Centrifugal variable-capacity type compressed gas compressor and method

A compressed gas, variable capacity technology, applied in non-variable capacity pumps, non-displacement pumps, liquid fuel engines, etc., can solve the problems of low compression efficiency, parts wear and energy consumption, raw material requirements and processing accuracy requirements. , to achieve the effect of long practical life, high energy efficiency ratio and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and beneficial effects of the present invention, the technical solutions of the present invention are now described in detail below, but this should not be construed as limiting the scope of the present invention.

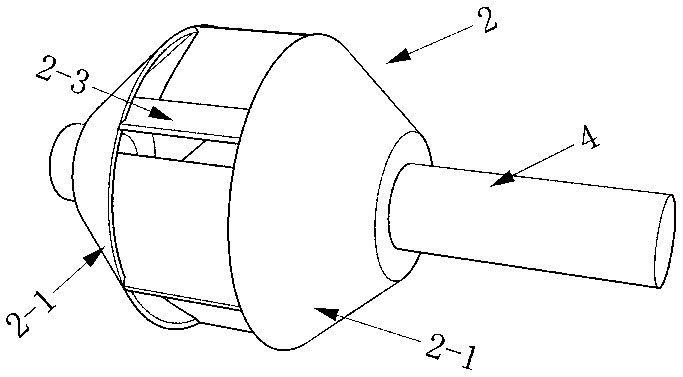

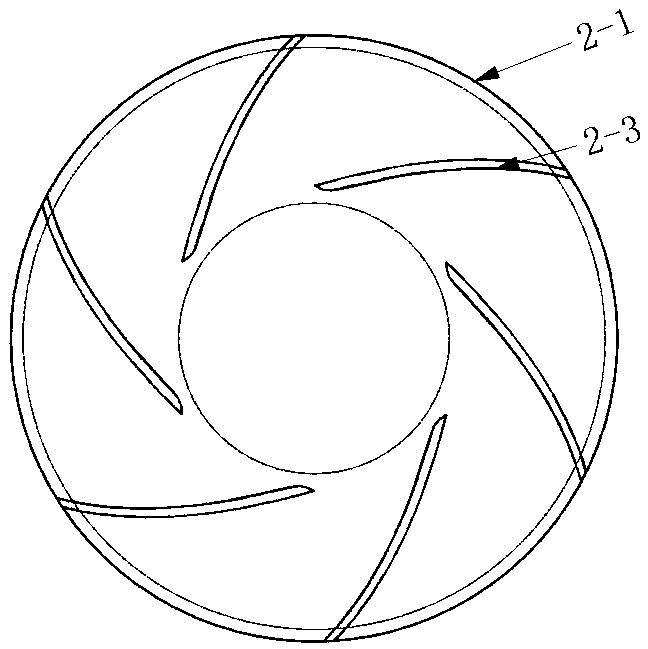

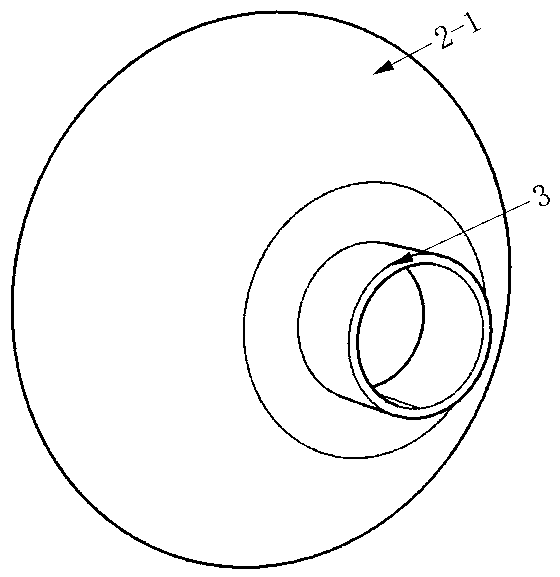

[0025] As shown in the figure, a centrifugal variable capacity compressed gas compressor includes a casing 1 and a compression disc 2; it is characterized in that the inner cavity of the casing 1 is a barrel-shaped structure; A shaft hole 1-1 is opened, and an exhaust hole 1-2 is opened on the side of the casing 1, which is used to discharge the compressed gas to the outside; the two sides of the compression disc 2 are buckle-shaped disc covers 2- 1. The two disk covers 2-1 are fixed by embankment-shaped blades 2-3, and the disk cover 2-1 and embankment-shaped blades 2-3 form a whole. During the high-speed rotation of the compression disk 2, the gas is subjected to centrifugal force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com