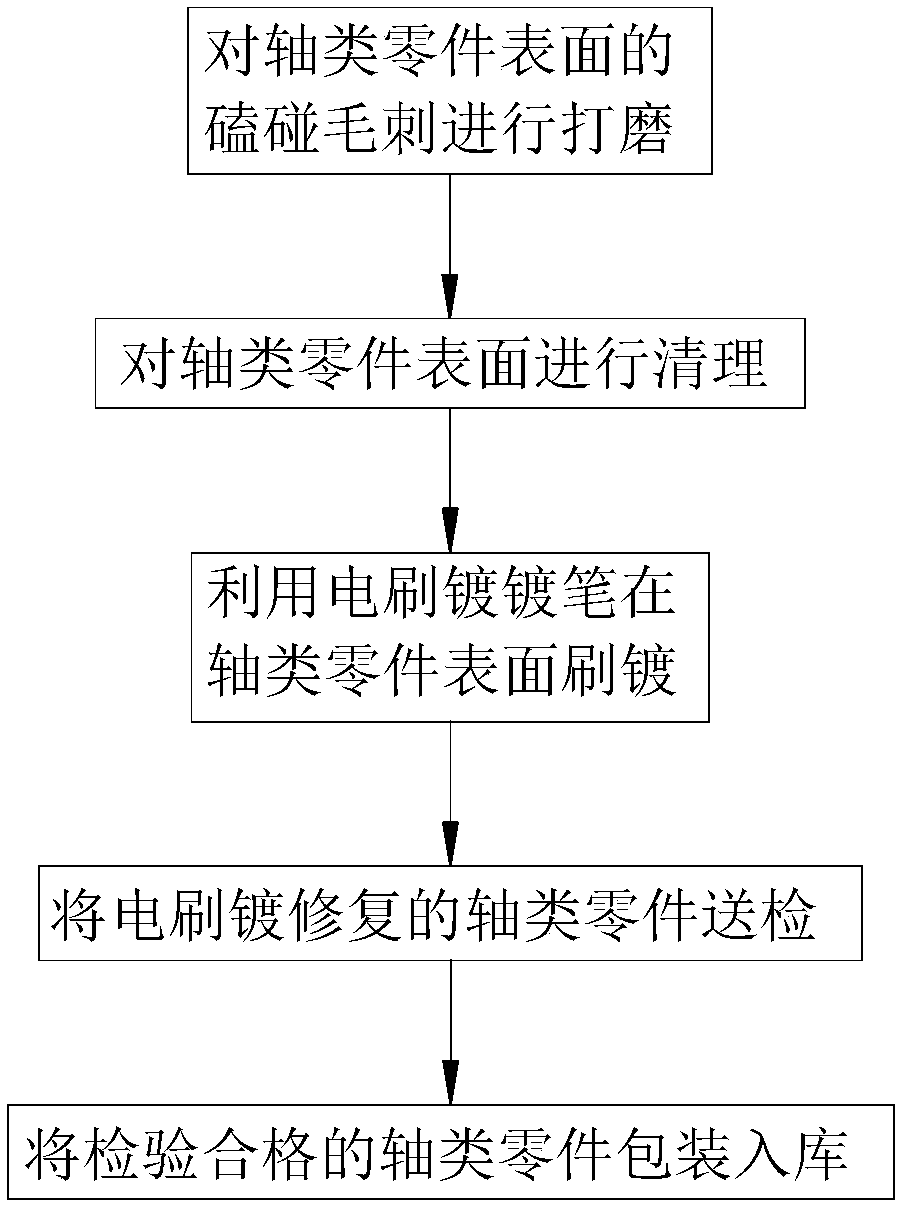

Shaft part damage repair method

A technology for repairing shaft parts and damage, applied in the field of mechanical parts repair, can solve the problems of inapplicable arc-shaped ring groove electroplating, etc., and achieve the effects of uniform thickness, improved quality and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

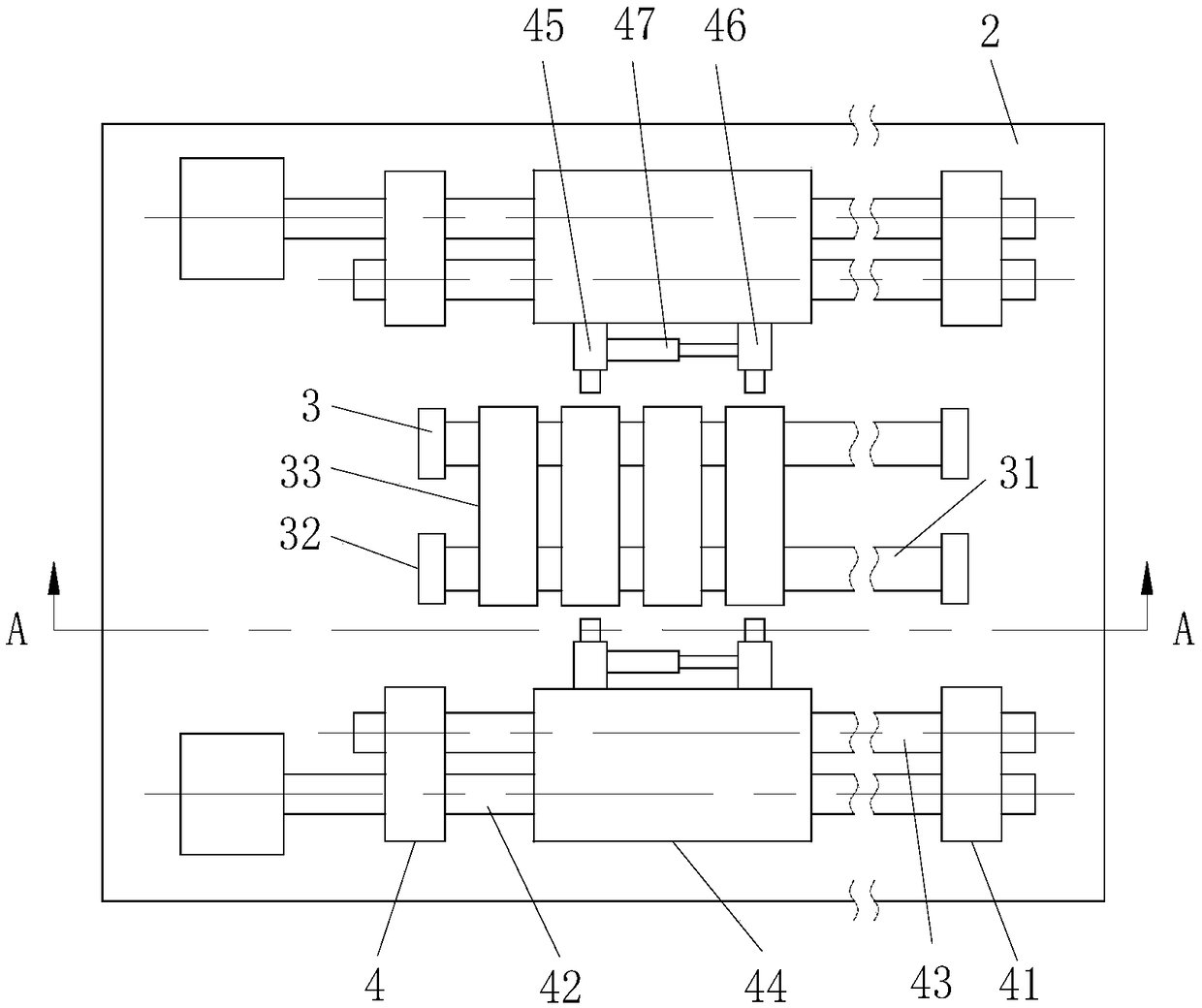

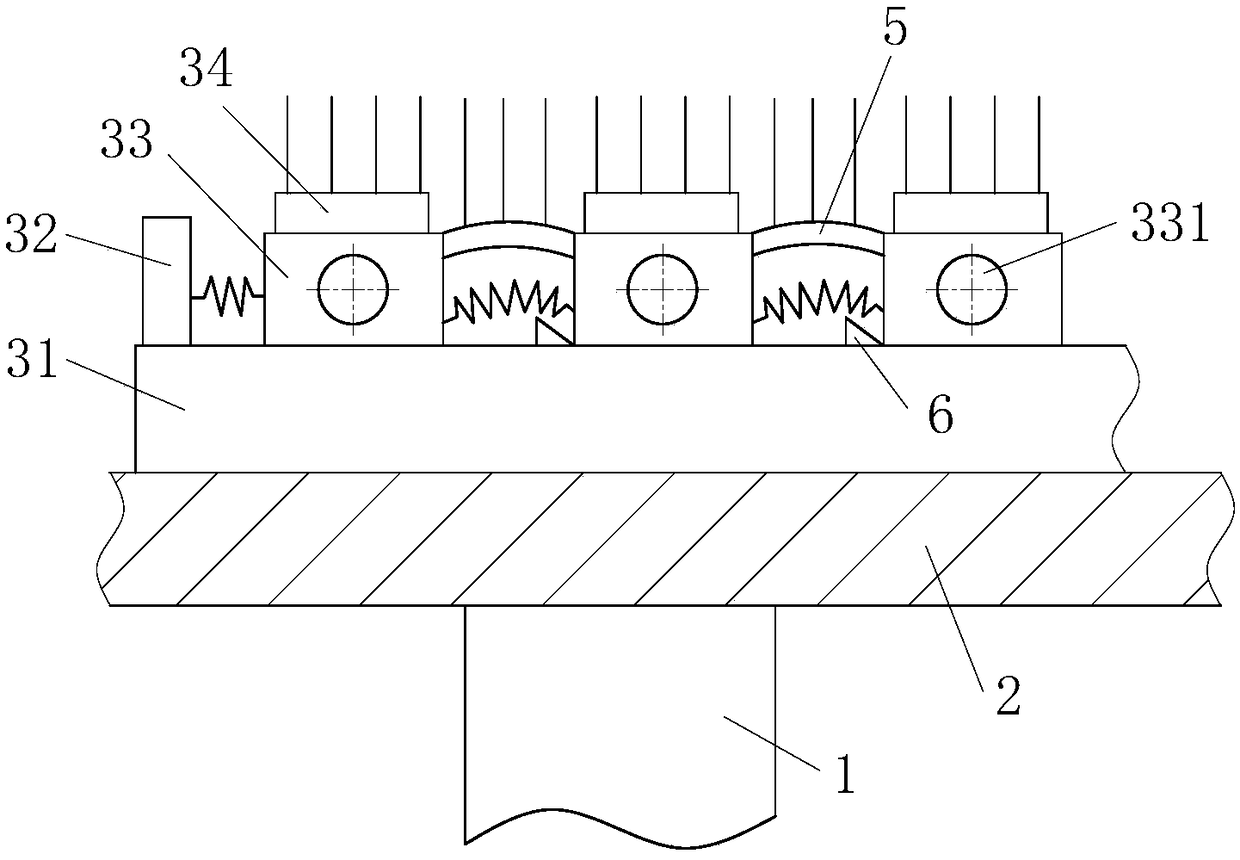

[0037] As an embodiment of the present invention, a clamping module 4 is arranged on both sides of the electroplating module 3; the clamping module 4 includes a motor, a bracket 41, a screw 42, a guide post 43, a clamping block 44, A telescopic link 45, the second telescopic link 46 and the 3rd telescopic link 47; Described support 41 is fixedly installed on the fixed plate 2; Two supports 41 are provided with leading screw 42 and guide column 43 that parallel installation, in one of them One side of the support 41 is provided with a motor, and the output shaft of the motor is fixedly connected with the screw mandrel 42; the clamping block 44 is installed on the guide post 43 and the leading screw 42; There are a first telescopic rod 45 and a second telescopic rod 46; the first telescopic rod 45 is fixedly connected to the clamping block 44, and the second telescopic rod 46 is slidably installed on the clamping block 44; the first telescopic rod 45 Between the second telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com