Small shunting type multi-phase flow meter and calibration method thereof

A multiphase flowmeter and split-flow technology, which is applied in the field of small split-flow multiphase flowmeter and its adjustment, can solve the problems of high adjustment cost, troublesome multiphase flow measurement, and long assembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

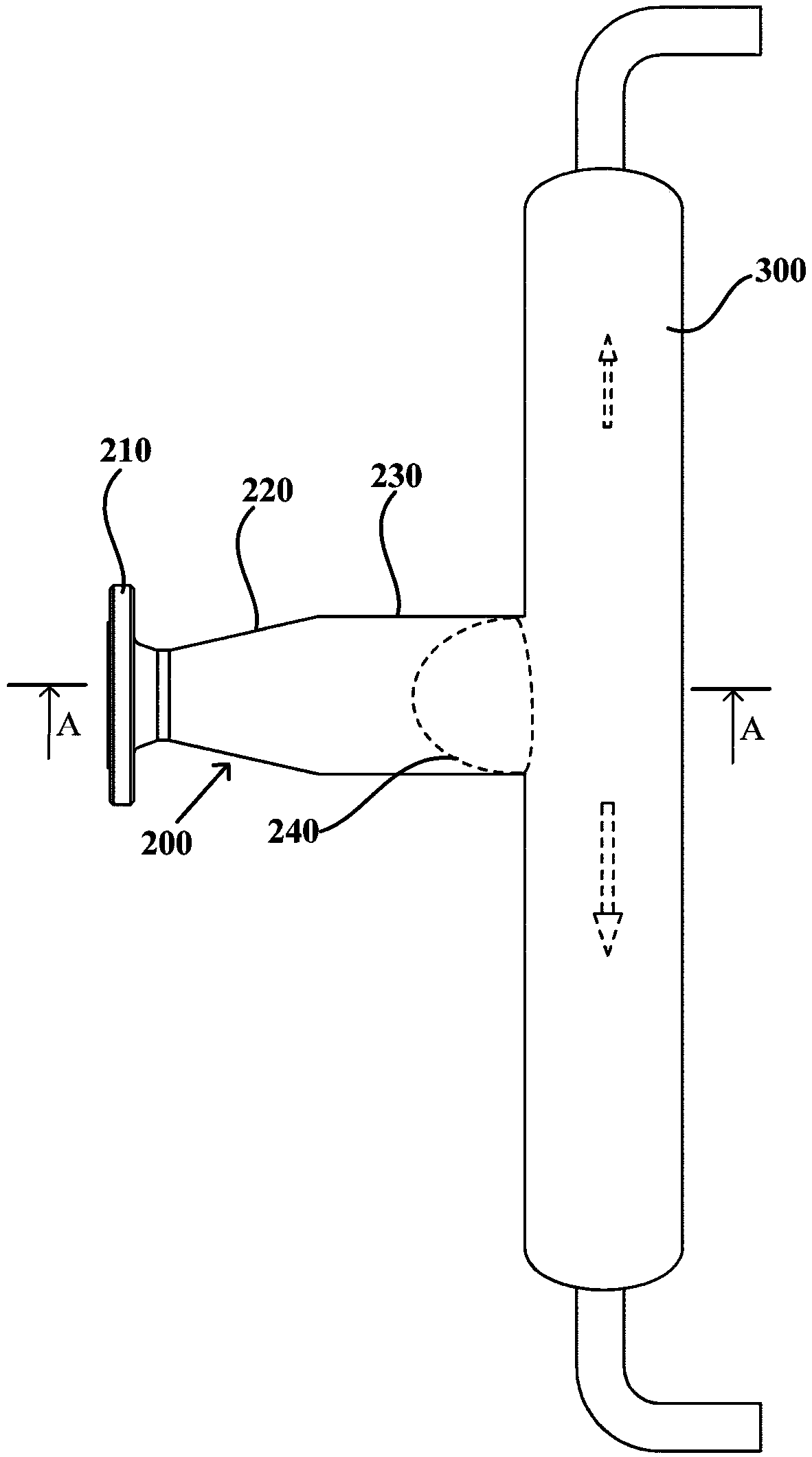

[0073] figure 1 is a schematic diagram of a small split multiphase flowmeter 10 according to one embodiment of the present invention. The small shunt multiphase flowmeter 10 can be applied to the air flow rate of 1×10 by replacing the flow sensor 4 SM 3 / d to 500×10 4 SM 3 In the range of / d, the liquid volume is 1m 3 / d to 1500m 3 In the range of / d, the pressure is in the range of 0.2-42MPa, and its specific pipeline structure may include: fluid inlet pipe 200, shunt pipe 300, first branch 500, second branch 400, and manifold 600 .

[0074] Among the above components, the fluid access pipe 200 is used for accessing gas-liquid fluid. The fluid access pipe 200 may include: a connecting flange 210 , a diameter-expanding pipe section 220 , and a main pipe section 230 . The connecting flange 210 is used for connecting the fluid input pipe, which is suitable for the fluid input pipe. The diameter-expanding pipe section 220 is connected to the connecting flange 210 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com