Automatic portal crane grab unloading system

A portal crane, automatic unloading technology, applied in the direction of load hanging components, transportation and packaging, safety devices, etc., can solve the problems of large weight difference, rigid grasping, unable to grasp weight detection, etc., to ensure safety. the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

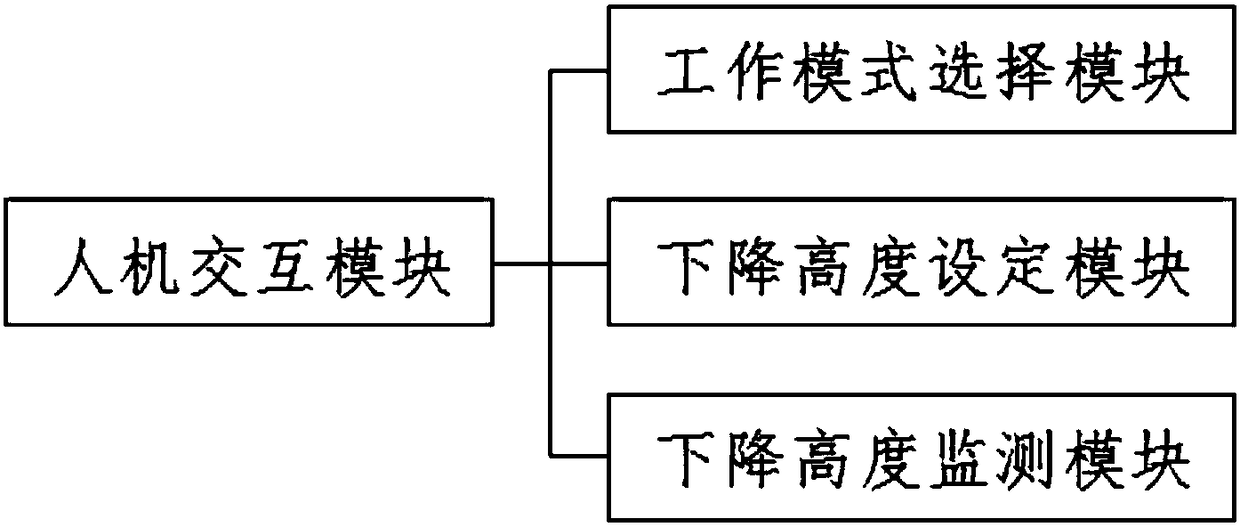

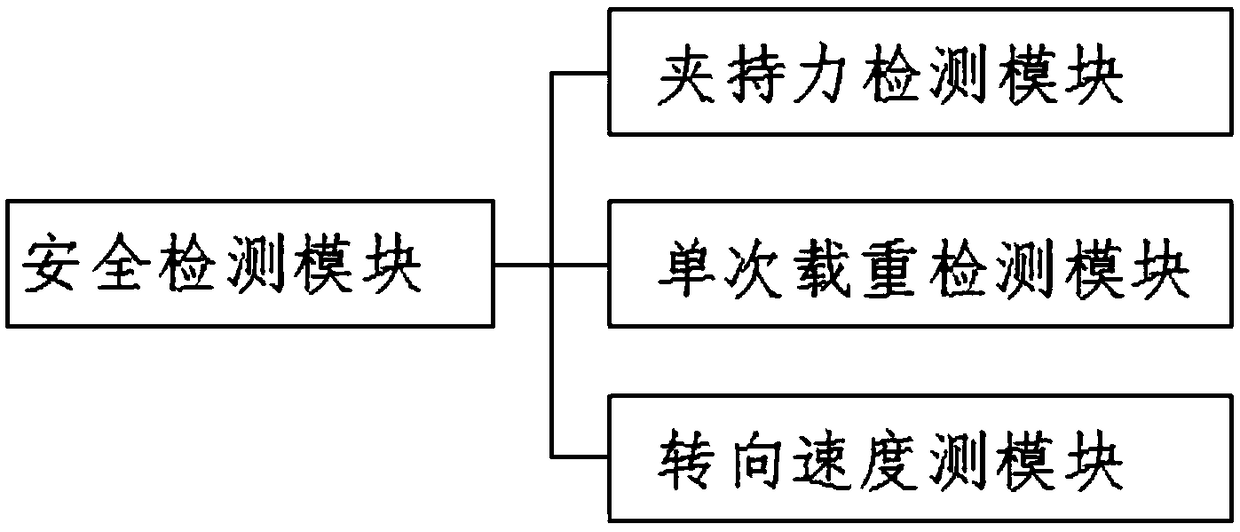

[0017] see Figure 1~3 , in an embodiment of the present invention, a grab bucket automatic unloading system for a portal crane includes a controller, a distance measuring module, a supporting machine control motor, an opening and closing machine control motor, and a human-computer interaction module. The distance measuring module is set at On the beam of the gantry crane, including the cargo pile distance detection module and the grab distance detection module, the distance measurement module, the support machine control motor, the opening and closing machine control motor and the human-computer interaction module are all connected to the controller, and the controller is supported through the control The machine controls the motor to drive the movement of the support rope, and the controller controls the motor to drive the movement of the opening and closing rope by controlling the opening and closing machine. The human-computer interaction module includes a working mode sele...

Embodiment 2

[0027] The difference from Embodiment 1 is that the controller is also electrically connected with an infrared sensor and a voice prompt module. When someone is detected around the infrared sensor, the controller will control the voice prompt module to work, thereby sending a leave signal to the surrounding people , further improving the security of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com