Seating Buffer Type Electromagnetic Fully Variable Valve Control Method

A valve and variable technology, applied in the direction of electrical control, engine control, fuel injection control, etc., can solve problems such as the inability to restrict the valve seating speed, the difficulty of precise valve control, and the harsh working environment of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

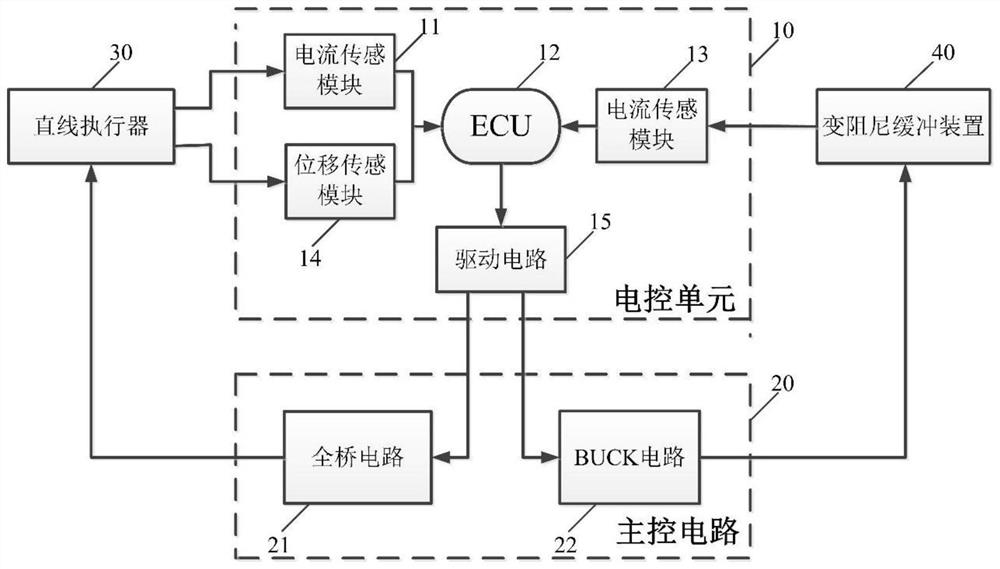

[0016] combine figure 1 , a seat buffer type electromagnetic fully variable valve control system, including a variable damping buffer device 40, an electronic control unit 10, a main control circuit 20, and a linear actuator 30.

[0017] The variable damping buffer device 40 includes a casing, a piston, a coil, and a piston rod. The magneto-rheological fluid is arranged in the casing, the piston is arranged in the casing, and the piston rod is connected to the piston and an external air valve.

[0018] The electronic control unit 10 includes an ECU12, and two current sensing modules electrically connected to the ECU12, a displacement sensing module 14 and a drive circuit 15, and the first current sensing module 13 is also connected to the coil and the solenoid valve in the variable damping buffer device 40. The second current sensing module 11 is also electrically connected to the linear actuator, and the displacement sensing module 14 is also electrically connected to the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com