Waterproof connecting structure of deformation joint of building roof

A technology for connecting structures and deformation joints, applied in building roofs, building structures, building components, etc., can solve the problems of many processes, uneven levels, complex construction, etc., to achieve convenient operation, easy installation and replacement, assembly and other problems. The effect of easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

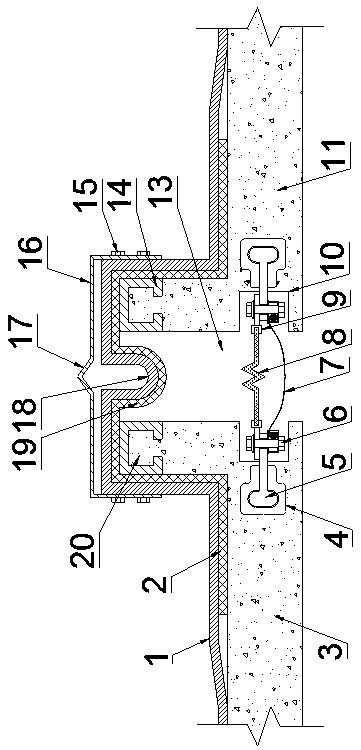

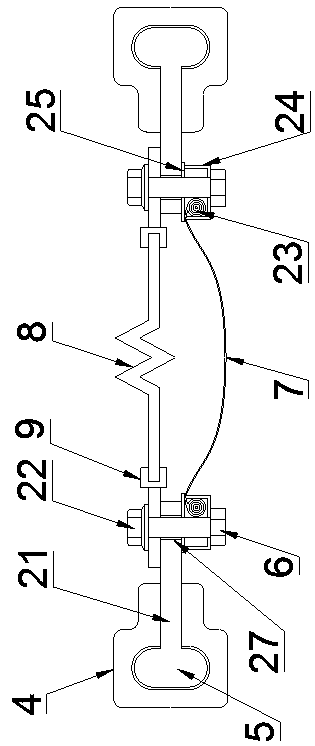

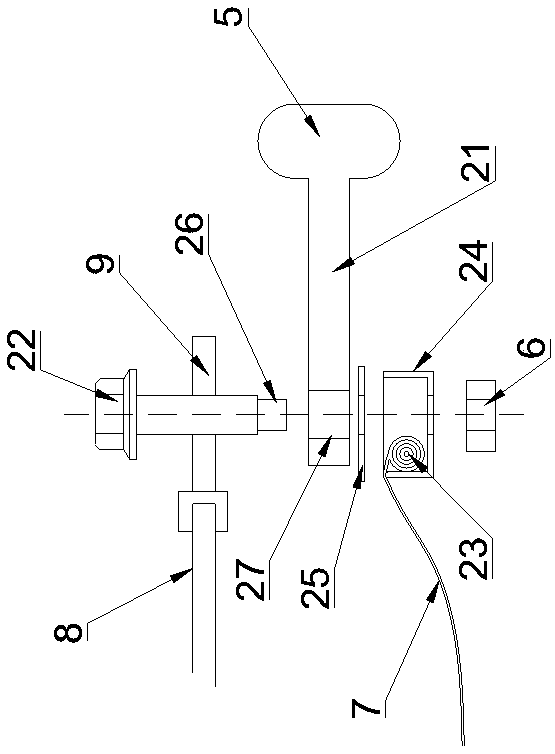

[0021] see Figure 1-Figure 3 , a waterproof connection structure for deformation joints on the roof of a building, comprising a waterproof roll material layer 1, a fireproof rock wool layer 2, a waterproof elastic material connection belt 7, an elastic rubber belt 8, a deformation joint 13 and a waterproof aluminum plate 16, the deformation joint 13 It is arranged between the first concrete wall 3 and the second concrete wall 12, and the tops of the first concrete wall 3 and the second concrete wall 12 are provided with heightened reinforced concrete walls 20, and the tops of the reinforced concrete walls 20 are provided with profiled steel edging 14 , the shaped steel edging 14 is wrapped on the top of the reinforced concrete wall 20 to enhance its structural strength.

[0022] The top of the deformation joint 13 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com