Tesla turbine and control method

A Tesla turbine and shaft technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as large power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Such as figure 1 As shown, a Tesla turbine comprising:

[0115] Shaft 100;

[0116]A housing 200 disposed on the rotating shaft 100, the housing 200 is provided with a medium inlet (not shown in the figure) and a medium outlet (not shown in the figure);

[0117] Several disks 300 are arranged in the housing 200, and several disks 300 are fixedly connected to the rotating shaft 100. A gap 400 is provided between every two adjacent disks 300 among the several disks 300. Each of the disks 300 is provided with at least one exhaust hole 301;

[0118] And, the thrust bearing 500 and at least two radial bearings disposed on the rotating shaft 100 are non-contact bearings.

[0119] In the embodiment of the present invention, the rotating shaft 100 of the Tesla turbine can be connected with the motor 3 , for example, the rotating shaft 100 is connected with the rotating shaft 310 of the motor 3 through the coupling 7 . Of course, the motor 3 can also be directly arranged on ...

Embodiment 2

[0143] The working process of the Tesla turbine is described in detail below.

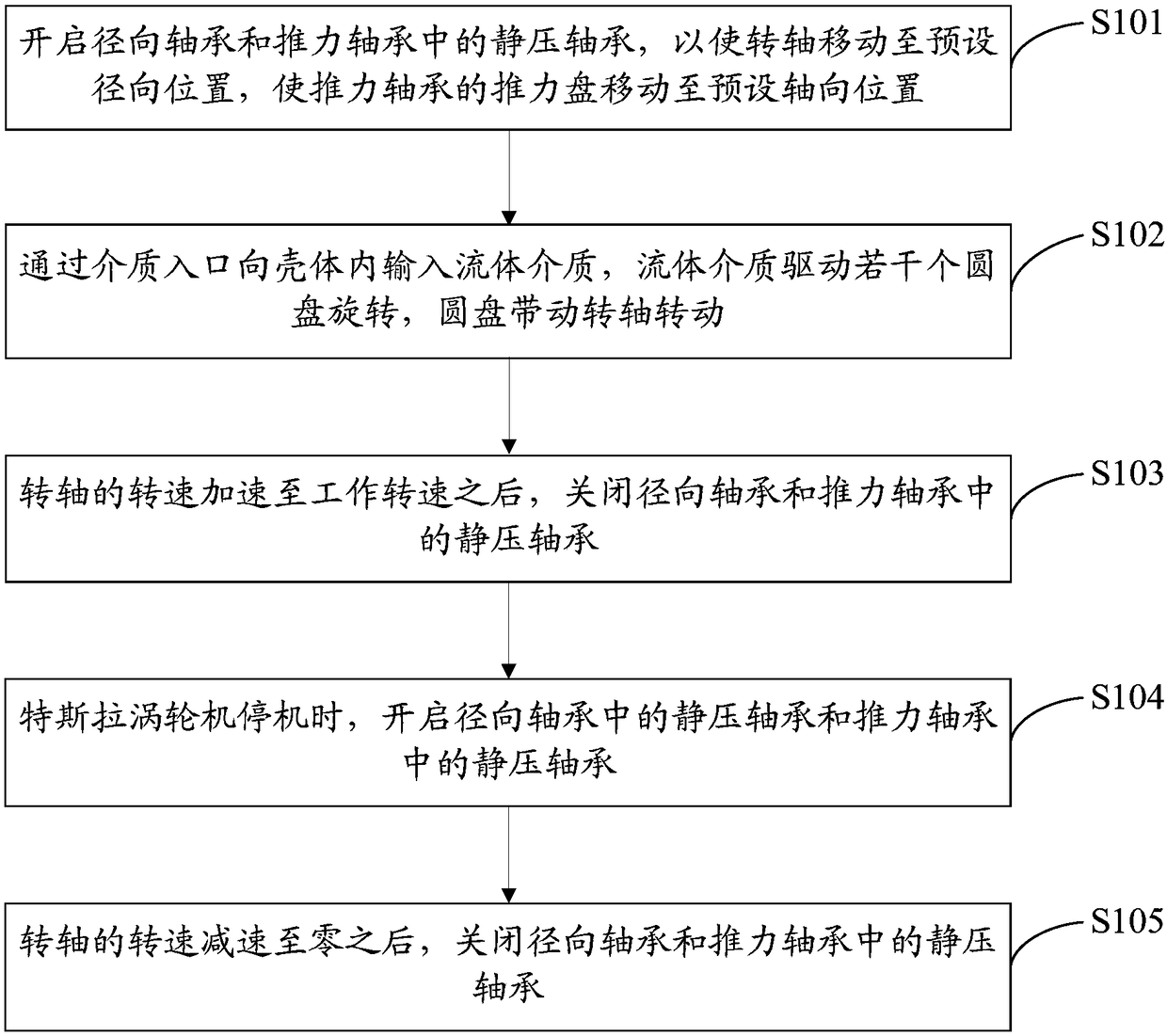

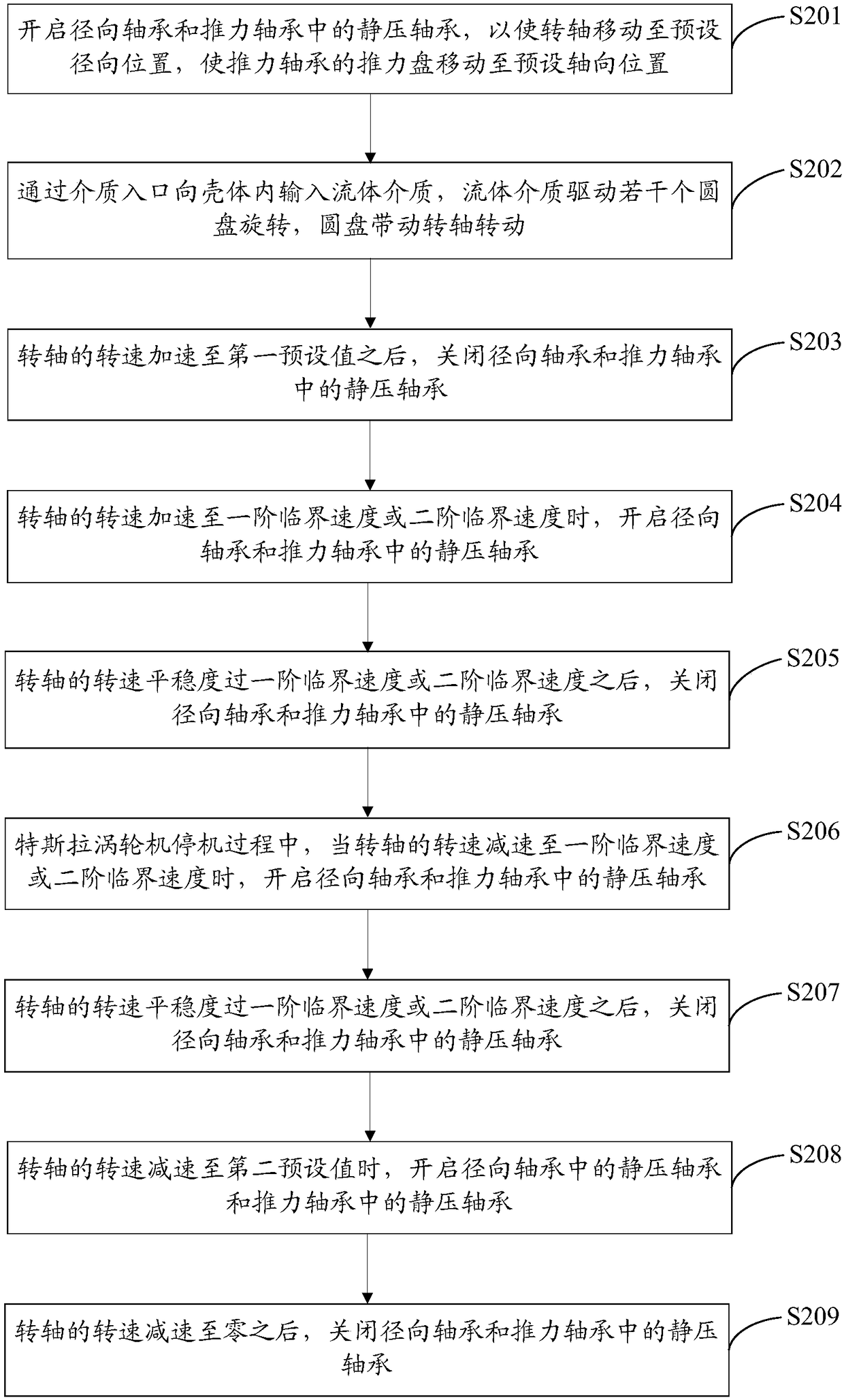

[0144] As mentioned above, the thrust bearing in the Tesla turbine can use aeromagnetic hybrid thrust bearing, and the radial bearing can use aeromagnetic hybrid thrust bearing or aerodynamic and static pressure hybrid radial bearing. For the convenience of description, we define the bearings that can lubricate without the rotation of the rotating shaft 100 as hydrostatic bearings, and the bearings that can only work when the rotating shaft 100 rotates at a certain speed are defined as dynamic pressure bearings. According to this logic, the magnetic bearing and the gas static pressure bearing in the gas magnetic hybrid thrust bearing, and the gas static pressure bearing in the gas dynamic and static pressure hybrid radial bearing can all be called hydrostatic bearings; and the gas in the gas magnetic hybrid thrust bearing Both the hydrodynamic bearing and the gas dynamic pressure bearing in the gas...

Embodiment 3

[0177] Figure 4 to Figure 7 Schematic diagram of the structure of the foil-type aeromagnetic hybrid thrust bearing provided by the embodiment of the present invention.

[0178] Such as Figure 4 to Figure 7 As shown, the foil type aeromagnetic hybrid thrust bearing 5100 includes:

[0179] The first thrust plate 5101, the first thrust plate 5101 is fixedly connected to the rotating shaft 100;

[0180] And, the first stator 5102 and the second stator 5103 passing through the rotating shaft 100, the first stator 5102 and the second stator 5103 are respectively arranged on opposite sides of the first thrust plate 5101;

[0181] In the first stator 5102 and the second stator 5103, each stator includes a first magnetic bearing 5104 and a first foil bearing 5105, the first magnetic bearing 5104 is provided with a plurality of first magnetic components along the circumferential direction, and the first foil The sheet bearing 5105 is provided with a second magnetic component capabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com