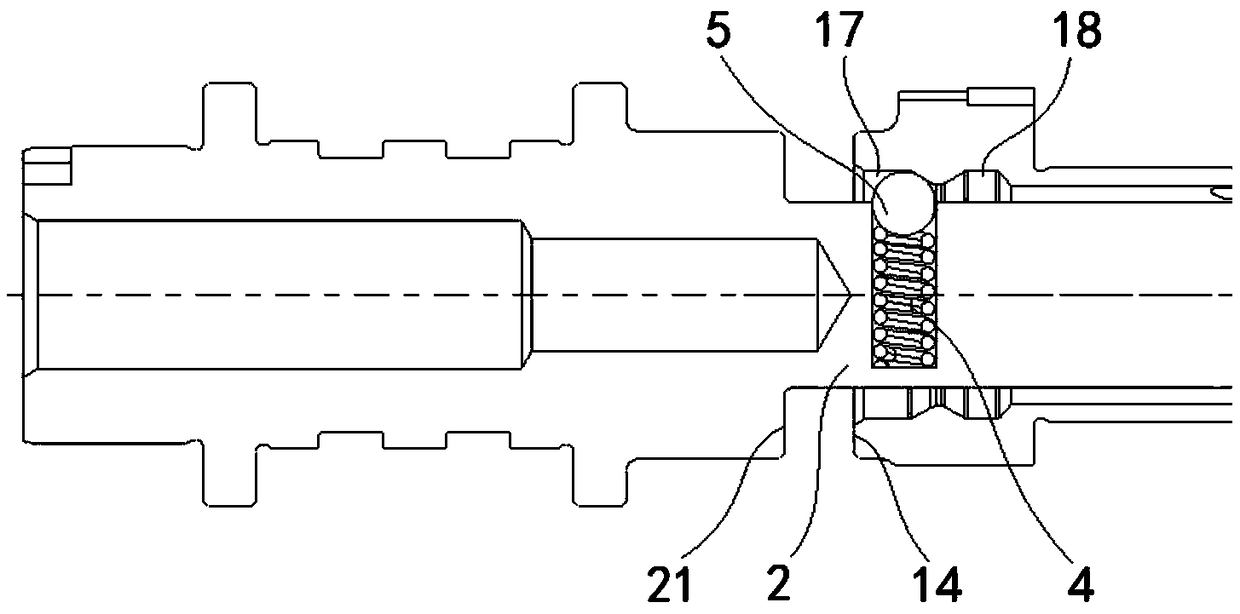

[0041] The displacement assembly provided by this embodiment, such as Figure 1 to Figure 4 As shown, including the shift sleeve 1; the outer wall of the shift sleeve 1 is provided with a groove, the groove is arranged in a spiral shape around the axis of the shift sleeve 1, and the distance between the two side walls at each end of the groove Both are greater than the distance between the two side walls in the middle of the groove.

[0042] When in use, the shift sleeve 1 is arranged on the mandrel 2, which can drive the shift sleeve 1 to rotate around the axis of the mandrel 2 when the mandrel 2 rotates. At this time, the pin shaft 3 is inserted into the groove to drive the shift The sleeve 1 moves along the axial direction of the mandrel 2, thereby driving the cam on the mandrel 2 to move to a suitable position along the axial direction of the mandrel 2, so as to adjust the valve lift. Because the width of the groove is variable, the width of the two ends of the groove is ...

Embodiment 2

[0062] The variable valve lift device provided by this embodiment, such as Figure 1 to Figure 4 As shown, it includes the mandrel 2, the executive assembly and the shifting assembly described in Embodiment 1; the shifting sleeve 1 is sleeved on the mandrel 2, and the mandrel 2 can drive the shifting sleeve 1 to rotate around the axis of the mandrel 2; The actuator assembly includes a pin shaft 3 that can extend into and out of the groove. When the pin shaft 3 extends into the groove, the pin shaft 3 can slide along the groove to drive the shift sleeve 1 to slide axially along the mandrel 2 .

[0063] When in use, the shift sleeve 1 is arranged on the mandrel 2, which can drive the shift sleeve 1 to rotate around the axis of the mandrel 2 when the mandrel 2 rotates. At this time, the pin shaft 3 is inserted into the groove to drive the shift The sleeve 1 moves along the axial direction of the mandrel 2, thereby driving the cam on the mandrel 2 to move to a suitable position al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com