Double-wall drill pipe

A double-wall drill pipe and short-circuit technology, which is used in drill pipe, drill pipe, earth-moving drilling, etc., can solve the problems of reducing the service life of the sealing ring, damage to the sealing ring of the sealing ring, squeezing, etc., and improve the sealing pressure. Capability and reliability, seal pressure rating and reliability improvement, effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

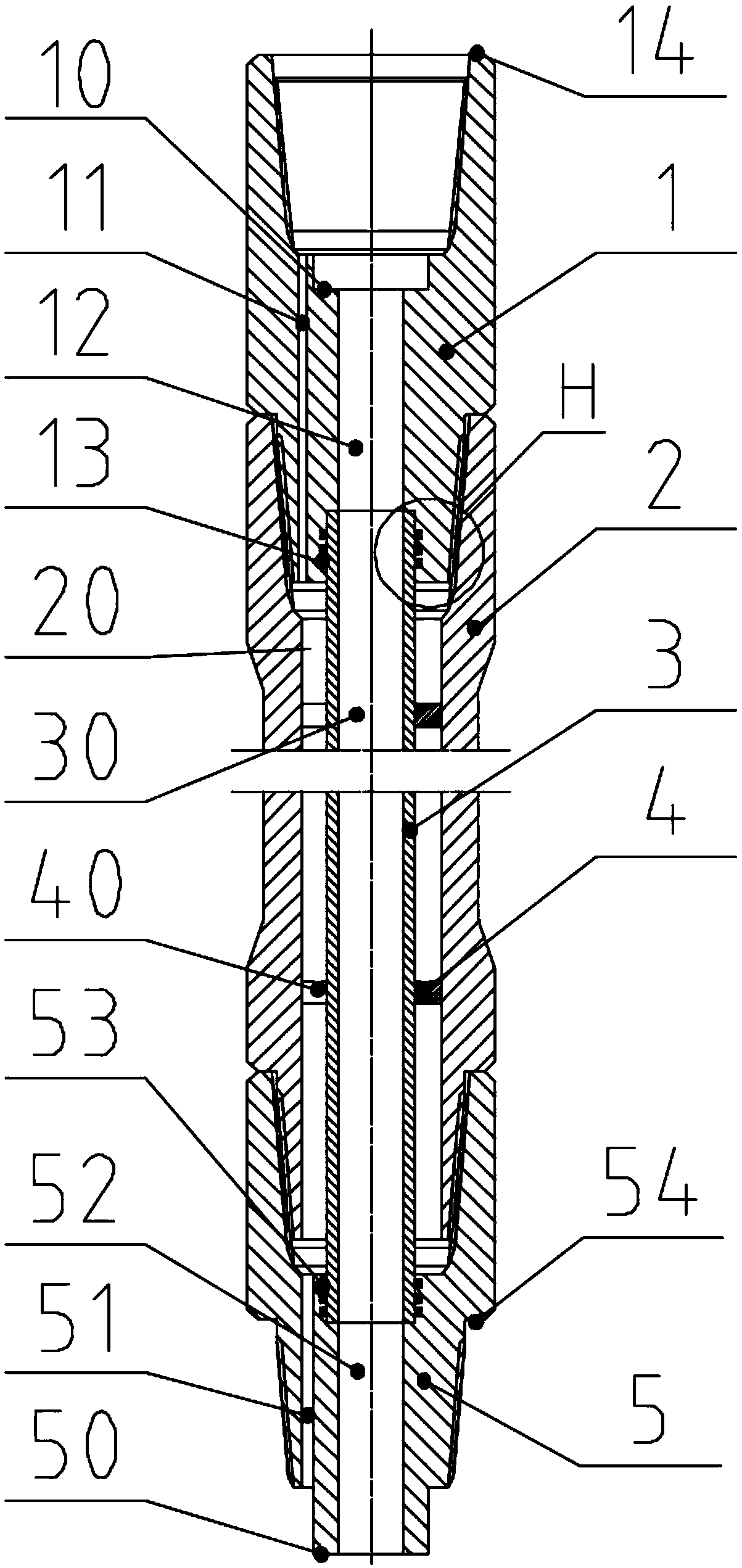

[0038] Such as figure 1 As shown, the double-walled drill pipe includes an upper short connection 1, an outer pipe 2 and a lower short connection 5 sequentially connected from top to bottom, and an inner pipe 3 sleeved in the center hole of the outer pipe 2; wherein,

[0039] The upper short connection 1 is a cylindrical structure, the inner wall of the top end is processed with an internal thread concentric with the outer cylindrical surface, the outer wall of the bottom end is processed with an outer thread concentric with the outer cylindrical surface, and the end surface located below the internal thread is respectively along the In the axial direction, there are a central channel A12 and an eccentric channel A11 that penetrate up and down;

[0040] The outer pipe 2 is a conventional single-wall drill pipe, with internal threads processed on the inner wall of the top end and external threads processed on the outer wall of the bottom end; The threads cooperate with each ot...

Embodiment 2

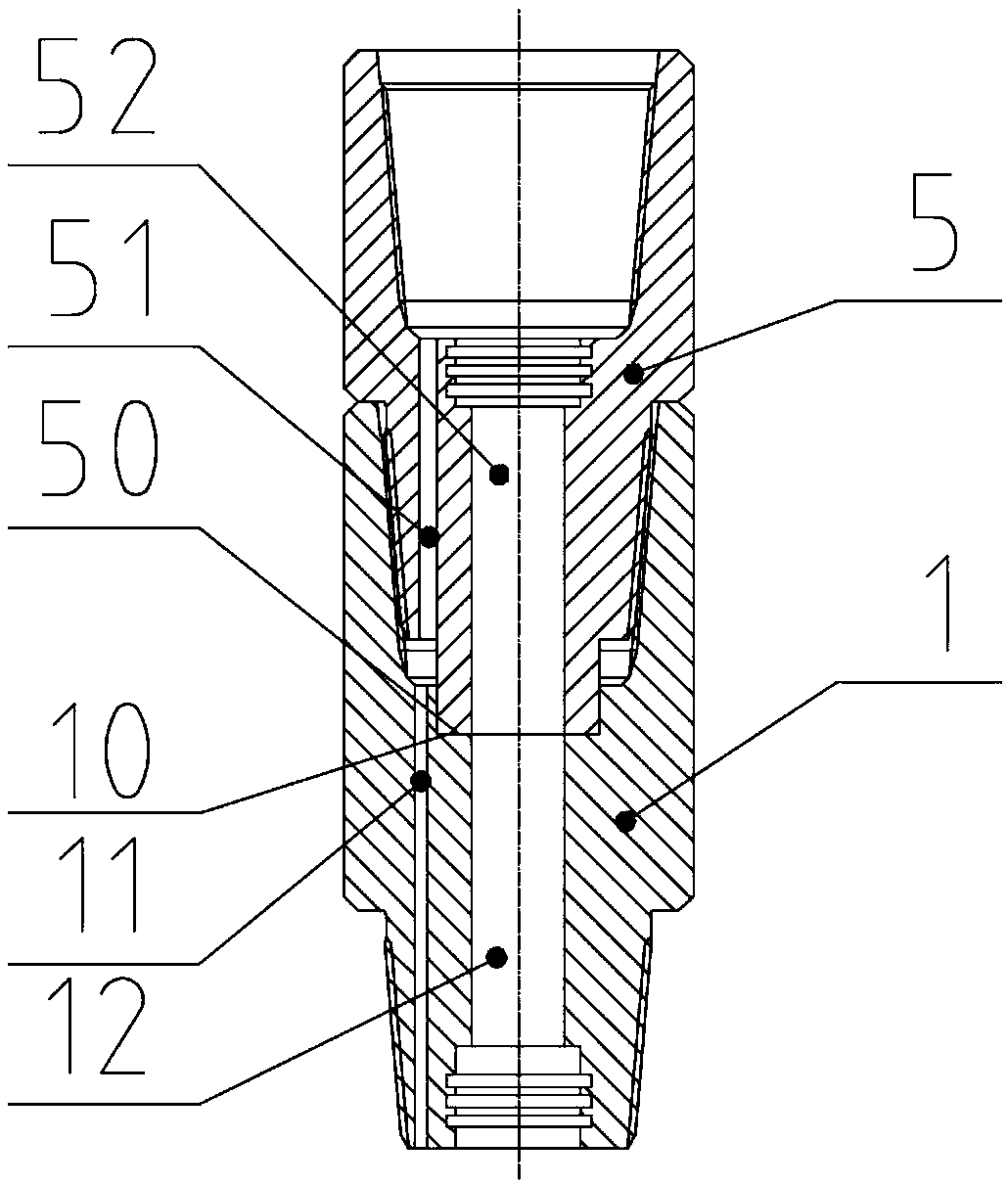

[0047] Such as image 3 As shown, the structure of the double-walled drill rod is basically the same as that of the double-walled drill rod in Example 1, the difference is that: between the shoulder surface B10 and the shoulder surface D50 of the upper short-circuit 1 is provided with a The seal C60 adapted to the shoulder surface 50 makes the seal between the shoulder surface B10 and the shoulder surface D50 form a seal through the seal C60; wherein, the seal C60 is a combined sealing gasket that is vulcanized by rubber and metal ring .

Embodiment 3

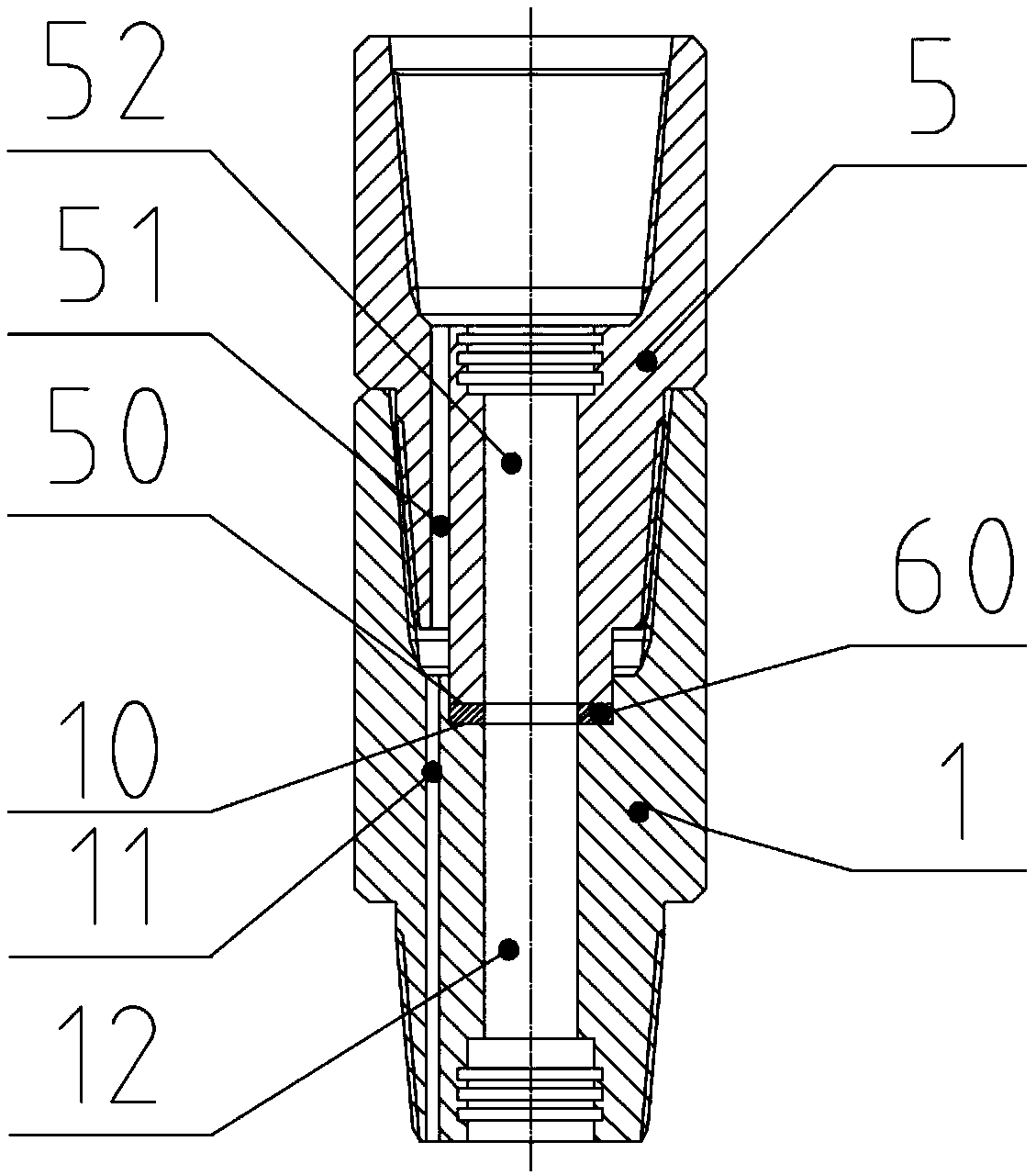

[0049] Such as Figure 4 As shown, the structure of the double-walled drill pipe is basically the same as that of the double-walled drill pipe in Example 1, except that the end face located below the internal thread of the upper joint 1 is processed as a platform that cooperates with the annular shoulder surface D50 Shoulder surface B10, and an annular groove with a rectangular ring cross section is opened on the shoulder surface B10, and a rectangular sealing ring C60 is arranged in the annular groove, so that the rectangular sealing ring passes between the shoulder surface B10 and the shoulder surface D50 A seal is formed; wherein, the rectangular sealing ring is a rectangular rubber ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com