Two-axis anti-shaking pan-tilt and camera device

An anti-shake and pan-tilt technology, applied in the field of photography, can solve problems such as limiting the anti-shake angle and not being suitable for the pan-tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

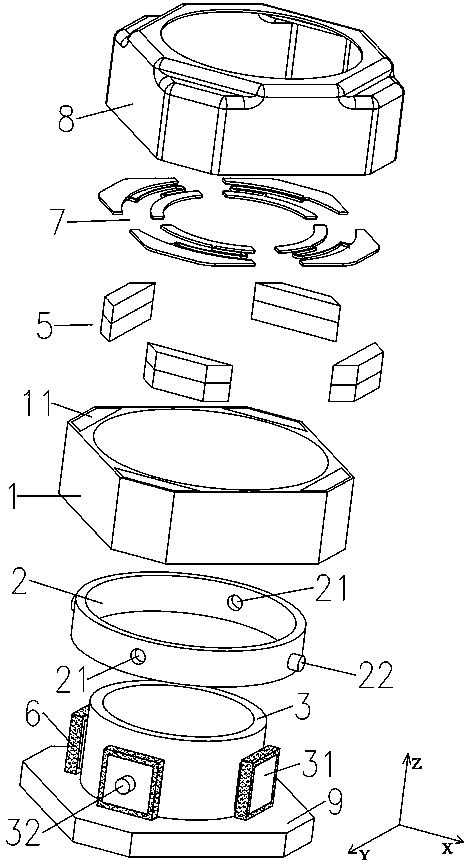

[0029] Such as Figure 2-4 As shown, a two-axis anti-shake head includes an outer bracket 1, a middle bracket 2 and an inner bracket 3 arranged sequentially from outside to inside, wherein

[0030] The outer bracket 1 is used as a fixing part and is provided with a first magnetic element group;

[0031] The middle bracket 2 is used as a rotating part around the X axis, and is pivotally connected to the outer bracket 1;

[0032] The inner bracket 3 is used as a rotating member around the Y axis and a carrier of the camera module 4, and is axially connected to the middle bracket 2, and is provided with a first magnetic element group;

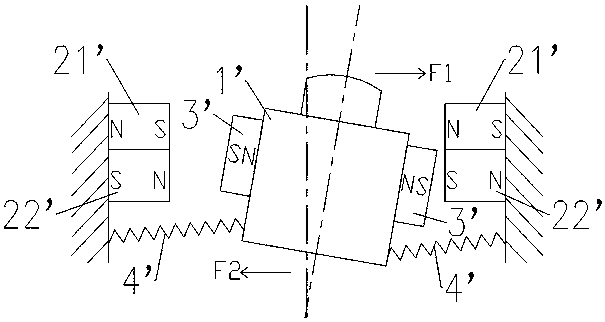

[0033] The magnetic field interaction force between the first magnetic element group and the second magnetic element group drives the middle bracket 2 to rotate around the X axis relative to the outer bracket 1, and drives the inner bracket 3 to rotate relative to the outer bracket 1 The middle bracket 2 rotates around the Y axis, and the orthog...

Embodiment 2

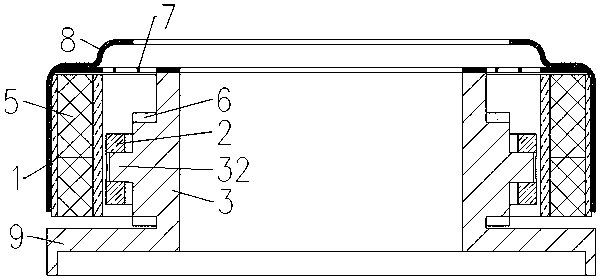

[0044] Such as Figure 5 As shown, a camera device includes the two-axis anti-shake pan-tilt described in Embodiment 1 and a camera module 4 , and the camera module 4 is assembled in the inner bracket 3 .

[0045] Specifically, the camera module 4 includes a lens 41 and a PCB 43 equipped with a photosensitive chip 42, the lens 41 is arranged on the cylindrical interior of the inner support 3, and the PCB 43 is arranged on the On the back side of the base 9 at the lower end of the inner support 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com