High temperature and high pressure visualization wellbore gas-liquid flow state simulation experiment device and method

A simulation experiment device, high temperature and high pressure technology, used in earthwork drilling, wellbore/well components, measurement, etc., can solve the problems of not installing heating and heat preservation device, not having, not simulating multiphase pipe flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

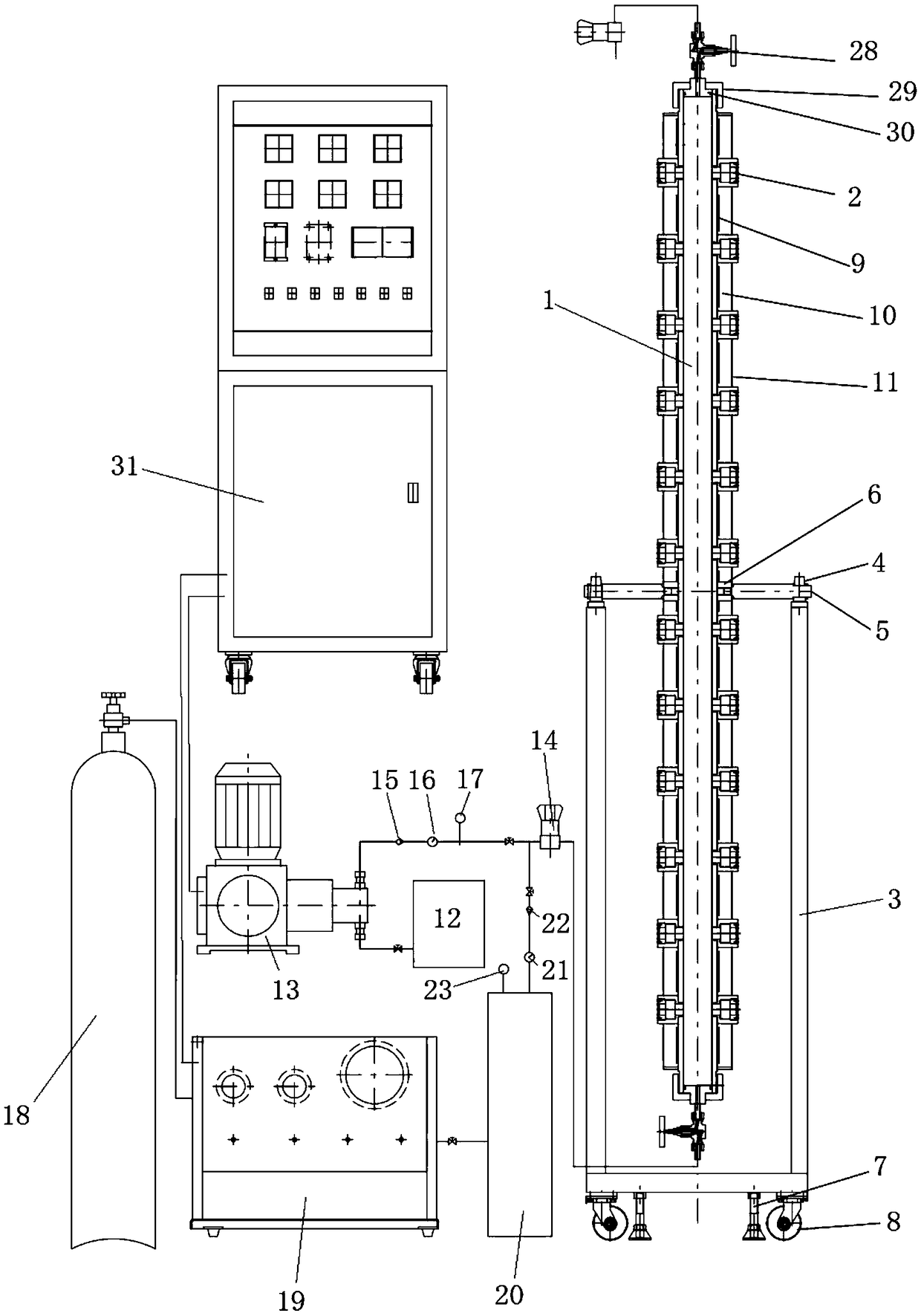

[0044] A high-temperature and high-pressure visualization wellbore gas-liquid flow state simulation experiment device includes a wellbore system and a gas-water pressurized injection system.

[0045] The wellbore system includes a wellbore model and a model bracket. The model bracket is used to fix and support the wellbore model. The wellbore model is provided with a high-pressure visible window. The outside of the wellbore model is provided with a heating and insulating layer. The heating and insulating layer is used for heating and insulating the wellbore model.

[0046] The gas-water pressurized injection system includes a liquid pressurized injection device and a gas pressurized injection device. Both the liquid pressurized injection device and the gas pressurized injection device are connected to the wellbore model through high-pressure pipelines. The liquid pressurized injection device is used to inject liquid into In the wellbore model, the gas pressurized injection devi...

Embodiment 2

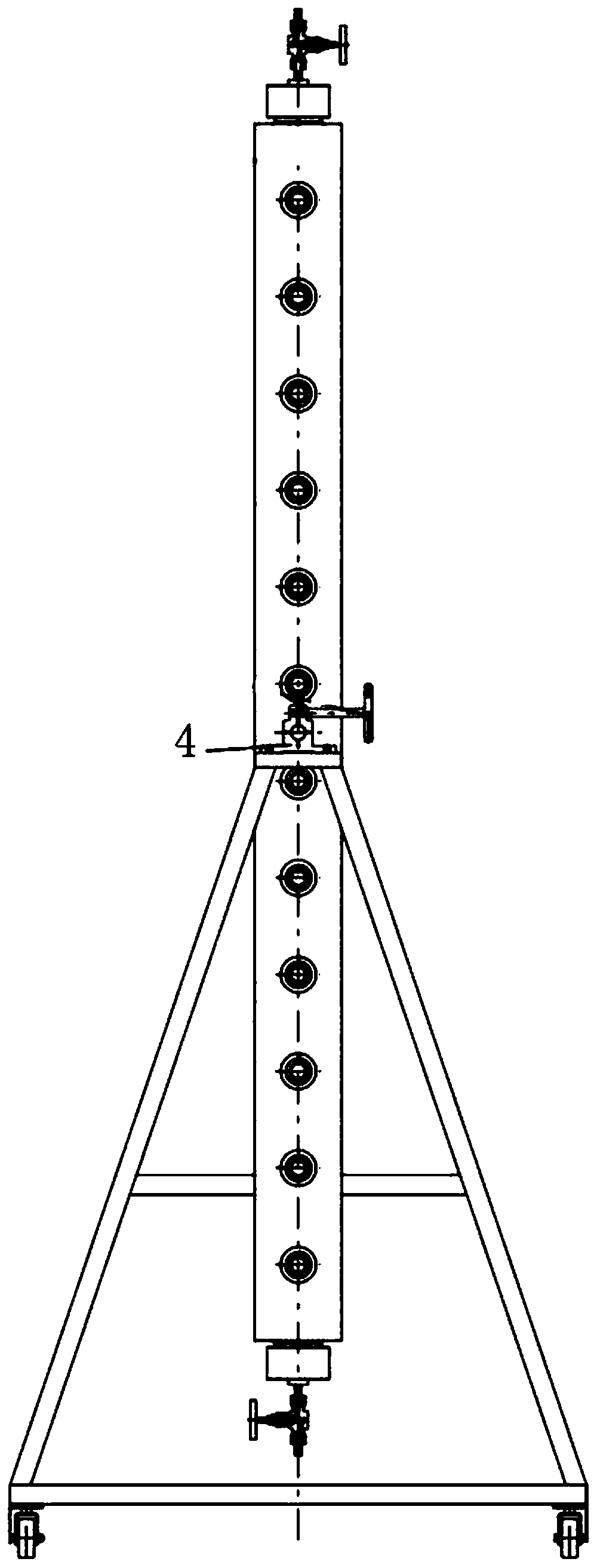

[0048] A high-temperature and high-pressure visualization wellbore gas-liquid flow state simulation experiment device, the structure of which is described in Example 1, the difference is that the model support includes two stands, the top of the two stands is equipped with a bearing seat, and two bearings There is a support shaft on the seat, which is connected with the outer wall of the shaft model through a support ring; the bottom of the stand is equipped with lifting feet and casters, the casters are used to drive the movement of the entire shaft system, and the lifting feet are used for fixed-point fixing. The wellbore model can rotate with the space of the support shaft, and the wellbore conditions from vertical to horizontal and at any angle in the middle can be simulated through this bracket. The wellbore model is a cylindrical model with an inner diameter of 76mm and a height of 300cm, and the wellbore model is made of stainless steel. The top of the wellbore model is...

Embodiment 3

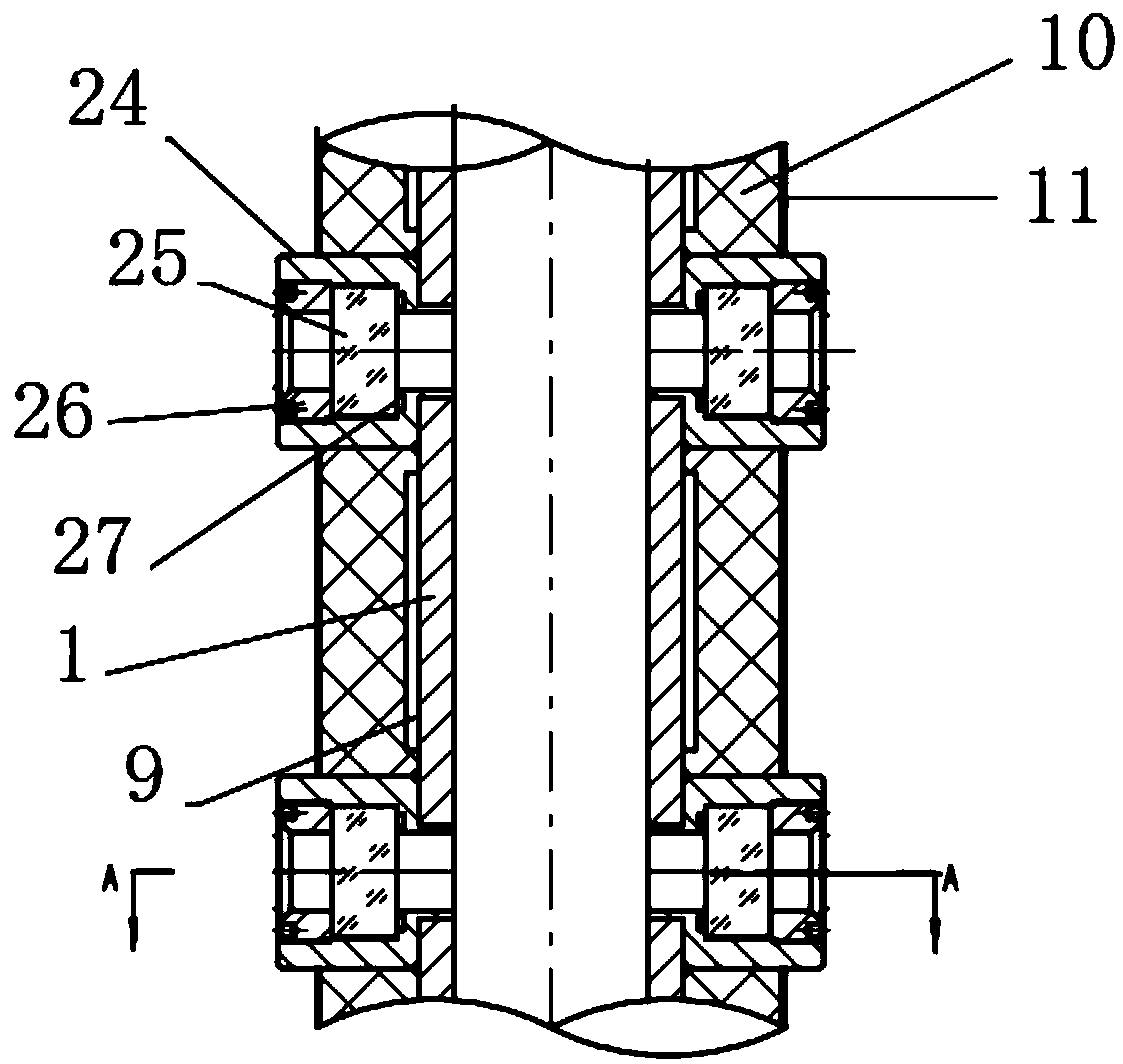

[0050] A high-temperature and high-pressure visualization wellbore gas-liquid flow state simulation experiment device, the structure of which is described in Example 2, the difference is that the high-pressure visible window includes a window, a high-pressure glass, and a pressure ring, such as image 3 , Figure 4 As shown, the viewing window and the wellbore model are penetrated through the through-hole, and there is a gasket between the high-pressure glass and the through-hole, and a pressure ring is provided outside the high-pressure glass, which is used to fix the high-pressure glass; The pressure resistance of high pressure glass is 30MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com