Polarization-regulating energy-saving vertical sealing device

A sealing device and well sealing technology, which is applied to the components of the pumping device for elastic fluid, drilling equipment, sealing/packing, etc. Shut down, increase the power consumption of the pumping unit, etc., to achieve good energy-saving effect, shorten the replacement cycle, and save the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

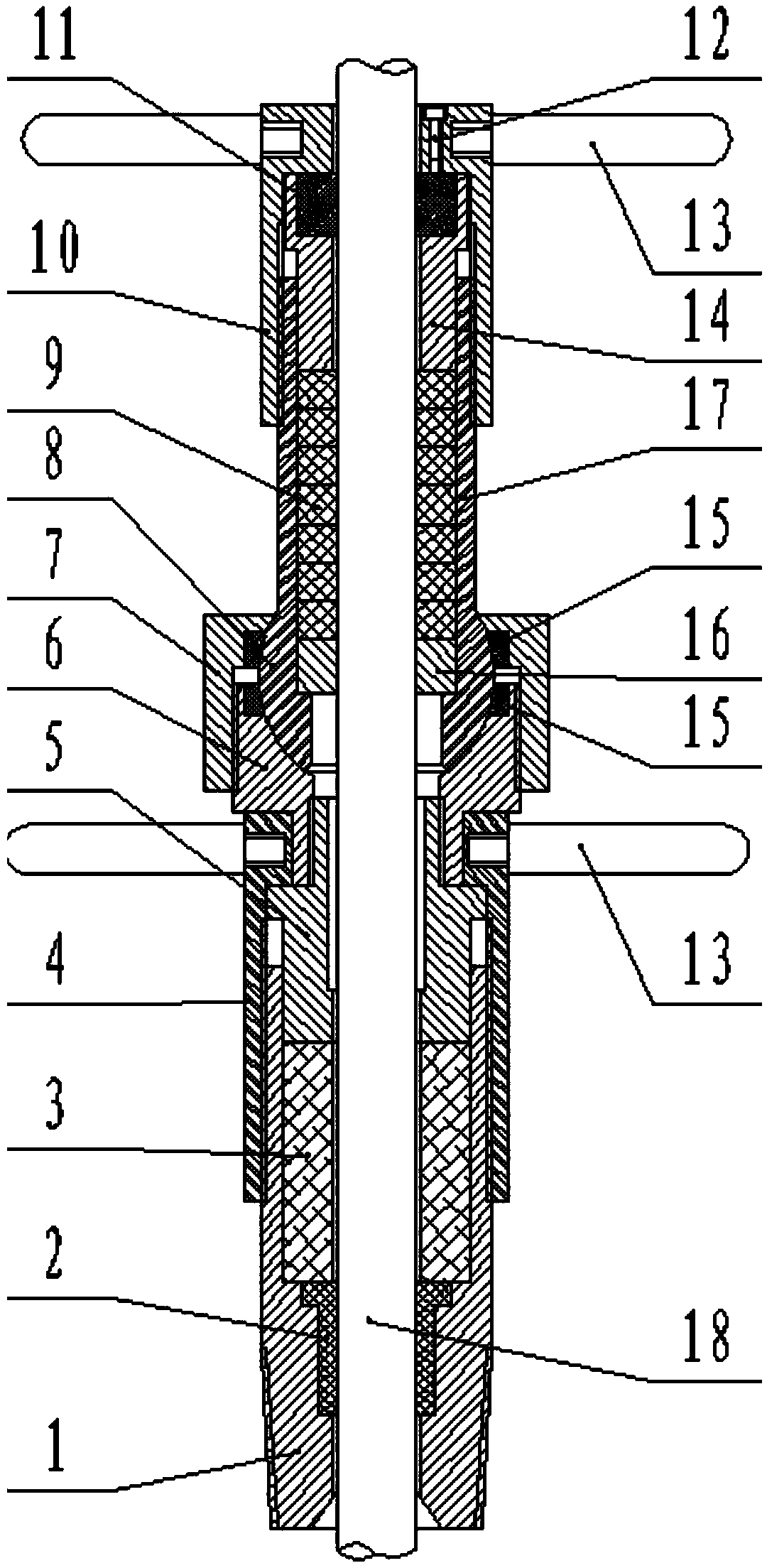

[0015] The present invention will be further described below in conjunction with accompanying drawing:

[0016] The present invention includes a polished rod sealing device and a well sealing device, and the oil pumping polished rod 18 is passed through the center of the polished rod sealing device and the well sealing device. The above is a conventional structure in the prior art, and will not be repeated here.

[0017] The polished rod sealing device includes an adjustment sleeve 10, a packing gland 14, a packing 9, a support ring 16 and a packing box 17, and the adjusting sleeve 10 is connected to the upper end of the packing box 17 by threads, and the packing pressure The cover 14, the packing 9 and the support ring 16 are packaged in the annular space surrounded by the adjustment sleeve 10, the packing box 17 and the oil sucking rod 18 in order from top to bottom. After the packing 9 wears out, the contact pressure between the packing 9 and the polished oil rod 18 decrea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com