A composite high-strength and toughness molybdenum alloy and its preparation method

A tough molybdenum and alloy technology, applied in the field of composite high-strength tough molybdenum alloy and its preparation, molybdenum alloy, can solve the problems of insufficient comprehensive performance and single performance of molybdenum alloy, and achieve good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example provides a composite high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 5.0 g of titanium hydride, 0.8 g of zirconium hydride, 0.4 g of carbon powder, 0.4 g of boron powder, and 0.4 g of aluminum hydride. The powder is 0.4g, and the molybdenum powder is 1000g.

[0030] The preparation method of the high-strength and tough molybdenum alloy of the present embodiment comprises the following steps:

[0031] Step 1, one-time mixing: according to the proportion of the formula, the titanium hydride, zirconium hydride and composite reducing powder are mixed for 1 hour using a three-dimensional mixer;

[0032] Step 2, secondary mixing: uniformly mix titanium hydride, zirconium hydride and composite reduction powder with molybdenum powder again for 2-4 hours;

[0033] Step 3, ball milling: put the powder after the secondary mixing into a ball mill tank, fill it with argon, and ball mill for 2h in a low-energy b...

Embodiment 2

[0058] This example provides a composite high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 10.0 g of titanium hydride, 1.0 g of zirconium hydride, 0.2 g of carbon powder, 0.2 g of boron powder, The powder is 0.2g, and the molybdenum powder is 1000g.

[0059] The preparation method of the composite high-strength and tough molybdenum alloy in this example is basically the same as that in Example 1.

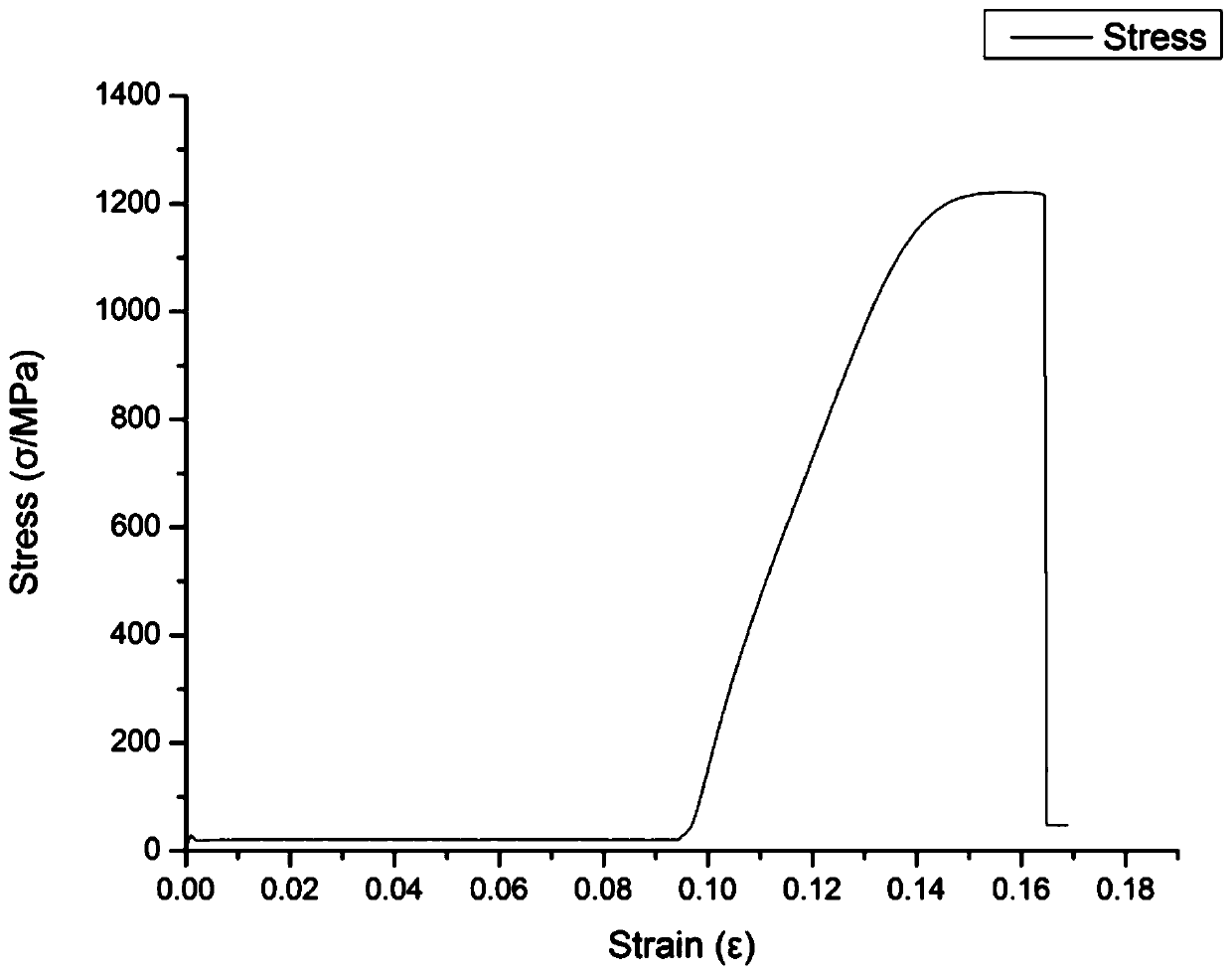

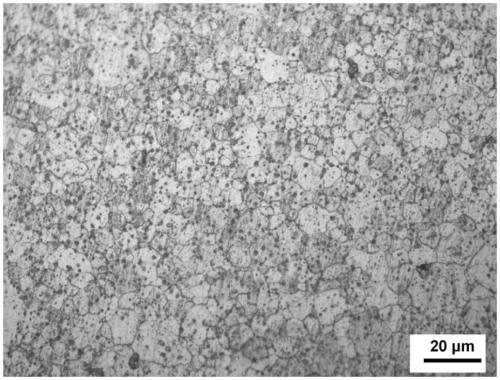

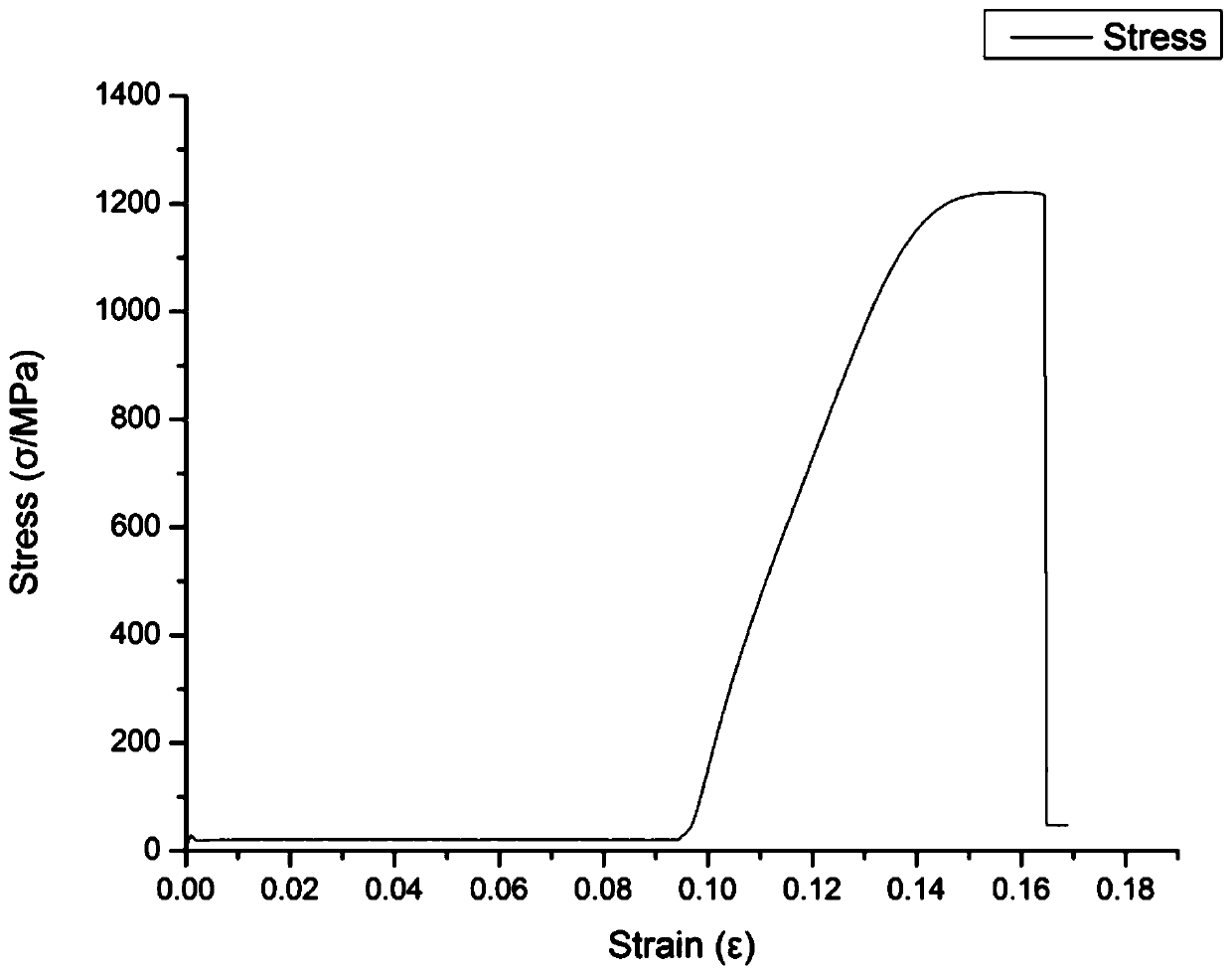

[0060] The tensile curve of the composite high-strength and tough molybdenum alloy in this embodiment is the same as figure 1 Basically the same, the SEM photo of the composite high-strength and tough molybdenum alloy in this example is the same as figure 2 basically the same.

[0061] The room temperature tensile strength of the composite high-strength and tough molybdenum alloy prepared in this example is 1218 MPa, and the elongation is 8.3%.

Embodiment 3

[0063] This example provides a composite high-strength and tough molybdenum alloy, which is made of the following raw materials in parts by weight: 20.0 g of titanium hydride, 2.0 g of zirconium hydride, 0.4 g of carbon powder, 0.4 g of boron powder, and 2.0 g of aluminum hydride. The powder is 0.4g, and the molybdenum powder is 1000g.

[0064] The preparation method of the composite high-strength and tough molybdenum alloy in this example is basically the same as that in Example 1.

[0065] The tensile curve of the composite high-strength and tough molybdenum alloy in this embodiment is the same as figure 1 Basically the same, the SEM photo of the high-strength and tough molybdenum alloy in this example is the same as figure 2 basically the same.

[0066] The room temperature tensile strength of the composite high-strength and tough molybdenum alloy prepared in this example is 1220 MPa, and the elongation is 8.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com