LongitudinaL shunting structure for drivage based on soft rock bottom pLate

A roadway and bottom plate technology, which is applied in the field of roadway excavation longitudinal shunting structure, can solve the problems of increasing the cost of excavation, increasing the length of track laying, and the inability to realize parallel operations, etc., and achieve the goal of reducing investment, reducing the length of track laying, and reducing the amount of roadway excavation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

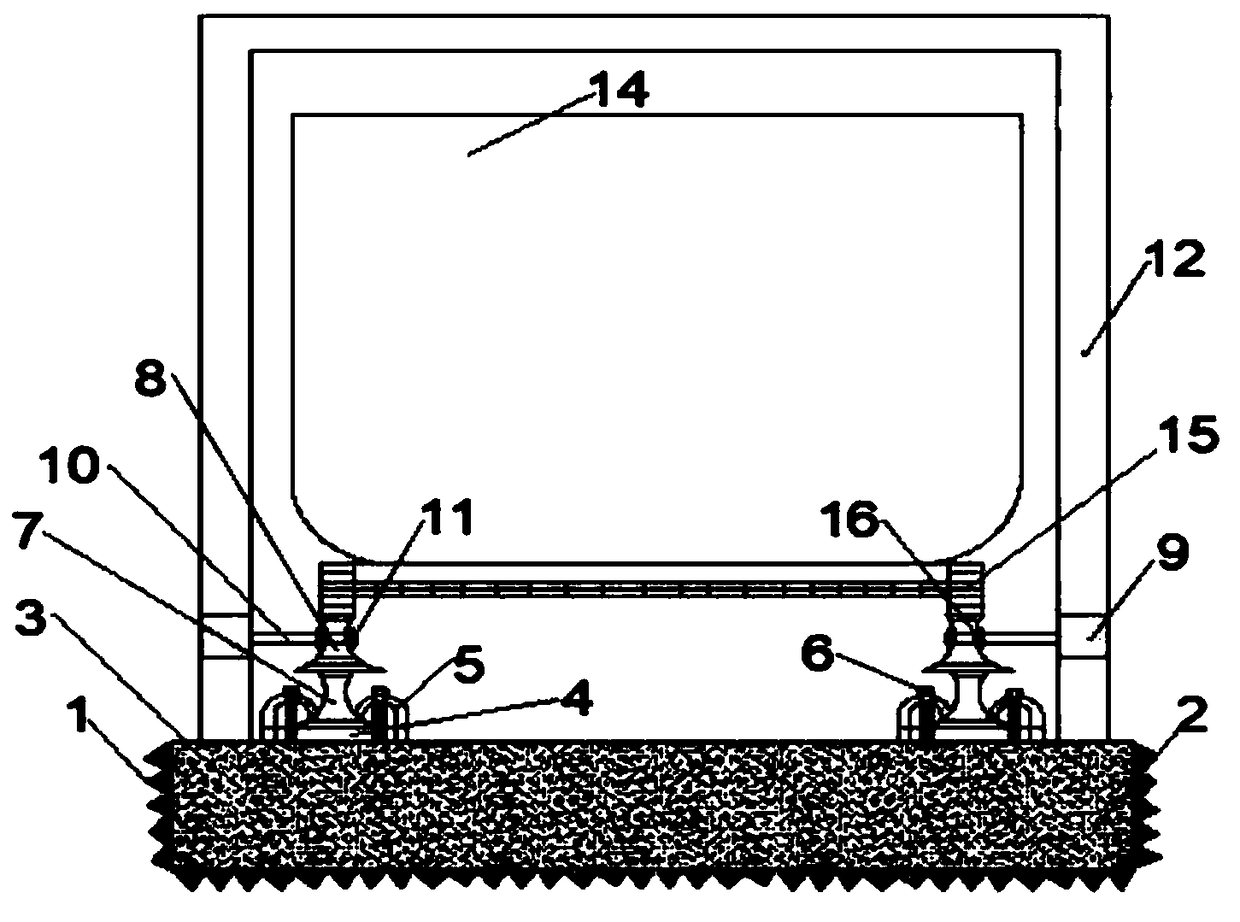

[0011] This embodiment provides a roadway excavation longitudinal shunting structure based on soft rock floor, including a concrete track slab 3 laid on the bottom of the roadway, rubber pads 1 under the slab are filled between the concrete track slab 3 and the bottom and side walls of the roadway, and the concrete Two under-rail damping pads 4 are laid on the track slab 3 along the length direction of the roadway, and fixed rails 7 are respectively laid on the under-rail damping pads 4, and the fixed rails 7 are fixed on the concrete track slab 3 through rail fasteners 5, The rail fastener 5 is locked and fixed on the concrete track slab 3 by the bolt 6, and the upper end of the fixed rail 7 is correspondingly laid with a lifting rail 8, and the wheel pairs 15 at the bottom of the carriage 14 are respectively set on the lifting rail 8, and the lifting rail 8 passes through the horizontal The provided rail connecting rod 10 is fixedly connected with the lifting part 9 of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com