Acoustic pressure signal channel structure

A technology of channel structure and sound pressure signal, which is used in material analysis, measuring devices, instruments, etc. by optical means, can solve the problems of weak signals and inability to collect, and achieves the goal of reducing interference, facilitating the collection of weak signals, and avoiding effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

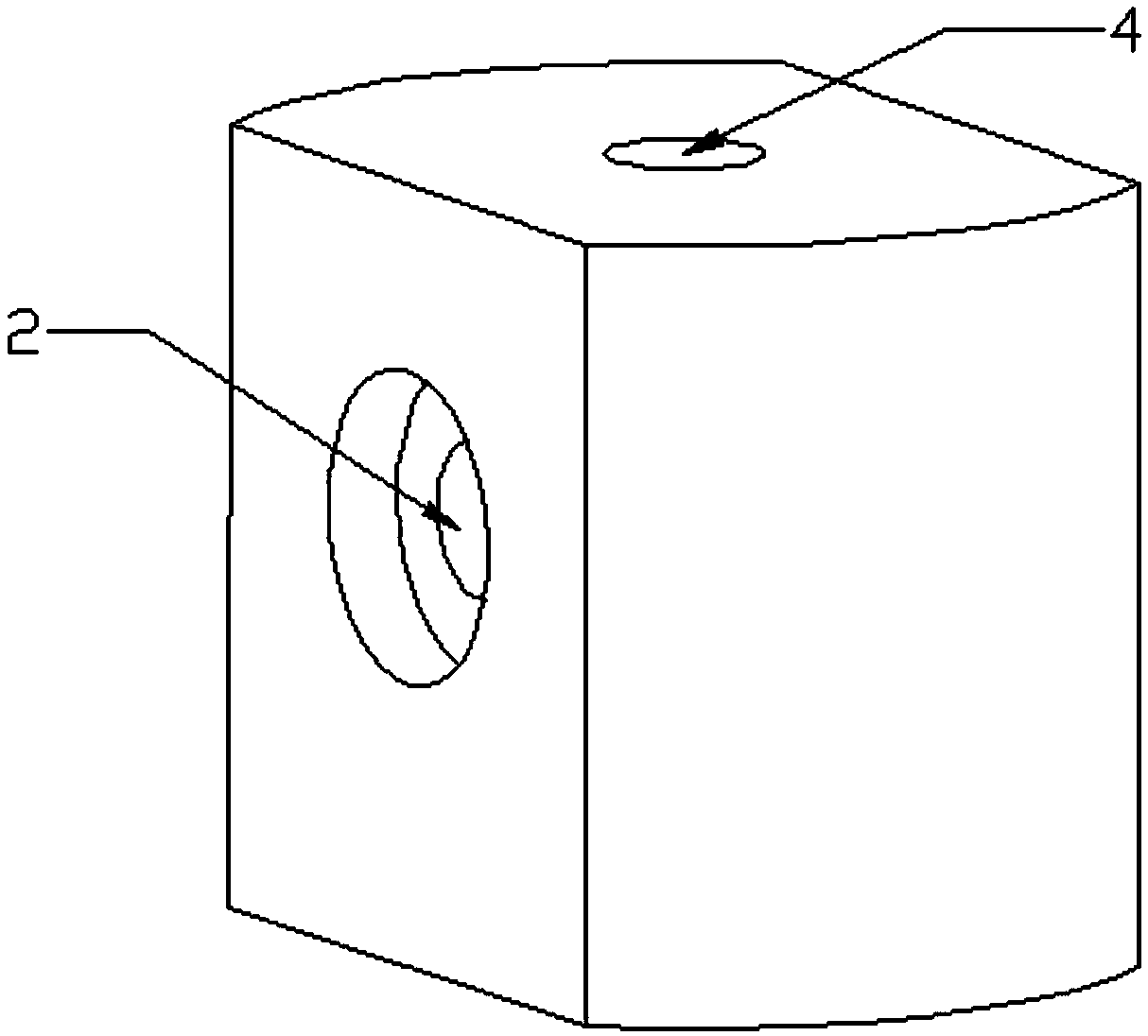

[0014] like figure 1 and figure 2 As shown, a sound pressure signal channel structure includes a channel body 1, a cavity 2 and a microphone 4 are arranged in the channel body 1, an incident window 21 is arranged at one end of the cavity 2, and the other end of the cavity 2 is A collection channel 3 is arranged between the microphones 4 , the cavity 2 includes a sample cell 22 and a conversion cell 23 , the incident window 21 is arranged at one end of the sample cell 22 , and the conversion cell 23 is connected to the sample cell 22 and is arranged at the end of the sample cell 22 . another side. The collection channel 3 is connected to the collection port of the microphone 4 , and the cavity 2 is communicated with the collection port through the collection channel 3 . Further, the collection channel 3 is a microporous channel with a diameter of 1MM, the collection channel ensures sufficient smoothness, and the air pressure is not easily lost in the collection channel 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com