Long-filament sanding device

A sanding and filament technology, applied in the direction of textiles and papermaking, can solve the problems of poor air permeability and poor hygroscopicity, and achieve the effect of changing yarn hairiness and shortening the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

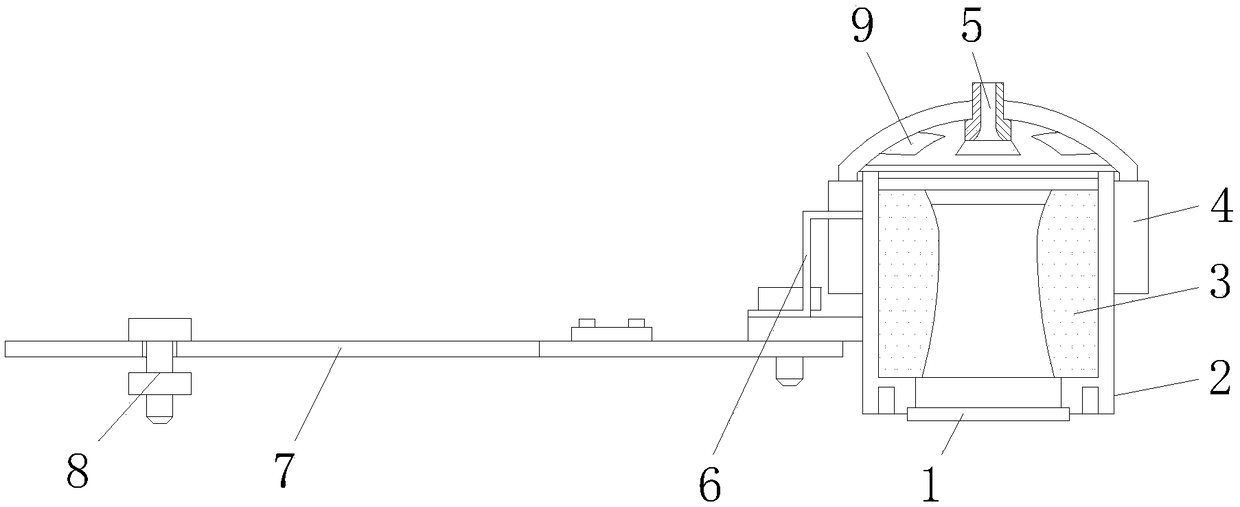

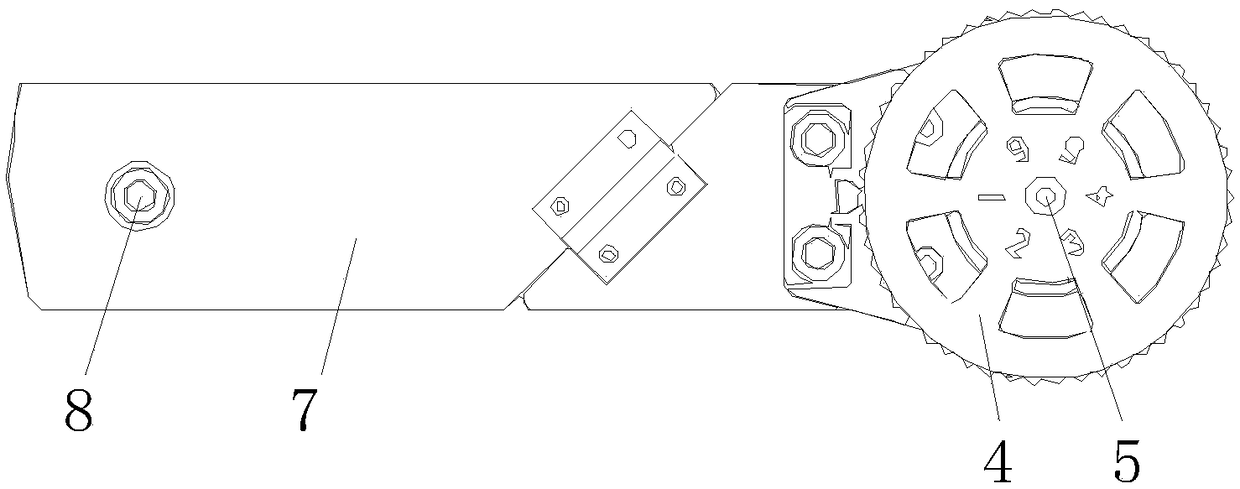

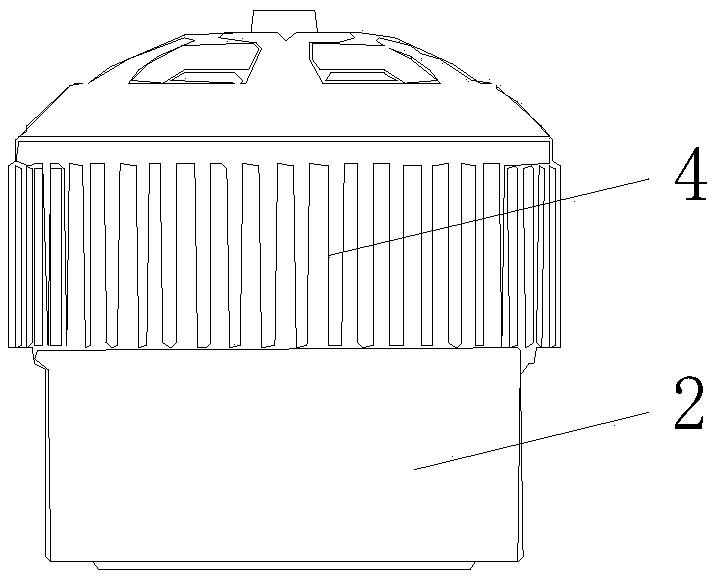

[0019] Such as Figure 1-3 , the present invention includes a lower balloon ring 1, a sanding seat 2, a sanding wheel 3, a sanding cover 4, a yarn guide porcelain piece 5, a sanding cover positioning reed 6, a fixing seat 7, a fastening screw 8 and an upper gas The ring 9 and the fixed seat 7 are divided into left and right parts, and the fixed seats 7 of the left and right parts are movably connected by a hinge, and the right end of the fixed seat 7 top is movably connected with a sanding seat 2 through a fastening screw 8, and the sanding seat 2 is movably connected to the left and right parts. The upper end on the left side of the seat 2 is movably connected with the fastening screw 8 through the sanding cover positioning reed 6, and the sanding cover positioning reed 6 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com