High-yield two-product mixed maghemite beneficiation process

A high-yield, high-quality technology, applied in the field of hematite mixed iron ore beneficiation process, can solve the problem of low recovery of all iron, and achieve the effects of avoiding pollution, ensuring recovery rate, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

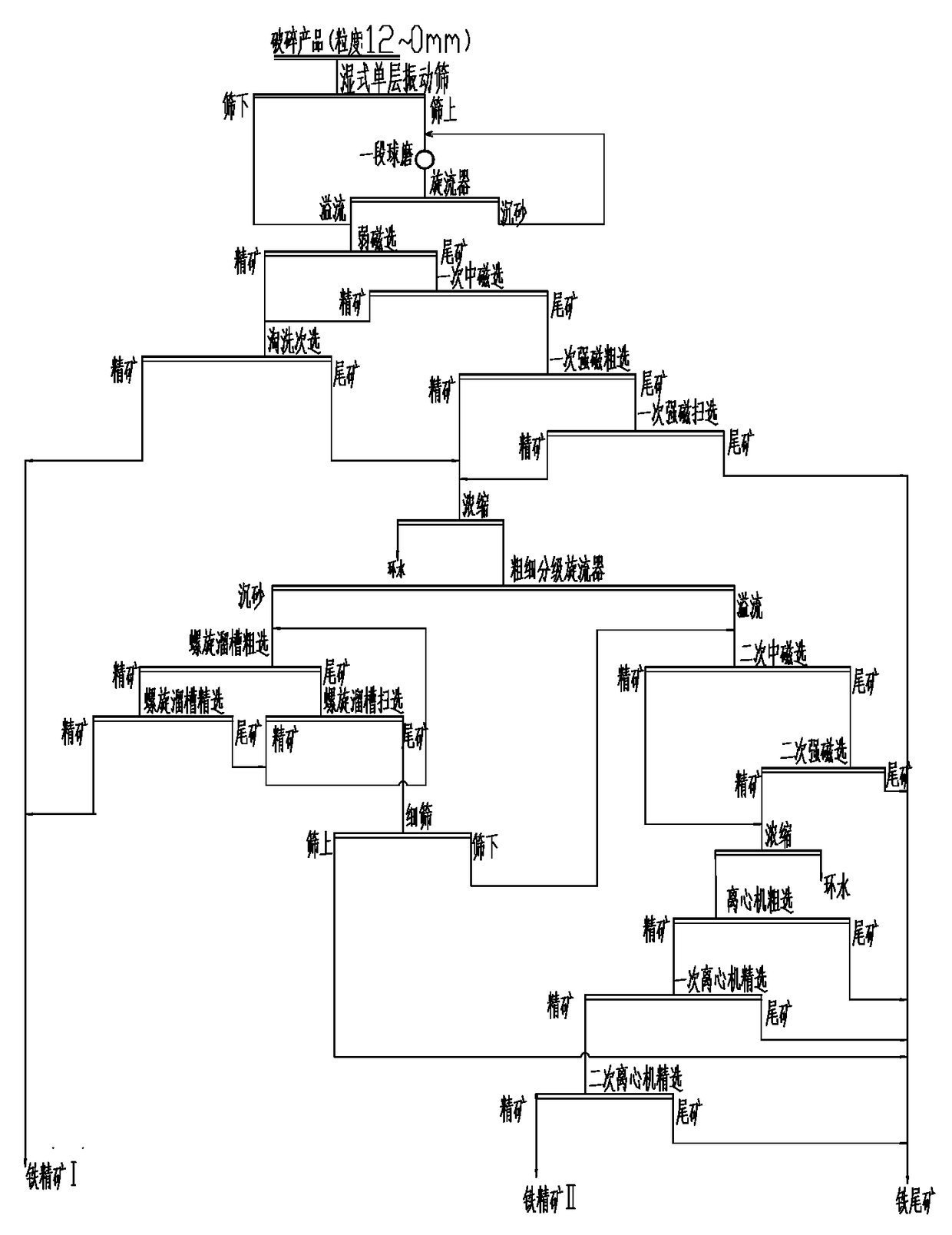

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] Such as figure 1 As shown, a high-yield two-product hematite ore beneficiation process of the present invention includes that the iron grade is 41.8%, and the hematite with a slime content of 30% in the raw ore is subjected to coarse crushing, medium crushing and fine crushing The three-stage crushing, the raw ore and mineral types include hematite, false hematite, limonite, goethite and part of magnetite, is characterized in that it also includes the following steps: screening operation and a ball mill- A section of closed-circuit grinding operation composed of cyclone, primary magnetic separation operation, coarse and fine classification operation, gravity separation operation, secondary magnetic separation operation and centrifugation operation; the primary magnetic separation operation processes the overflow product and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com