Aluminum alloy sheet having high mold-ability

An aluminum alloy plate and formability technology, applied in the field of Al-Mg-Si series aluminum alloy plate, can solve the problems of high formability, failure to achieve, and reduce the strength of 6000 series aluminum alloy plate, and achieve the effect of high formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

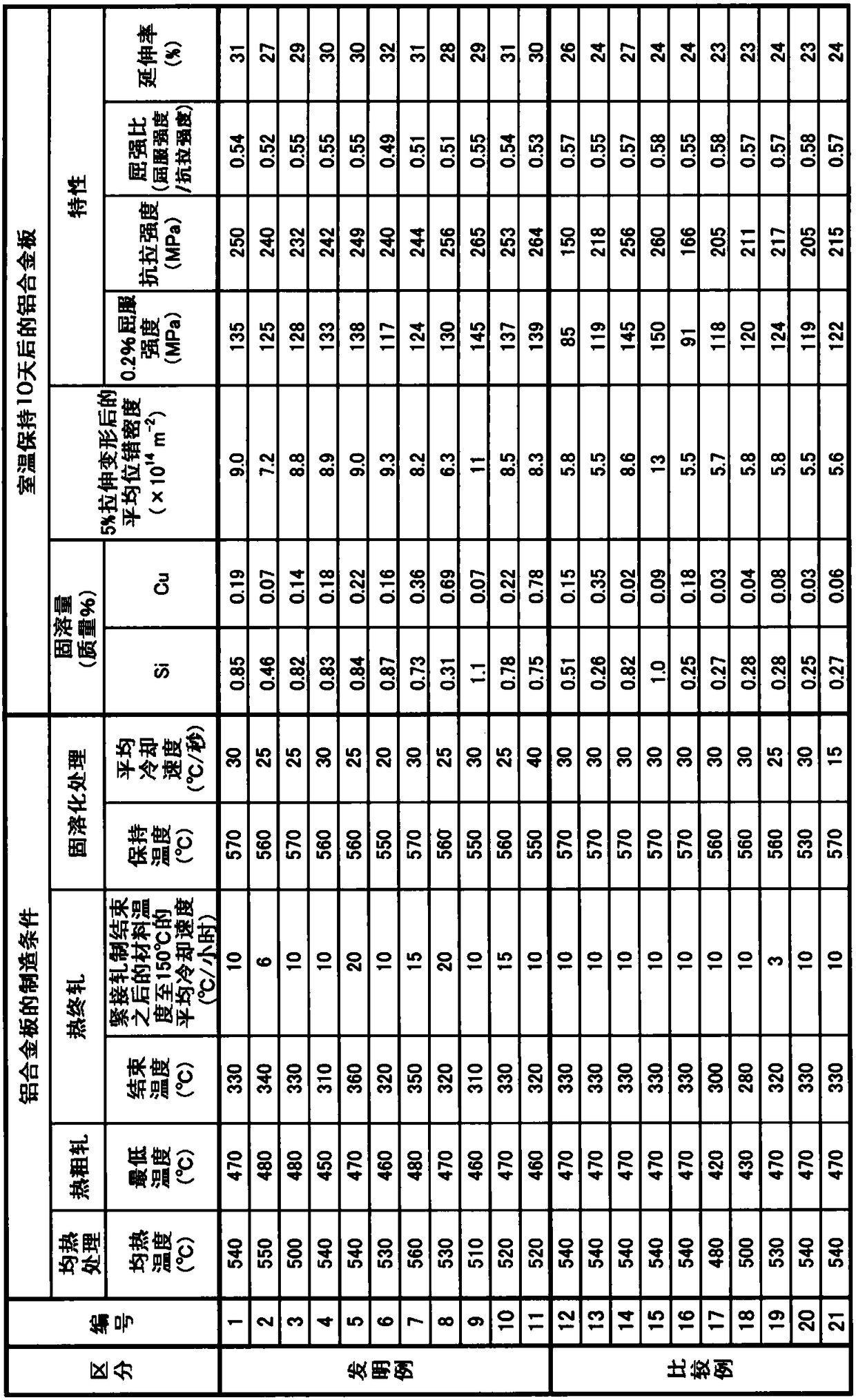

[0160] Next, examples of the present invention will be described. Like the composition shown in Table 1 and the structure shown in Table 2, the composition, the amount of solid solution Si, and the amount of solid solution Cu were produced by changing the manufacturing conditions, and the dislocation density when 5% tensile deformation was applied 6000 series aluminum alloy plates with different structures.

[0161] Then, the amount of solid-solution Si, the amount of solid-solution Cu, the dislocation density when a 5% tensile deformation was applied, the 0.2% yield strength, Tensile strength, yield ratio (0.2% yield strength / tensile strength), total elongation. These results are also shown in Table 2. Here, Table 2 follows Table 1, and the alloy numbers in Table 1 and the numbers in Table 2 correspond to each other the same.

[0162] Specifically, in the separate production method, for the 6000-series aluminum alloy sheet with the chemical composition shown in Table 1, as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com