A novel multi-bead watch strap assembly tooling and an assembly method thereof

A technology for assembling tooling and watch straps, which is applied in the field of new multi-bead watch strap assembling tooling and assembly, can solve the problems of double tooth branch bending and uneven force on double tooth branch, and achieve small matching error, low repair rate, and guaranteed The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] For example, the model is a five-bead watch strap, made of 316L stainless steel, the main accessories are left bead 310, right bead 320, middle bead I330, middle bead II340, double tooth branch 400, single section 35 pieces, body part 20 pieces, body part Composition of 15 capsules.

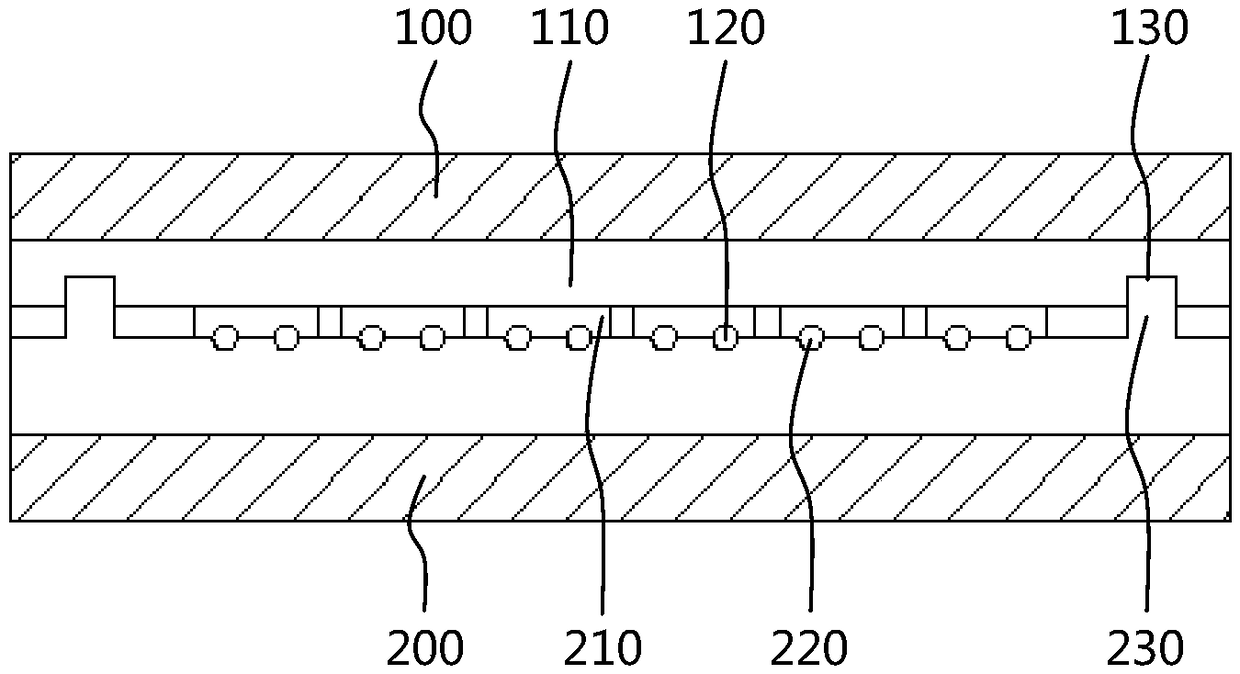

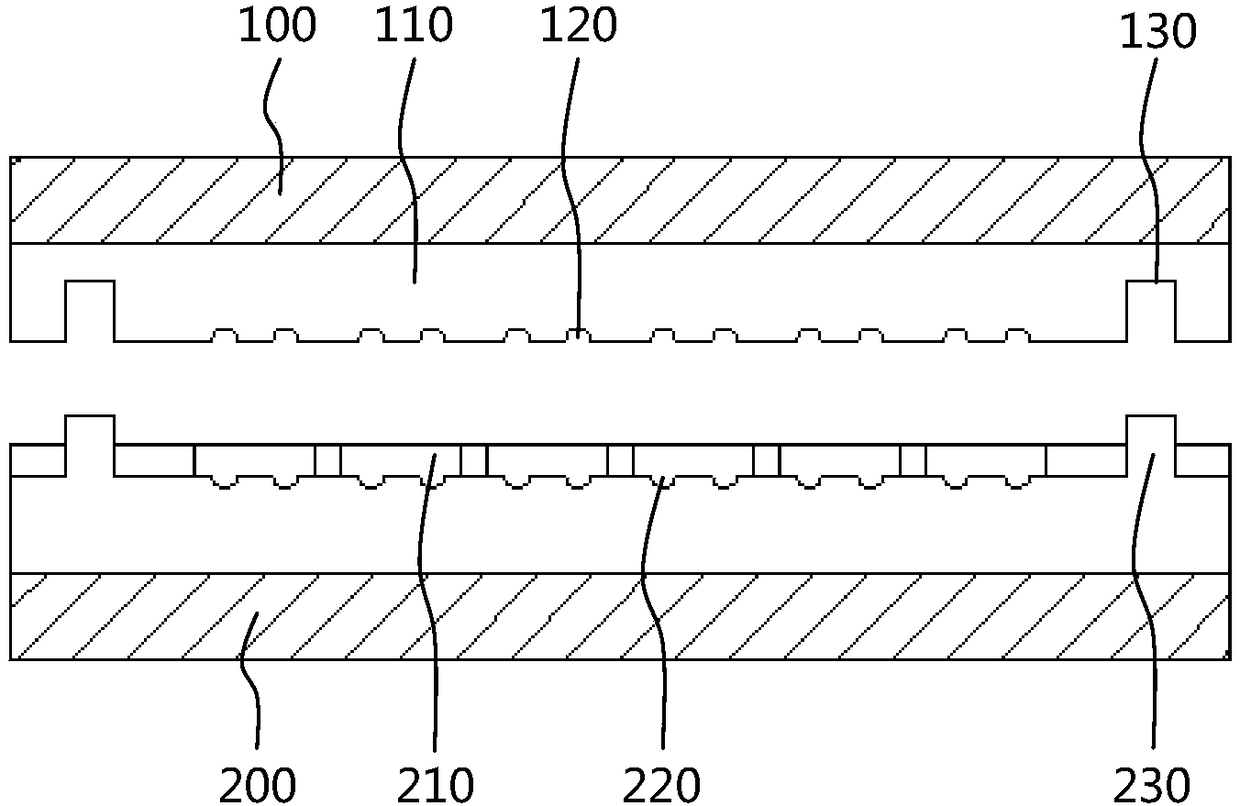

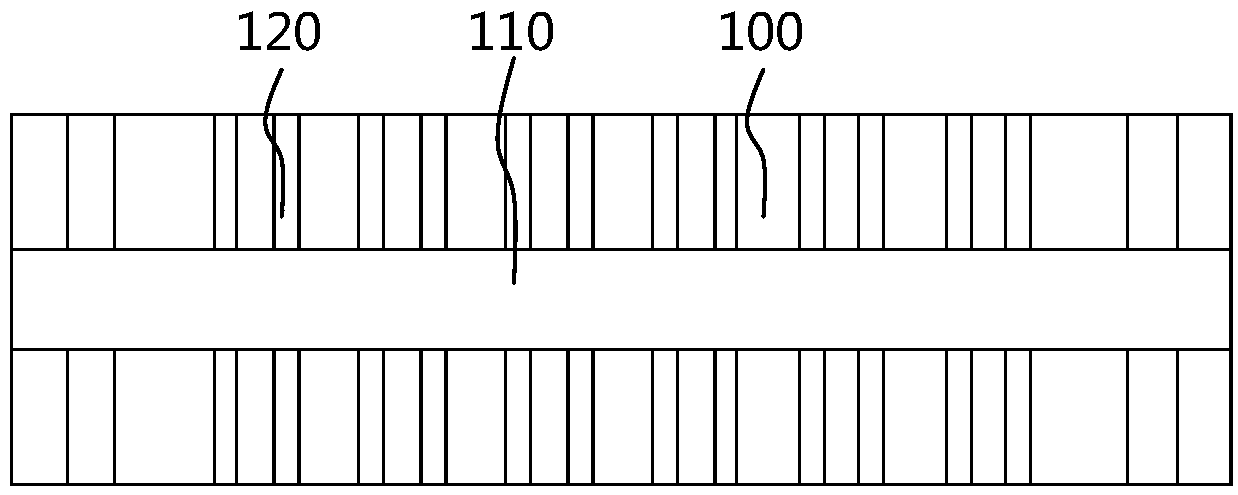

[0041] Such as Figure 1 to Figure 7 As shown, a new type of multi-bead watchband assembly tooling in this embodiment includes an upper mold 100 and a lower mold 200. The lower mold 200 is provided with six accommodation cavities 210 along the transverse central axis. The structural shape of the accommodation cavities 210 is similar to that of the beads (the left bead or the right bead) the structural shapes are matched, the accommodation cavity 210 is provided with twelve first circular grooves 220 along the longitudinal side, and each accommodation cavity 210 is assigned two first circular grooves 220, each first circular groove A double tooth branch 400 can be placed in the groove 220;...

Embodiment 2

[0048] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the cross-sectional shape of the through groove 110 is rectangular. Therefore, in order to facilitate demoulding of the watch bead, the width of the through groove 110 is greater than the width of the accommodating cavity 210 .

Embodiment 3

[0050] This embodiment provides a novel multi-bead strap assembly method, including the following specific steps:

[0051] Step S101, first put the double-tooth stick 400 into the lubricating oil and soak for 2-5 minutes, the optimal soaking time is 3 minutes, the lubricating oil can completely soak the entire end of the double-tooth stick 400, which can reduce the assembly time. Resistance; the lubricating oil is cutting lubricating oil, such as JQ-1 precision cutting lubricating oil commonly used in the market, etc., but not limited to the lubricating oil listed above;

[0052] Step S102, put the left bead 310 / right bead 320 of the multi-bead watchband to be assembled in the accommodating cavity 210 of the corresponding lower mold 200 according to the distinction between the bottom and the surface, and place the double tooth branch 400 according to the first position of the lower mold 200. The round groove 220 is placed flat, then the upper mold 100 and the lower mold 200 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com