Highway guardrail used for municipal engineering

A highway guardrail and guardrail technology, which is applied in the directions of roads, roads, and road safety devices, can solve the problems that affect the overall appearance of the highway guardrail, the highway guardrail cannot be automatically restored to its original state, and the maintenance of the guardrail is troublesome.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

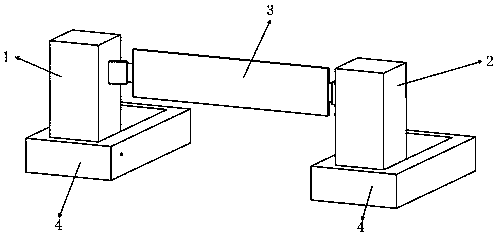

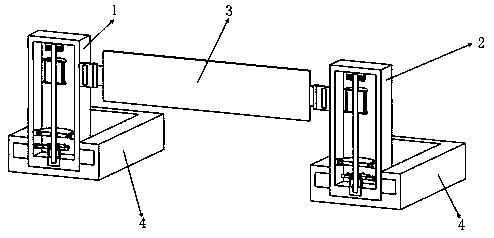

[0080] Specific embodiments: In the present invention, the bases 4 of the first guardrail mechanism 1 and the second guardrail mechanism 2 are fixedly installed on the roadbed of the road. A whole guardrail is formed by the first guardrail mechanism 1, the second guardrail mechanism 2 and the protective plate 3. The two sides of the road can be combined together to form a complete guardrail body by adjoining and sequentially side by side. To prevent accidental impact of the vehicle.

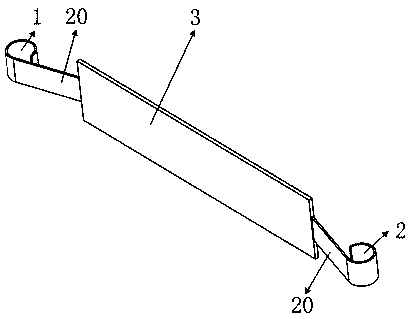

[0081] For a guardrail as a whole, when the protective plate 3 between the first guardrail mechanism 1 and the second guardrail mechanism 2 is not hit by the vehicle, one end of the protective plate 3 is in a vertical state with the guardrail square post 5, and how much is wound on the winding pulley 21 Circle buffer belt 20; When hindering piece spring 31 uncompressed, hindering piece 30 has one end of pointed angle 32 to stretch out square guide cylinder 24; The inner ring surface of the ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com