Physics teaching tool for demonstration of horizontal projectile motion

A technology of flat throwing and movement, applied in the field of physical teaching aids for flat throwing movement demonstration, can solve problems such as simplicity, impact on teaching quality, and incomplete demonstration effects, and achieve the effect of ensuring teaching quality and comprehensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

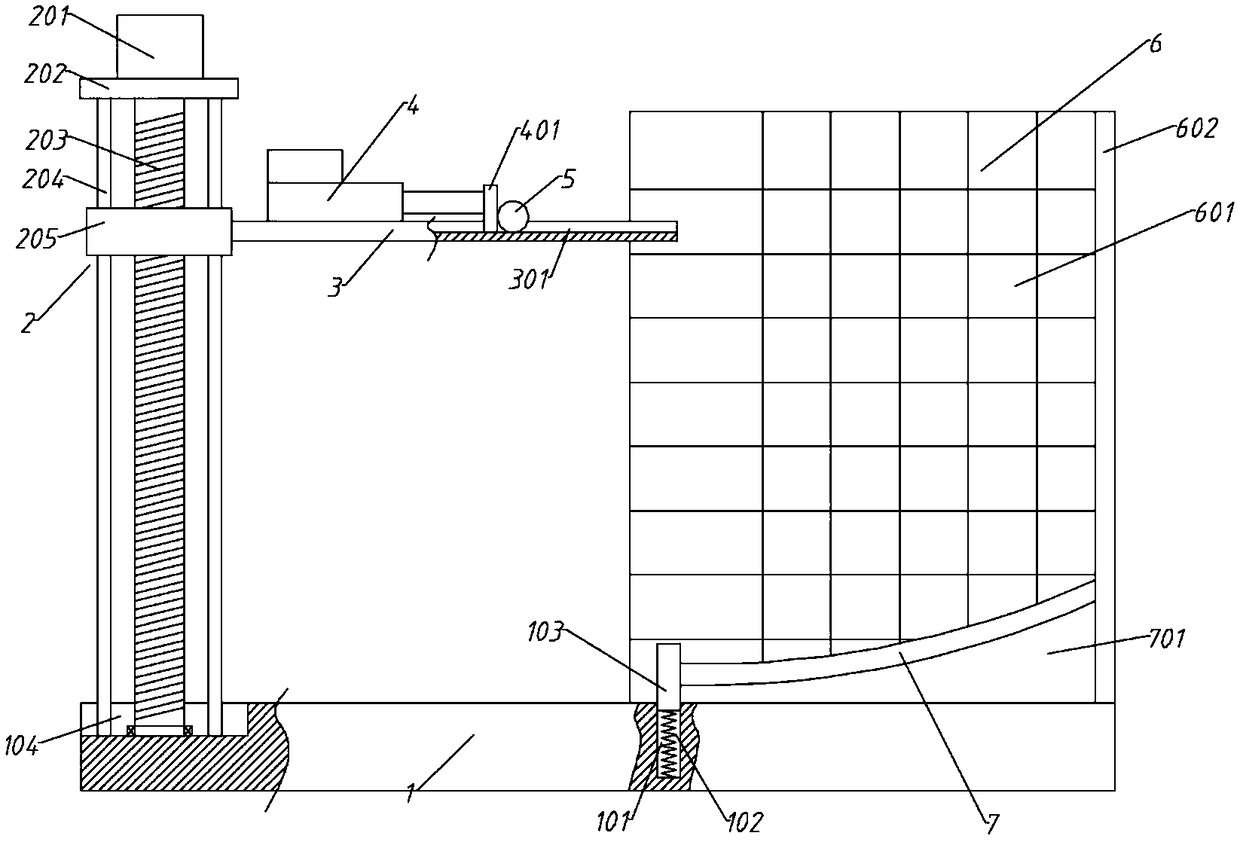

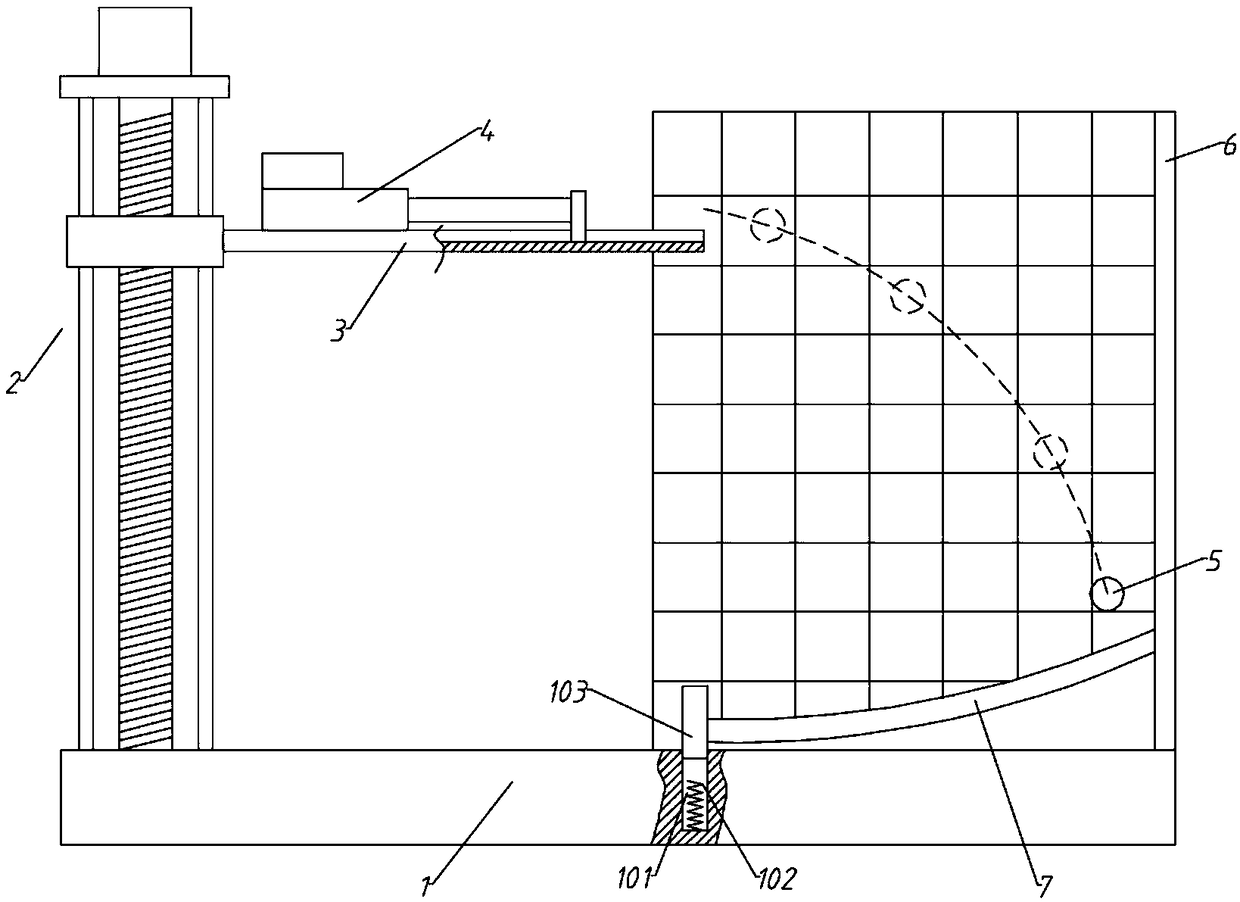

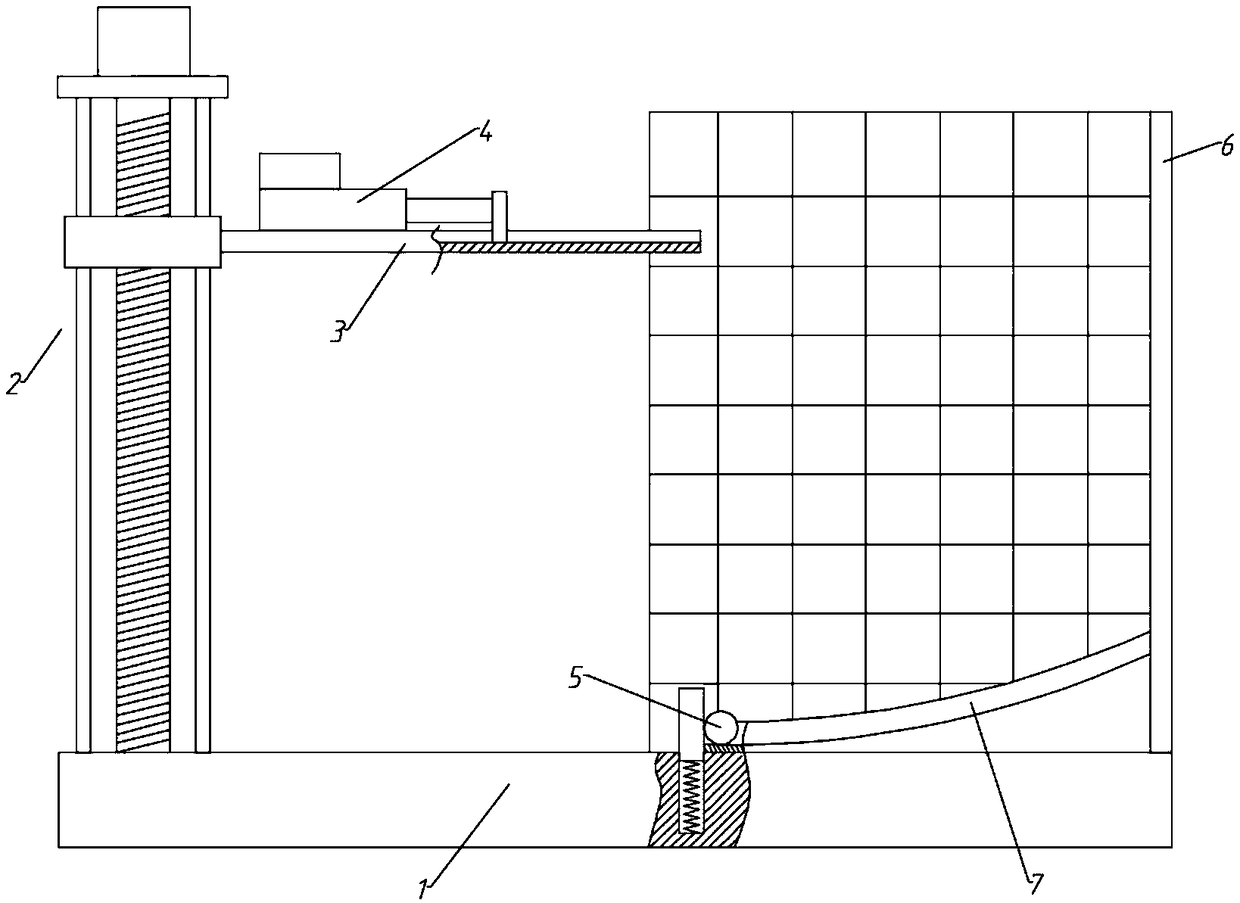

[0042] A physical teaching aid for electromagnetic induction demonstration, comprising a base 1, a lifting component 2, a flat throwing component and a demonstration board 6;

[0043] The lifting assembly 2 is arranged on the left end of the base 1, the flat throwing assembly includes a transverse plate 3, an electric push rod 4 and a No. 1 ball 5, the left end of the transverse plate 3 is connected to the lifting assembly 2, and a horizontal slideway 301 is arranged on the transverse plate 3, The electric push rod 4 is arranged on the left end of the horizontal slideway 301, and the telescopic end of the electric pushrod 4 stretches out to the right and is connected with a push plate 401. The No. 1 ball 5 is arranged in the horizontal slideway 301, and the push plate 401 pushes the small ball along the horizontal slideway 301. Horizontal slideway 301 moves;

[0044] The demonstration board 6 is arranged on the right end of the base 1, the demonstration board 6 is provided wit...

Embodiment 2

[0049] The difference from Embodiment 1 is that the lifting assembly 2 includes a driving motor 201, a top plate 202, a screw mandrel 203, a moving nut 205 and a guide rod 204. The top plate 202 is arranged above the left end of the base 1 and fixed by the vertical guide rod 204 Connected to the left end of the base 1, the driving motor 201 is arranged on the top plate 202, the output shaft of the driving motor 201 protrudes downwards and connects to the screw rod 203, the bottom end of the screw rod 203 is connected to the base 1 by rotation, and the moving nut 205 is screwed on the screw rod 203 And it is passed by the guide rod 204, and the left end of the transverse plate 3 is connected with a moving nut 205.

[0050] Utilizing the movement characteristics of the screw rod 203, the vertical movement of the horizontal plate 3 is realized, and the initial height and initial speed of the No. 1 ball 5 are conveniently adjusted.

Embodiment 3

[0052] The difference from Embodiment 2 is that the left end of the base 1 is provided with a groove 104 , and the bottom end of the lifting assembly 2 is arranged in the groove 104 to ensure the movement range of the transverse plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com