Liquid application device and method for liquid-filling jointed rock mass sample for flange type SHPB(split Hopkinson pressure bar)

A technology for applying device and jointing rock mass, which is applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of not being able to observe the dynamic change process well, affecting the effect of rock dynamics test, poor sealing effect at the contact point, etc. The effect of preventing liquid leakage, diversification of types, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

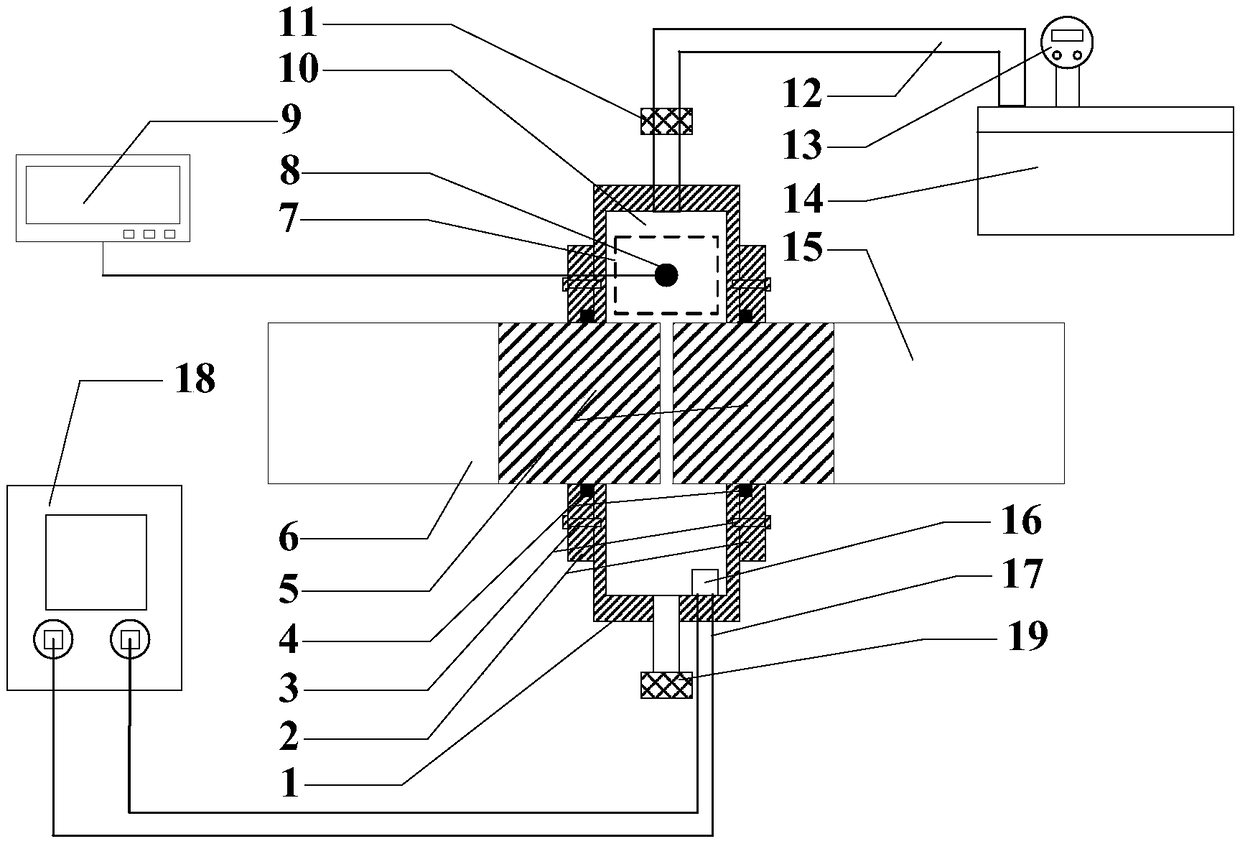

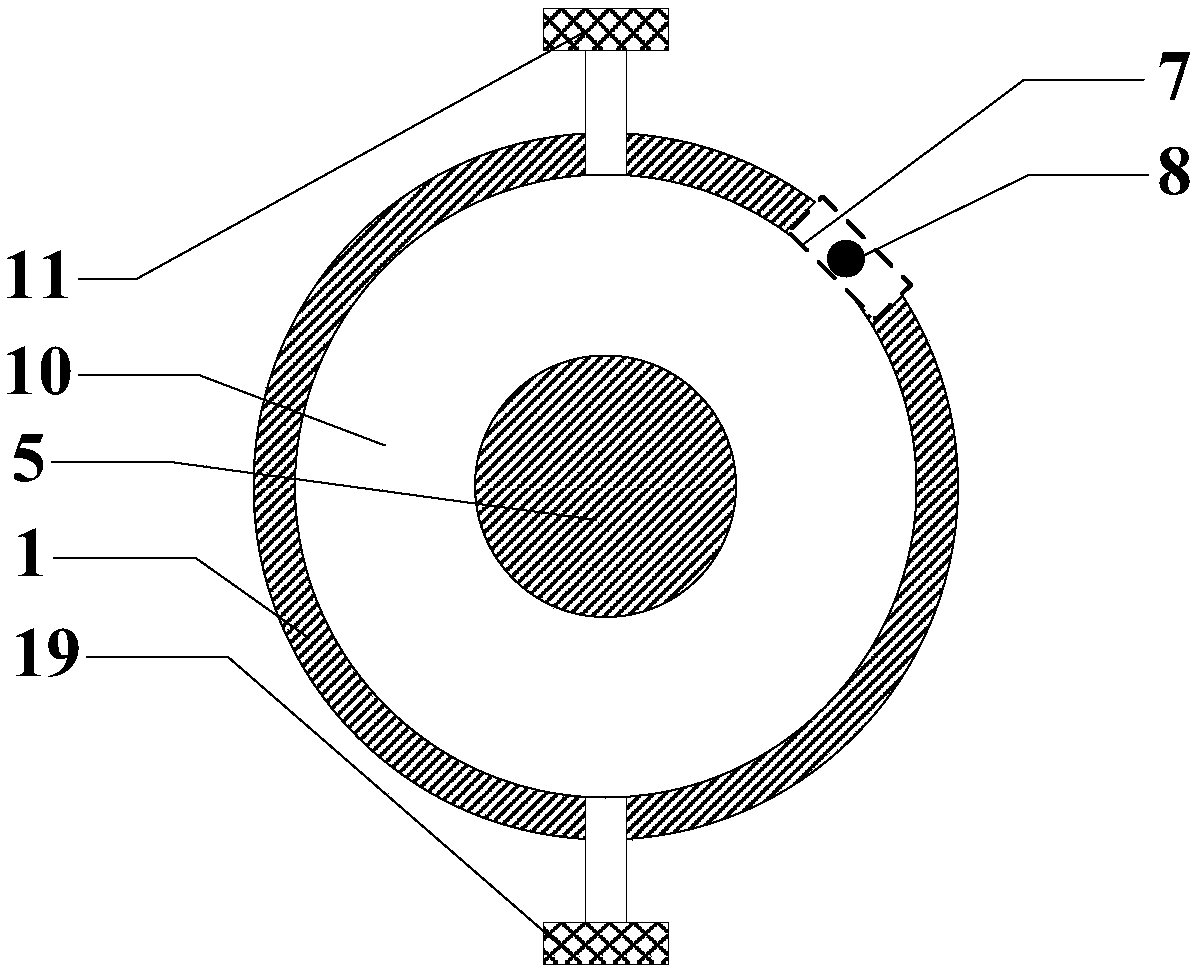

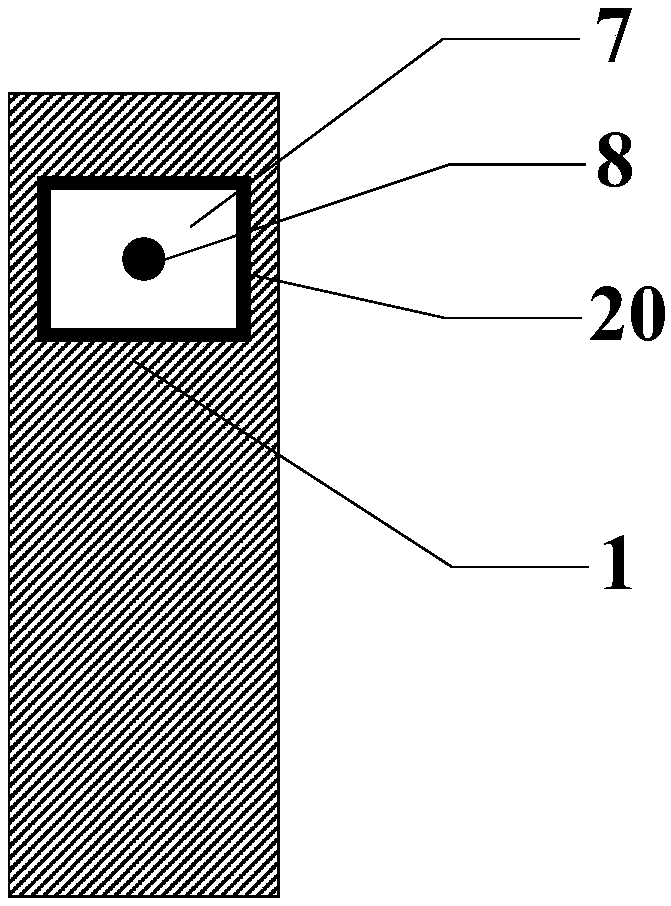

[0028] see figure 1 , a flange-type SHPB liquid-filled jointed rock sample liquid application device provided by an embodiment of the present invention includes a pressure-bearing cavity device for accommodating the end of the sample and observing the change process of the sample with the liquid And a liquid applying device for filling the sample with liquid, applying pressure and monitoring the liquid pressure. Wherein, the pressure-bearing cavity device includes a metal cavity shell 1, a metal flange 2, a metal screw 3, a first seal 4, an observation window 7, a high-speed camera device 8, and an image acquisition device 9. The liquid applied The device includes a liquid booster pump end valve 11 arranged at the upper end of the metal cavity shell 1, a liquid booster pump 14 connected to the liquid booster pump end valve 11 through a conduit 12, and arranged on the liquid booster pump 14. The static pressure gauge 13, the liquid inlet and outlet valve 19 arranged at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com